Unmanned aerial vehicle (UAV) for logistics, and working method of UAV

A UAV and logistics technology, applied in the field of UAV, can solve the problems of large interference resistance and pressure difference resistance, affecting flight safety, hidden danger of cargo loss, etc., to reduce the volume and weight, avoid warehouse vibration, ensure The effect of cargo security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

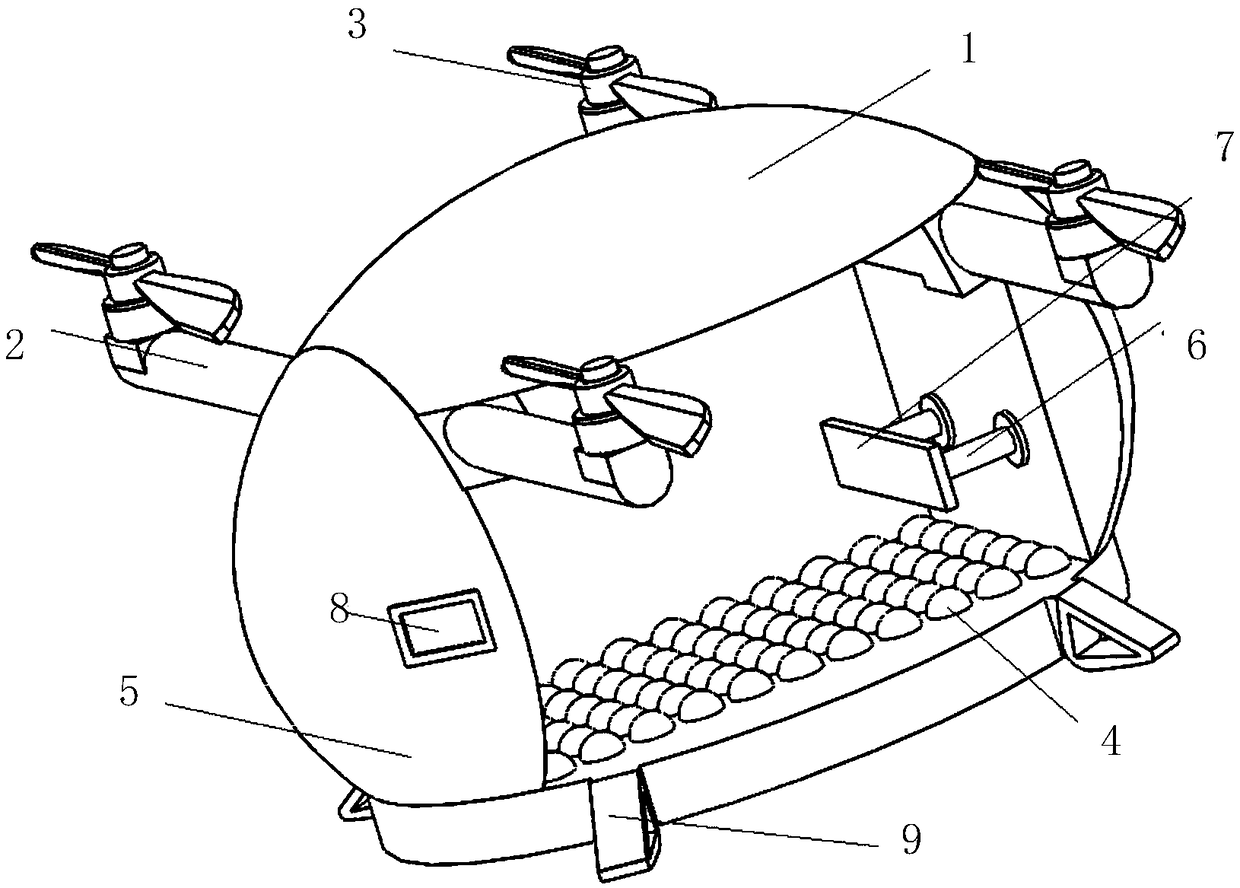

