Transversely symmetrical propeller for ship

A propeller and transverse technology, applied in the direction of rotating propellers, ship propulsion, ship components, etc., can solve the problems of increased draft, power loss, and water resistance at the stern, so as to improve energy efficiency, reduce power loss, and improve propulsion force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

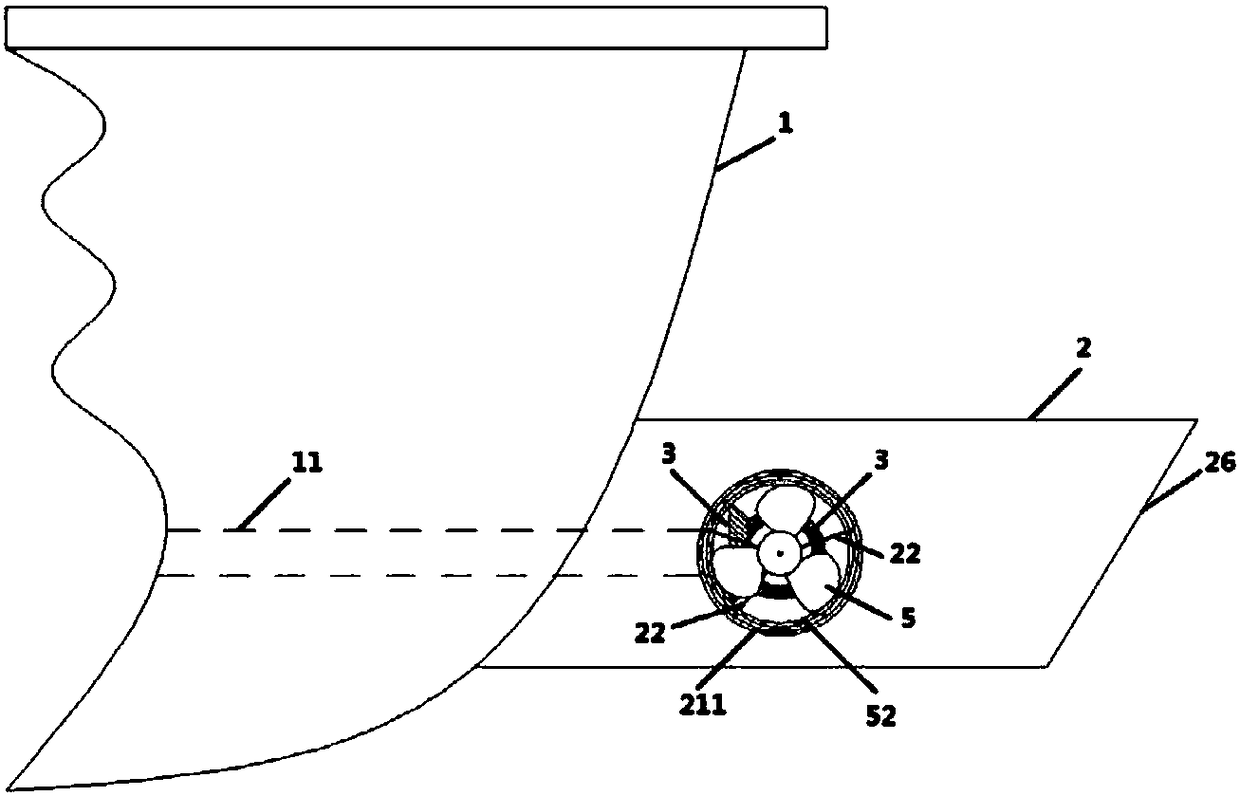

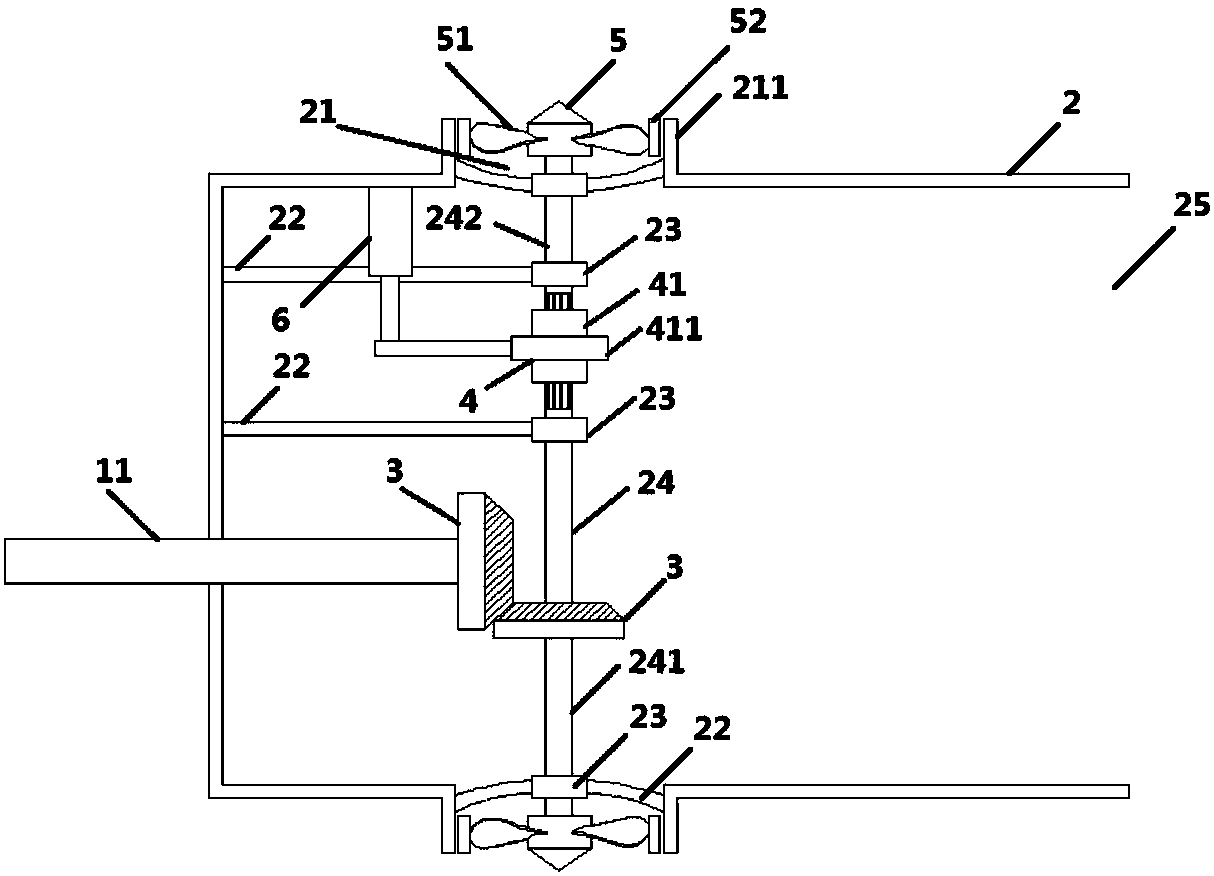

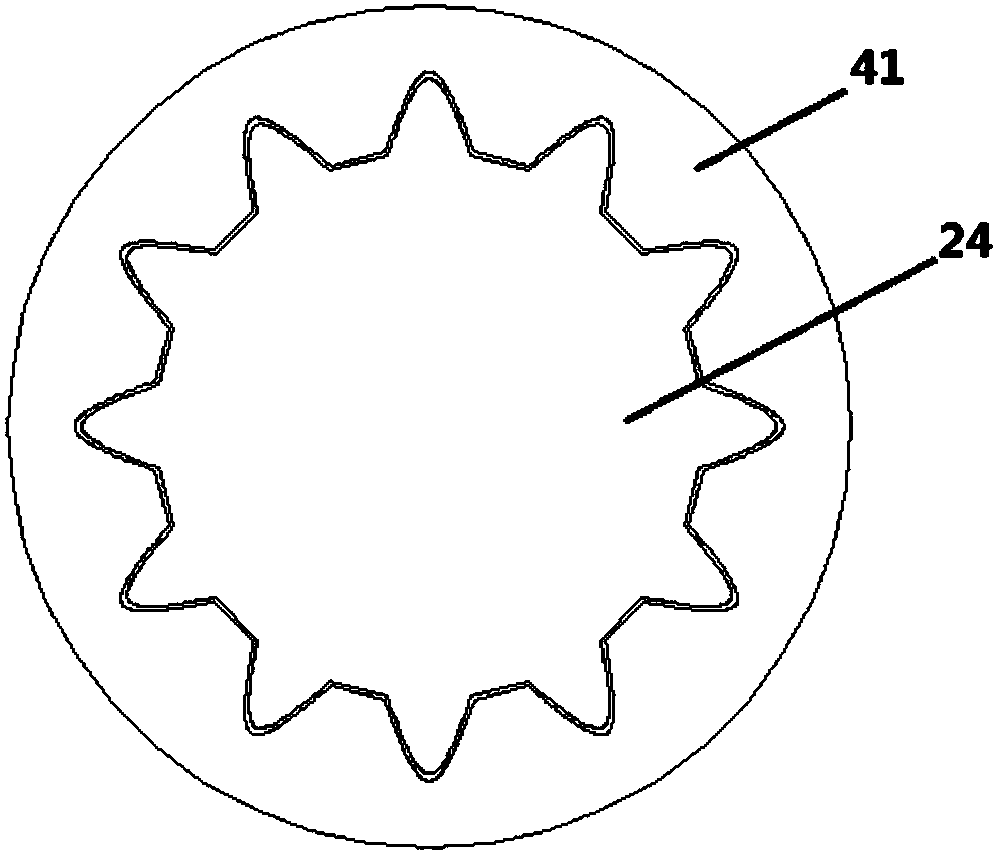

[0033] A transverse symmetrical propeller for ships, such as figure 1 , 2 , 3, including box 2, box 2 is installed in the afterbody of hull 1, and the afterbody of box body 2 is provided with inlet and outlet 25, and the transmission main shaft 11 inside hull 1 extends into box body 2 from front to back, and transmission The end of the main shaft 11 is provided with a coaxial bevel gear 3, and the left and right sides of the box body 2 are provided with corresponding round holes 21, and a horizontal axis is provided at the connecting line between the centers of the two round holes 21. 24, the horizontal shaft 24 is covered with a plurality of bearings, the bearings are arranged in the bearing seat 23, the bearing seat 23 is fixed to the end of the pole 22, and the other end of the pole 22 is fixed on the inner wall of the box body 2, said The horizontal shaft 24 includes a drive shaft 241 and a driven shaft 242 connected by a clutch 4, the drive shaft 241 is provided with a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com