Particulate loading amount calculating method for particulate filter and device thereof

A particle trap, particle technology, used in computing, mufflers, exhaust devices, etc., to solve problems such as changes, heavy work, and inaccurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

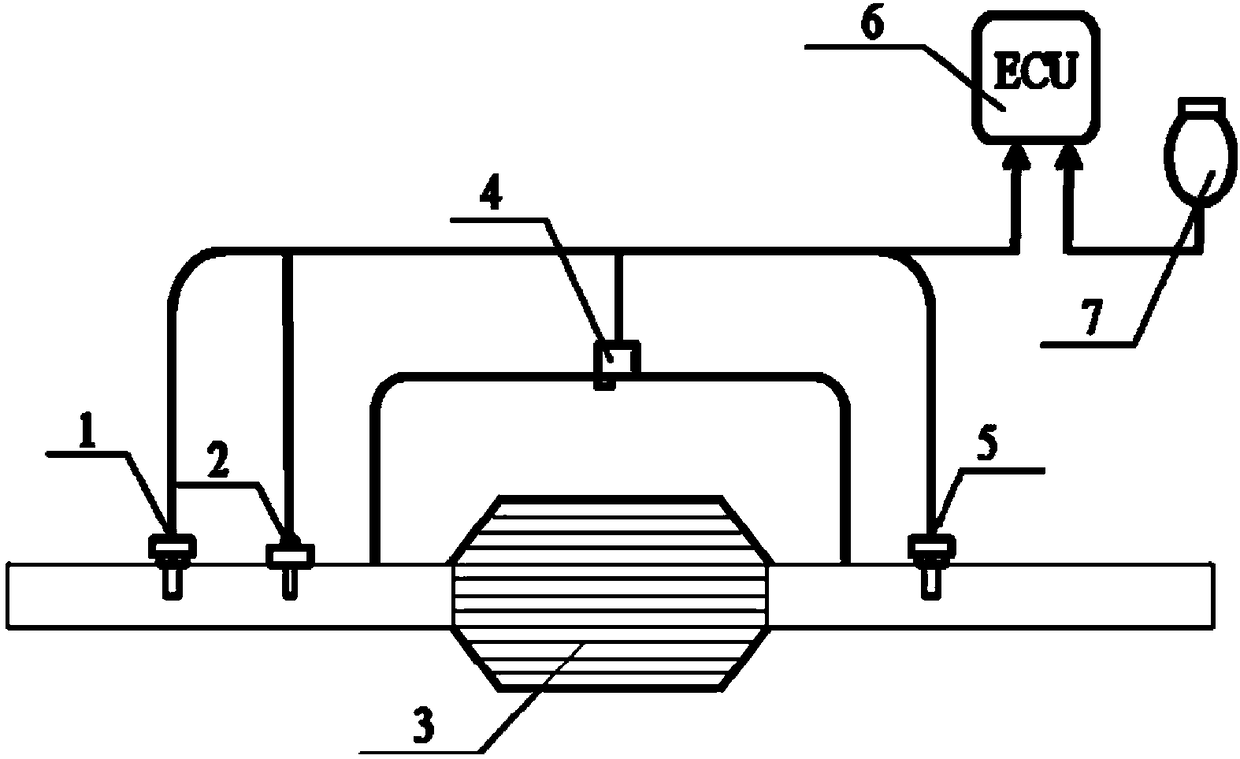

[0024] Such as figure 1 As shown, the hardware device of the calculation method includes a temperature sensor 1 for monitoring the temperature signal at the front end of the particle trap. Oxygen sensor 2 is used to correct the air mass flow rate and fuel consumption rate. Particle trap 3, as a carrier for particle deposition. The differential pressure sensor 4 transmits the differential pressure signal at both ends of the particle trap to the ECU. The temperature sensor 5 is used to correct the temperature at the front end of the particle trap. ECU6 is used to receive and process signals such as temperature, differential pressure, oxygen concentration, fuel consumption rate, and air mass flow. The air mass flow meter 7 monitors the intake air quality signal of the engine intake pipe and transmits it to the ECU.

[0025] In this calculation method, the ECU records the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com