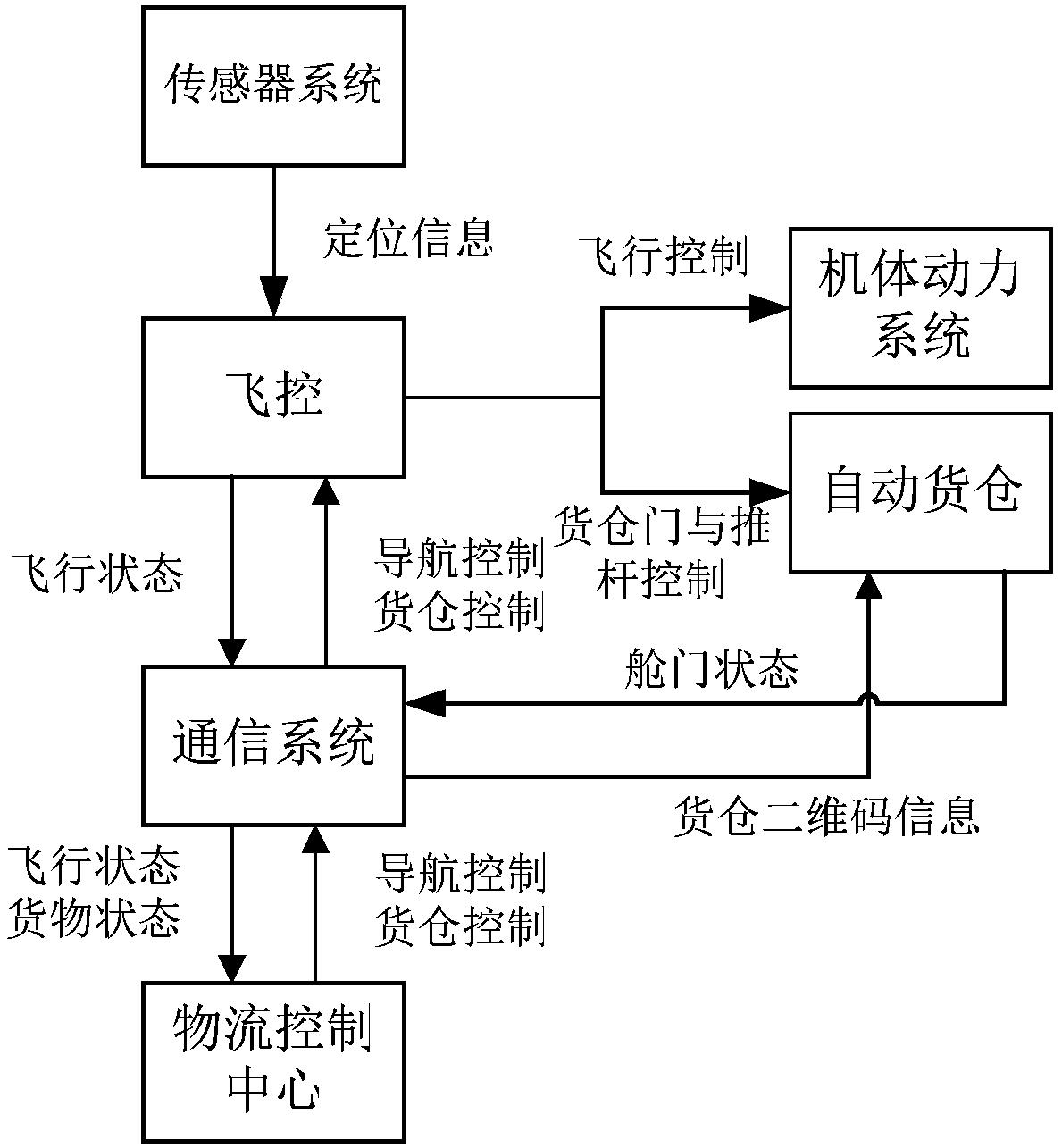

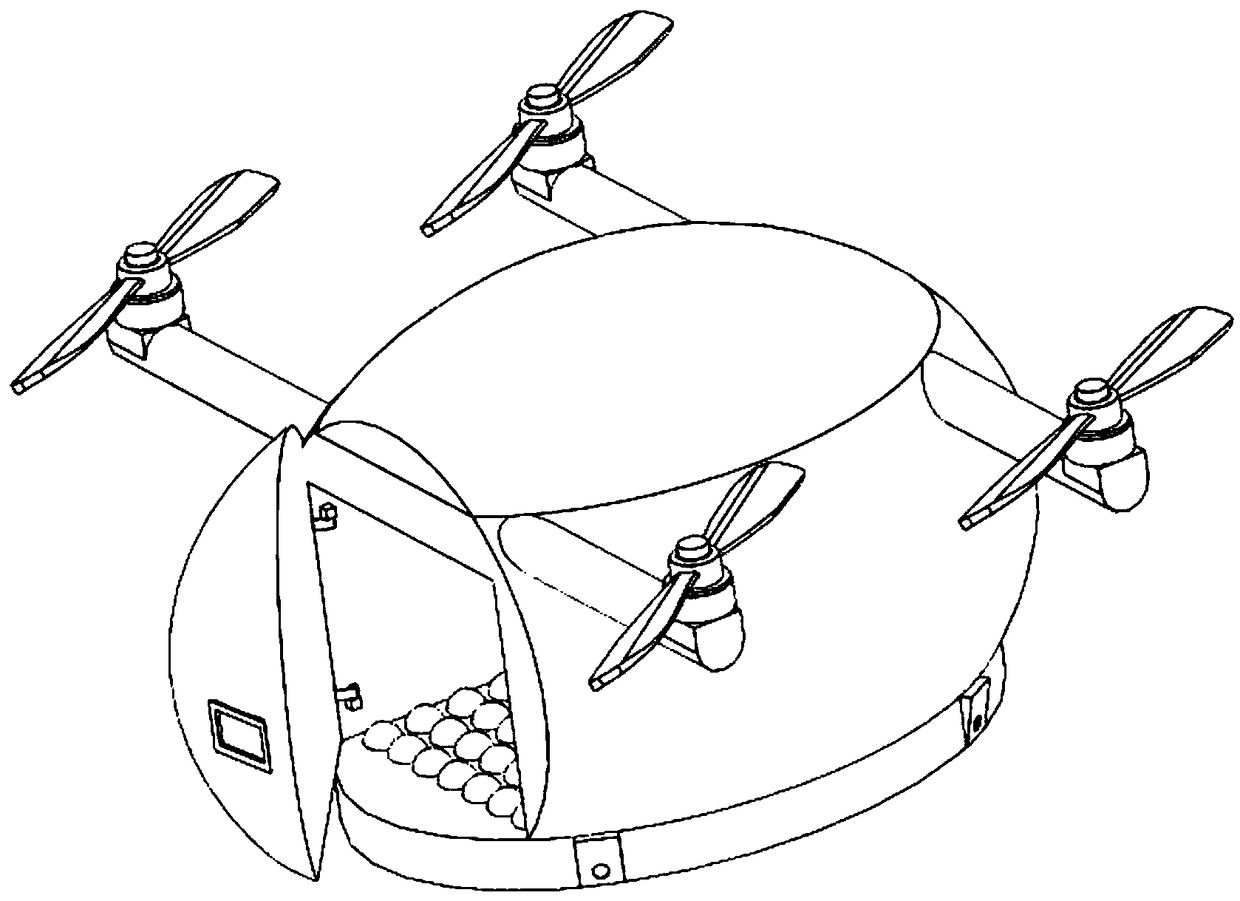

[0030] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. like Figure 1-Figure 3 Shown, a kind of logistics unmanned aerial vehicle comprises fuselage 1, and the top of fuselage is fixed with four machine arms 2, and motor and propeller 3 are installed on each machine arm, and the inside of fuselage is hollow, and the inside of fuselage The bottom is provided with several balls 4, one side of the fuselage is provided with a hatch 5, and the side corresponding to the hatch is provided with an electric push rod 6, and one end of the electric push rod is connected with a push plate 7. It adopts a rectangular parallelepiped inner cavity and pastes the shock-absorbing layer. At the same time, an electric push rod is designed for the clamping function during transportation and the push-out function during unloading. To reduce push-out resistance, light material spher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com