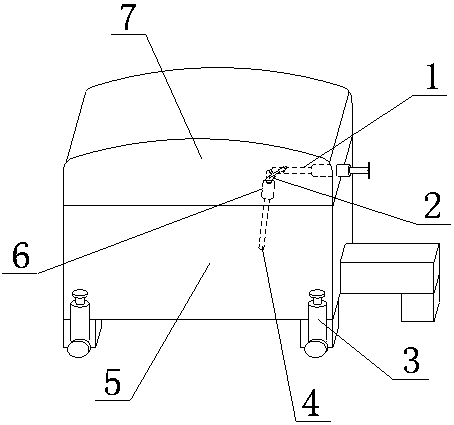

Top insertion powered glass all-electric-smelting kiln

An all-electric melting and kiln technology, which is applied in the direction of electric furnaces, furnaces, furnace types, etc., can solve the problems that the water jacket of the heating electrode cannot be disassembled and replaced, the glass all-electric melting furnace is difficult to move, and the service life of the furnace is shortened. It is easy and fast to disassemble and replace the water jacket, improve the service life of the kiln, and improve the heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

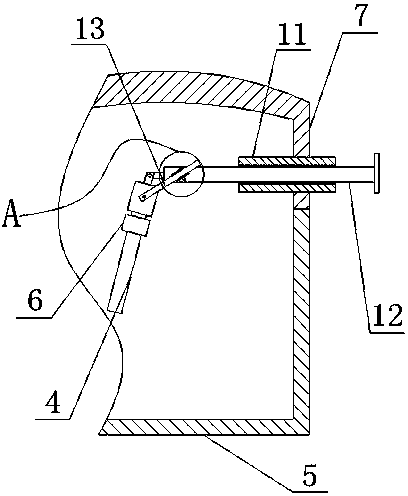

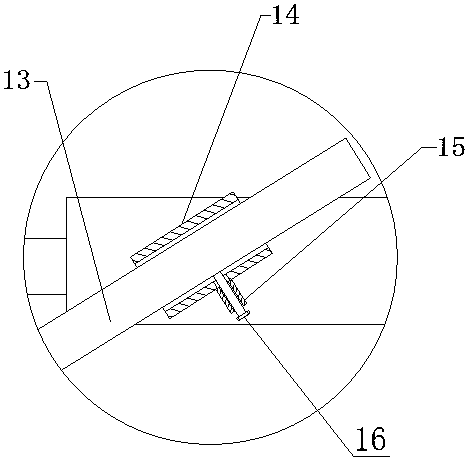

[0028] Specific implementation method: when the heating electrode 4 needs to change the horizontal position, pull the telescopic rod 12, and then the telescopic rod 12 moves horizontally with the fixed chamber 22, the water jacket 6 and the heating electrode 4. When the angle of the heating electrode 4 needs to be changed, hold The fixed cavity 22 rotates the heating electrode 4 to a specified angle, the rotation of the fixed cavity 22 moves the positioning rod 13 in the fixed sleeve 14, tightens the fastening bolt 16, and then the fastening bolt 16 fixes the positioning rod 13 in the fixed sleeve 14 , and then the fixed cavity 22 is fixed, and the heating electrode 4 is fixed at a specified angle. This design achieves the ability to hang the heating electrode 4 in the kiln 5 and adjust the position of the heating electrode 4 according to the actual situation, thereby improving the heating electrode 4. The purpose of heating effect and service life of kiln 5.

[0029] Pull the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com