Textile pre-treatment solution as well as preparation technology and application thereof

A pretreatment liquid and textile technology, applied in the field of paint ink printing, can solve the problems of poor color brilliance, low wet rubbing fastness, low color yield of paint ink printing, etc., to achieve good color expression, without affecting the hand feeling, Effect of improving color yield and vividness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

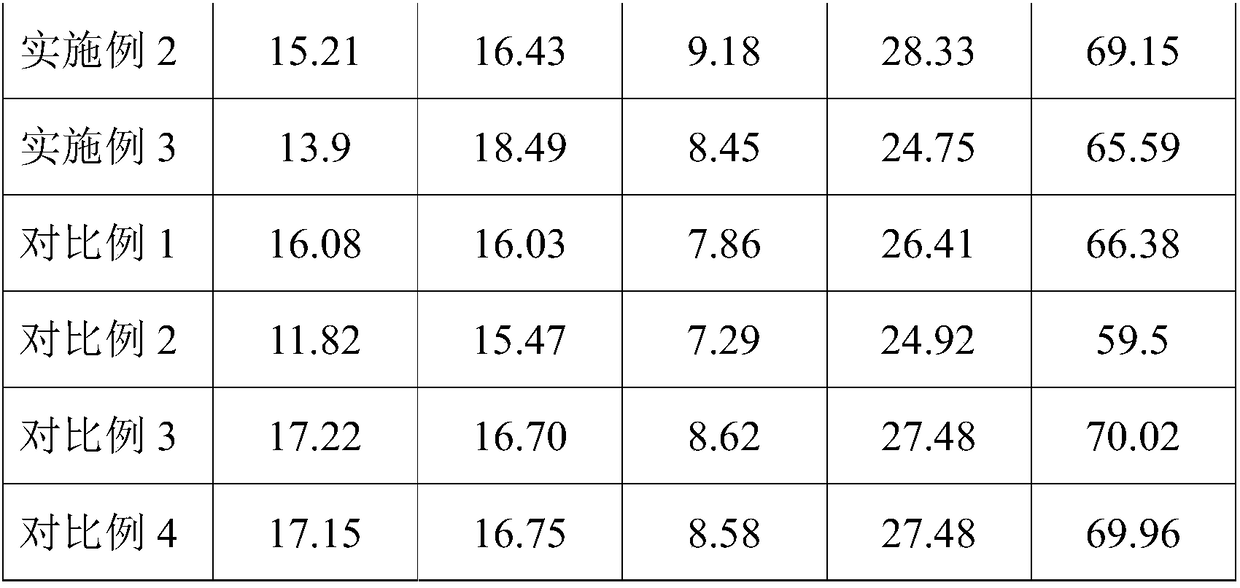

Examples

Embodiment 1

[0025] Weigh by mass: 10 parts by mass of cationic modifier LD-8202, 0.2 parts by mass of acid-base regulator triethanolamine, 0.5 parts by mass of surfactant Surfynol 465, 10 parts by mass of co-solvent isopropanol, 3 parts by mass of cationic waterborne polyurethane Dispersion CW-1001 and 76.3 parts by mass of deionized water. The above materials are stirred at a stirring speed of 300-500 rpm for 10-30 minutes, and mixed evenly to obtain a textile pretreatment liquid.

Embodiment 2

[0027] Weighing by mass: 8 parts by mass of cationic modifier Hansi GRE, 1 part by mass of acid-base regulator citric acid, 1 part by mass of surfactant Surfynol 485, 5 parts by mass of cosolvent ethanol, 5 parts by mass of cationic polyurethane resin IMK880 and 80 parts by mass of deionized water. The above materials are stirred at a stirring speed of 300-500 rpm for 10-30 minutes, and mixed evenly to obtain a textile pretreatment liquid.

Embodiment 3

[0029] Weighing by mass: 12 parts by mass of cationic modifier Rebacath NT-2A, 1 part by mass of acid-base regulator citric acid, 1 part by mass of surfactant Surfynol 485, 10 parts by mass of cosolvent ethanol, 5 parts by mass of cationic water-based polyurethane dispersion Body CW-1001 and 71 parts by mass deionized water. The above materials are stirred at a stirring speed of 300-500 rpm for 10-30 minutes, and mixed evenly to obtain a textile pretreatment liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com