Split type anaerobic ceramic membrane bioreactor capable of relieving membrane pollution effectively

A bioreactor and reactor technology, applied in anaerobic digestion treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problems of serious membrane pollution, high cleaning and renewal costs, etc., and increase shear force. , the effect of increasing the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

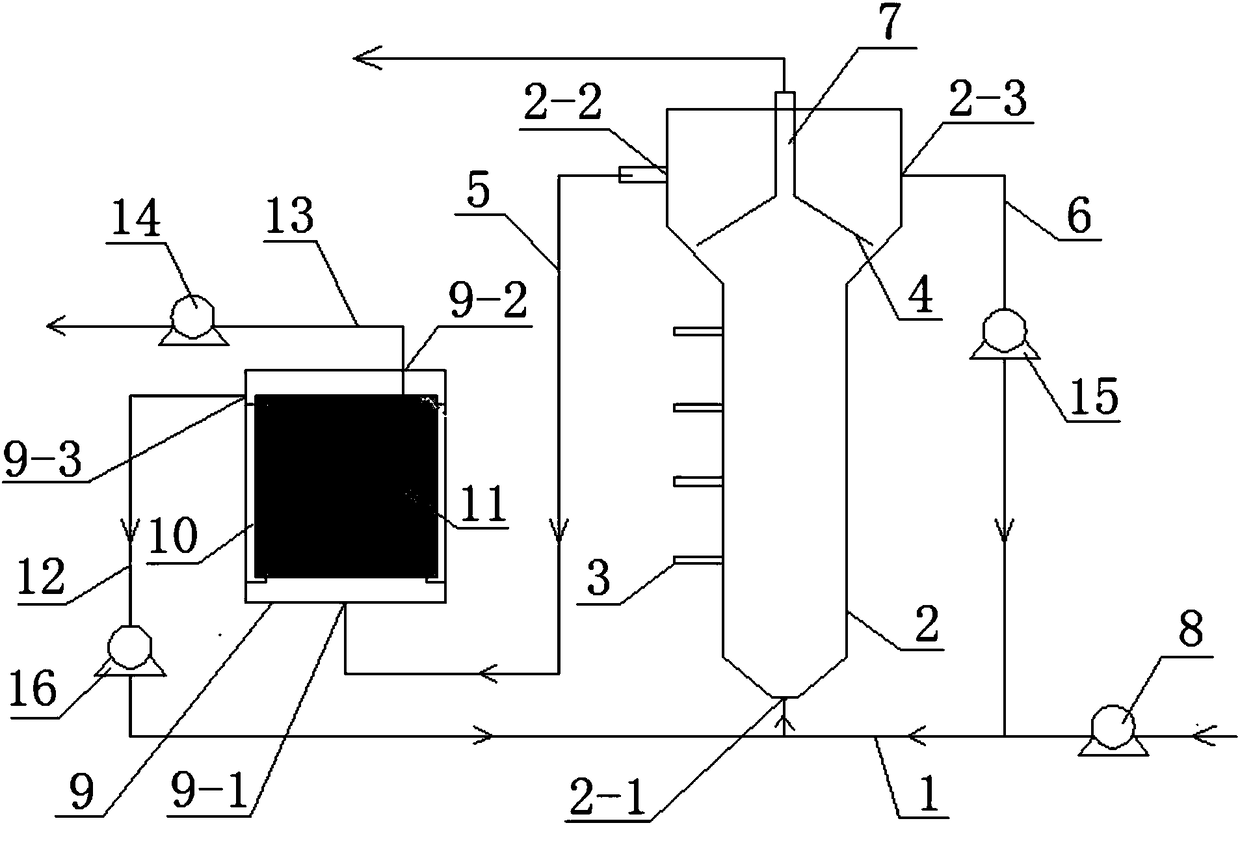

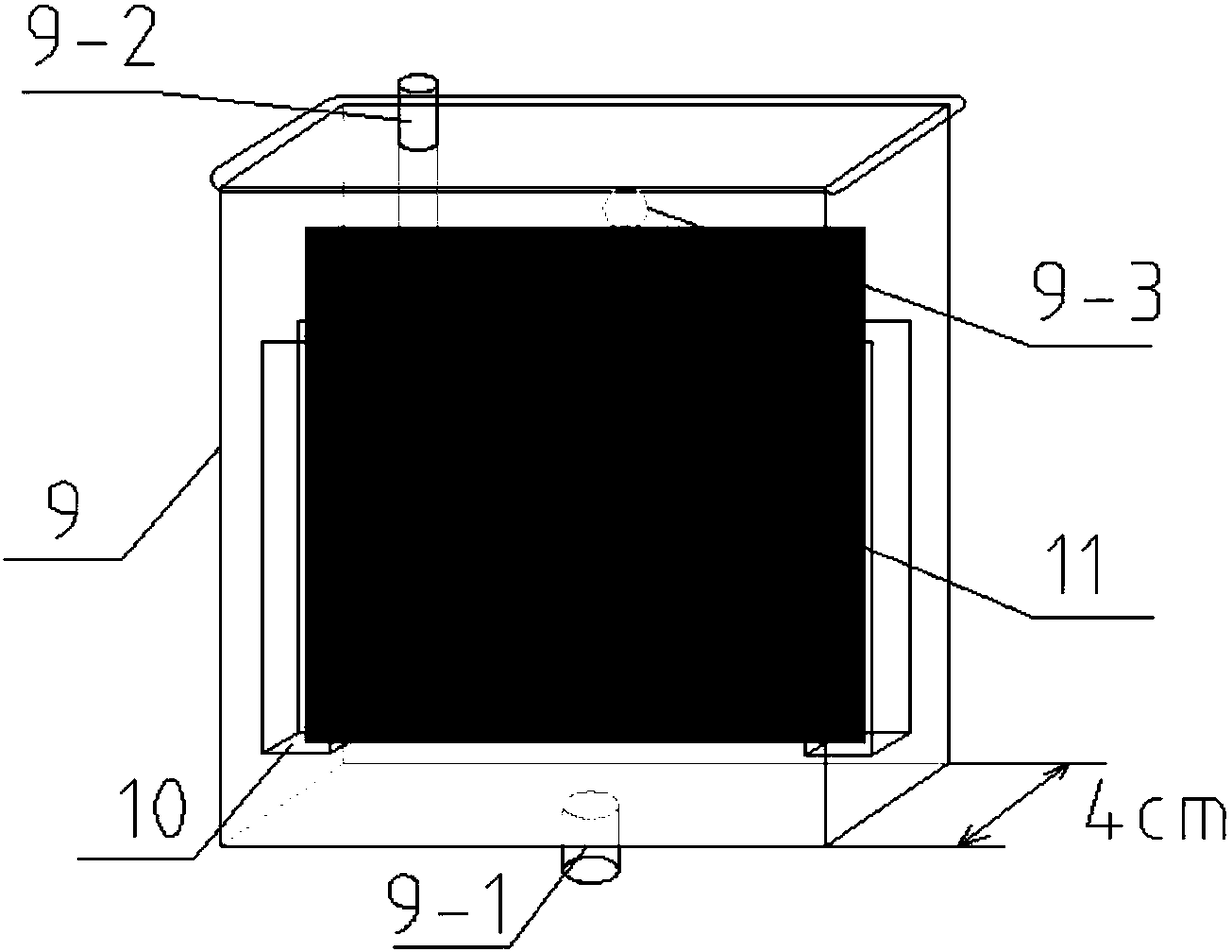

[0017] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment comprises water inlet pipe (1), reactor shell (2), three-phase separator (4), reactor outlet pipe (5), reactor return pipe (6), gas collecting pipe ( 7), water inlet pump (8), membrane group return pipe (12), reactor return peristaltic pump (15), membrane group return peristaltic pump (16) and ceramic membrane module, the bottom of the reactor shell (2) is provided with The reactor water inlet (2-1), the side wall of the reactor shell (2) is provided with a sampling port (3), and the three-phase separator (4) is arranged in the sedimentation area in the reactor shell (2) , one end of the gas collecting pipe (7) is connected with the three-phase separator (4), the other end of the gas collecting pipe (7) is arranged outside the reactor shell (2), and the upper part of the reactor shell (2) is provided with The reactor water outlet (2-2) and the reactor return port (2-3), and the...

specific Embodiment approach 2

[0020] Specific implementation mode two: combination figure 1 Describe this embodiment, this embodiment is that the ceramic diaphragm (11) is a one-piece flat ceramic membrane, and the material is Al 2 o 3 , with a pore size of 0.1 μm. This material has a wider application range and a slower membrane fouling rate than organic membranes such as PVDF used in common anaerobic membrane bioreactors. Other components and connections are the same as those in the first embodiment.

[0021] In this embodiment, the sewage to be treated and the backflow sewage separated by the three-phase separator 4 flow into the reactor from the bottom of the reactor shell 2 through the water inlet pipe 1, and the reaction is made under the joint action of the backflow sewage and anaerobic digestion gas. The anaerobic granular sludge in the zone (the zone inside the reactor shell 2) fully contacts with the sewage to perform anaerobic digestion. After the anaerobic digestion is completed, it is sepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com