Five anti-oil pipes and short connections

A technology for tubing and shorting, which is applied in the direction of drill pipe, casing, drill pipe, etc., and can solve the problems of high complexity of downhole tools, failure of tubing couplings to prevent buckling, and obstacles to the design direction of downhole tools. Broaden design ideas, excellent anti-wear performance, and prevent buckling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

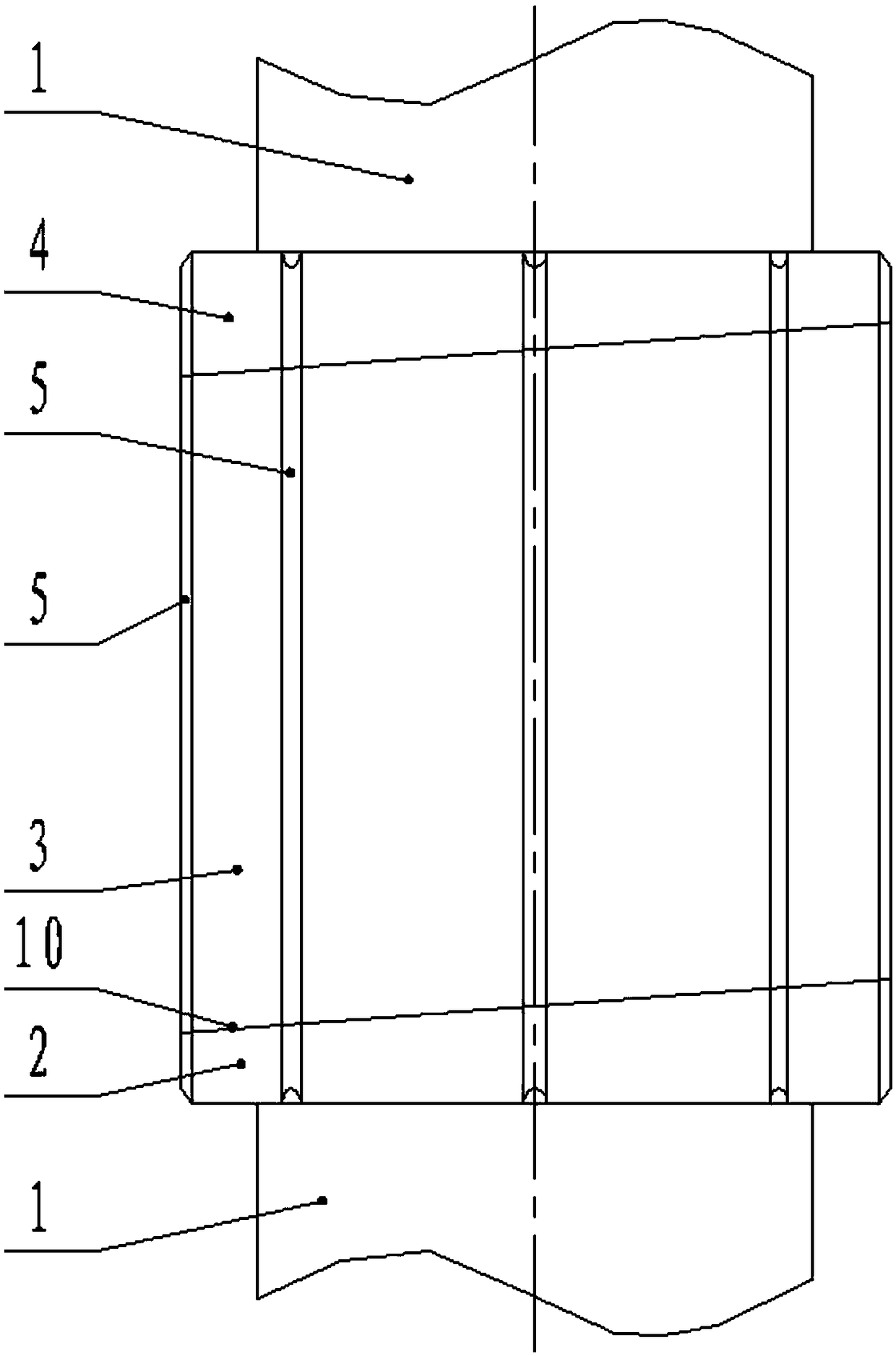

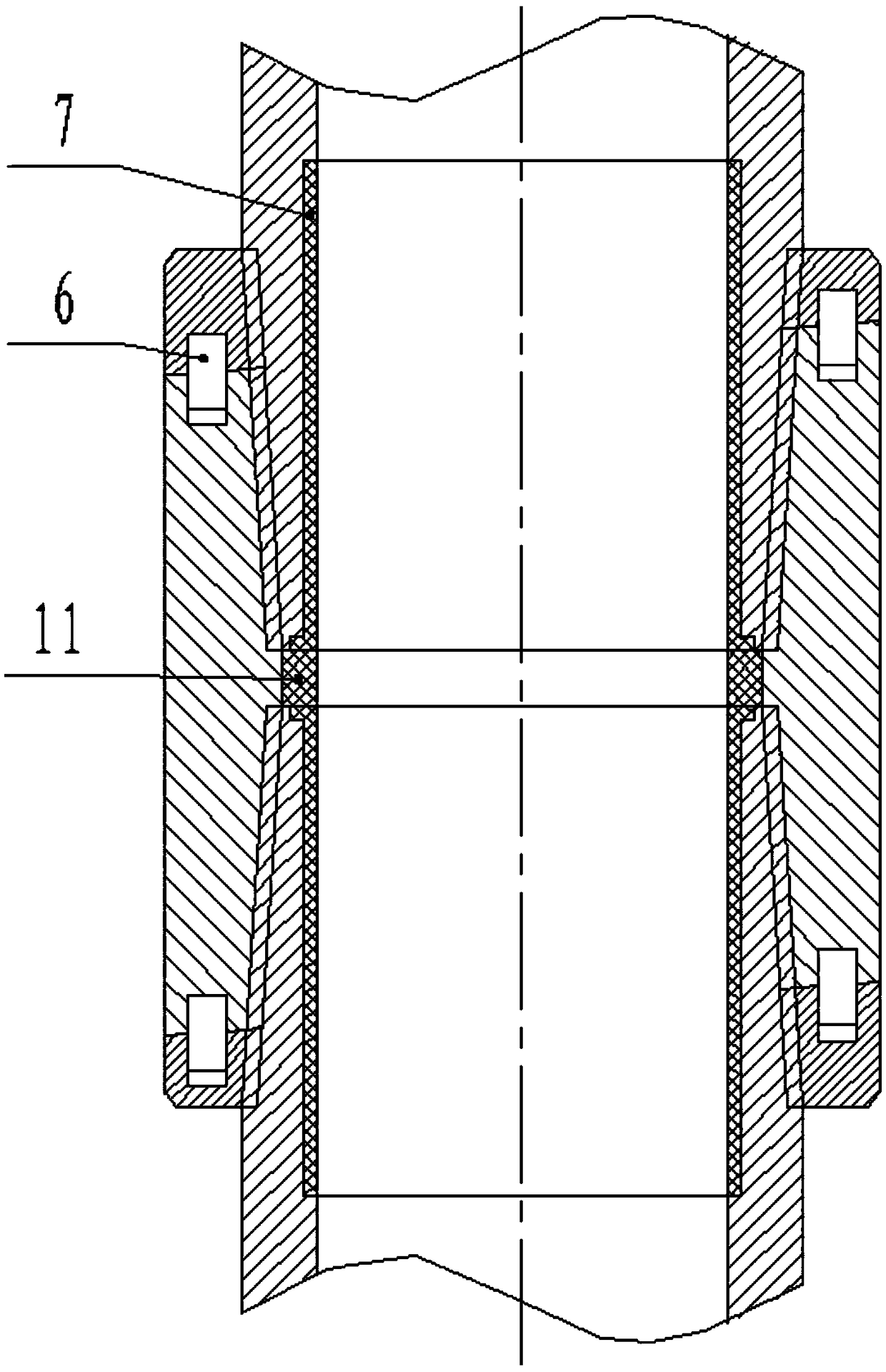

[0021] The present invention will be further described below in conjunction with accompanying drawing:

[0022] The invention includes an oil pipe body 1 and a collar, which are connected through an oil pipe thread. The above is the conventional structure of the oil pipe, which will not be repeated here.

[0023] The inside of the end of the oil pipe body 1 is provided with a composite wear-resistant layer 7 , and the inner diameter of the composite wear-resistant layer 7 is the same as that of the oil pipe body 1 . The arrangement of the composite wear-resistant layer 7 can effectively improve the local wear resistance of the end of the oil pipe body 1 , thereby improving the service life of the oil pipe body 1 . In addition, compared with the wear-resistant treatment of the entire section of the inner wall of the oil pipe body 1 in the prior art, the present invention only performs wear-resistant treatment on the end of the oil pipe body 1, greatly reducing the difficulty o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com