Preparation method of total-inorganic perovskite quantum dots

A technology of inorganic calcium and quantum dots, which is applied in chemical instruments and methods, nanotechnology, nano-optics, etc., can solve the problem that the ratio of elements cannot be adjusted, achieve high repetition rate, facilitate mass production, and expand sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

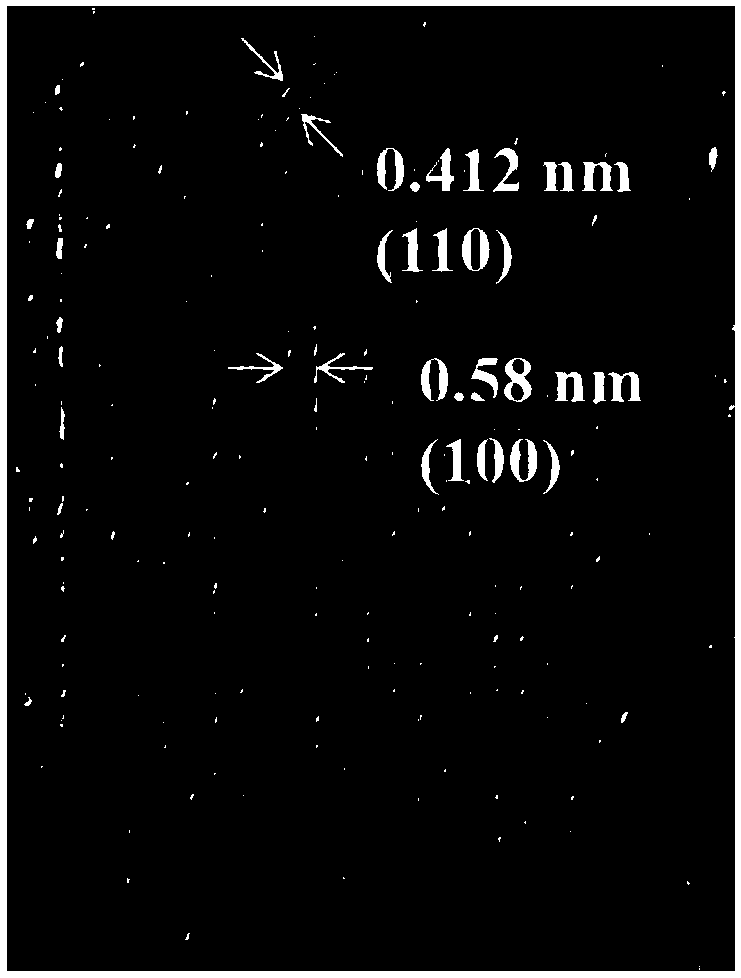

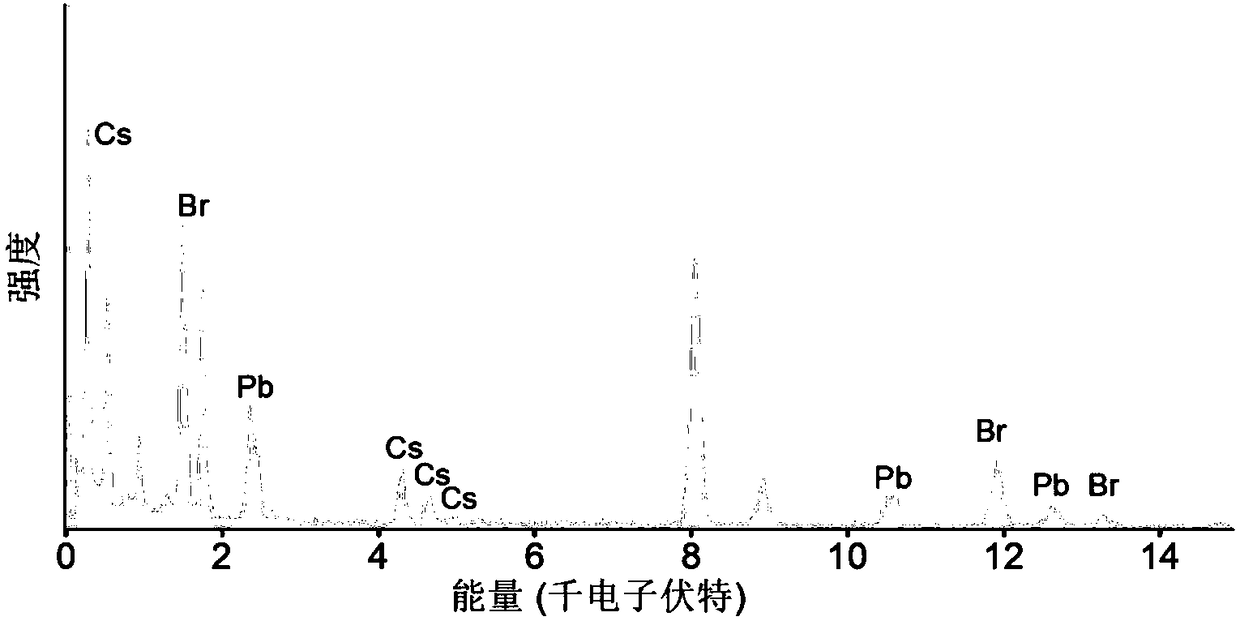

Embodiment 1

[0029] In the first step, the Cs:Pb molar ratio is =1:1.3 cesium source and lead source of the required amount, that is, 0.1g lead stearate and 0.0163g cesium carbonate, are added to the three-necked bottle, dissolved in 10mL of ten Add ligands 0.5mL oleylamine and 0.5mL oleic acid to the octacene, vacuumize and change nitrogen three times at room temperature, the vacuum degree of each vacuum is 0.1kPa, and then turn to the vacuum condition with a vacuum degree of 0.1kPa, Heat to 120°C, maintain for 1h, and dry;

[0030] In the second step, the dried reaction solution obtained in the first step above is changed to nitrogen, and the temperature is raised to 180 ° C, and then 0.04 mL of trimethylbromosilane TMSBr is injected, and after 5 seconds of reaction, the temperature is lowered in an ice-water bath. stop responding;

[0031] In the third step, add 5 mL of precipitating agent ethyl acetate to the reaction liquid obtained in the above second step, centrifuge with a centrif...

Embodiment 2

[0038] Except that in the first step, the lead source lead stearate used is changed into lead nitrate, and quality is 0.043g, other is with embodiment 1.

Embodiment 3

[0040] Except that in the second step, the dried reaction solution obtained in the above first step was changed to nitrogen condition, and the temperature was raised to 140° C., the others were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Shine | aaaaa | aaaaa |

| Half width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com