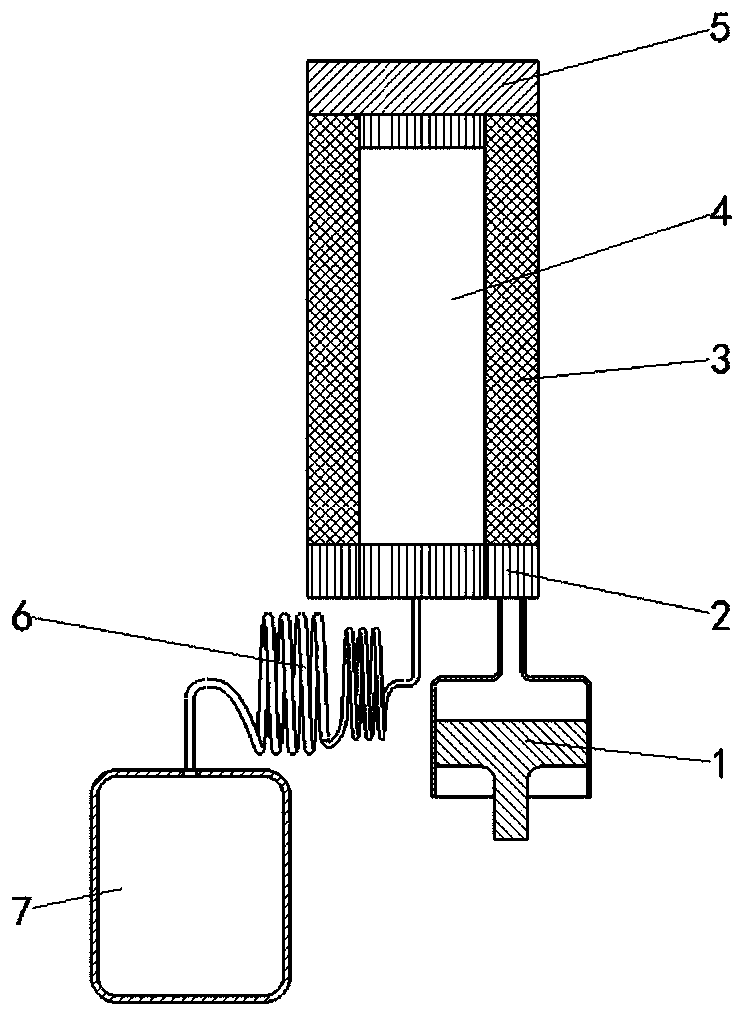

Manufacturing method of split welded hot end heat exchanger of coaxial pulse tube refrigerator

A technology of pulse tube refrigerator and heat exchanger, which is used in the manufacture of split-welded hot end heat exchangers, and the field of pulse tube refrigerators, can solve the destructive effects of non-metallic O-rings and bolts. It can reduce the number of leak detection fixtures, improve the service life and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

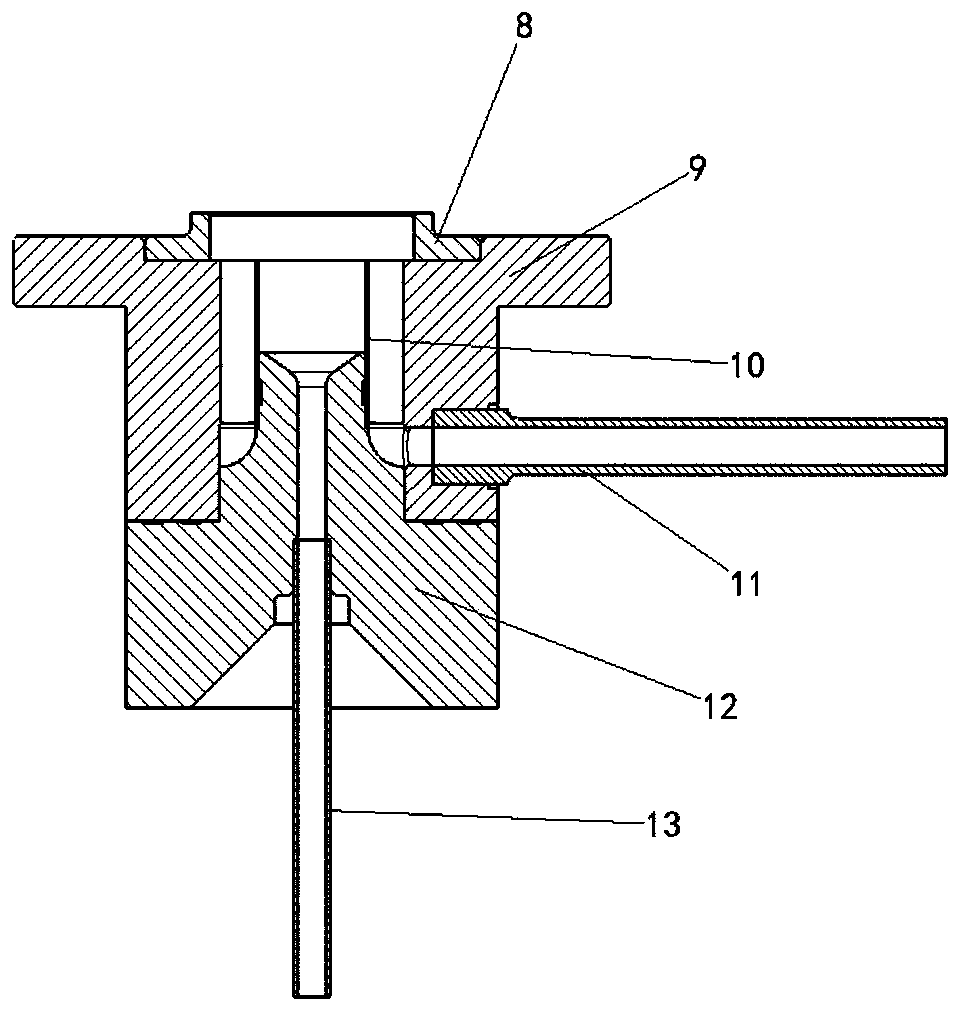

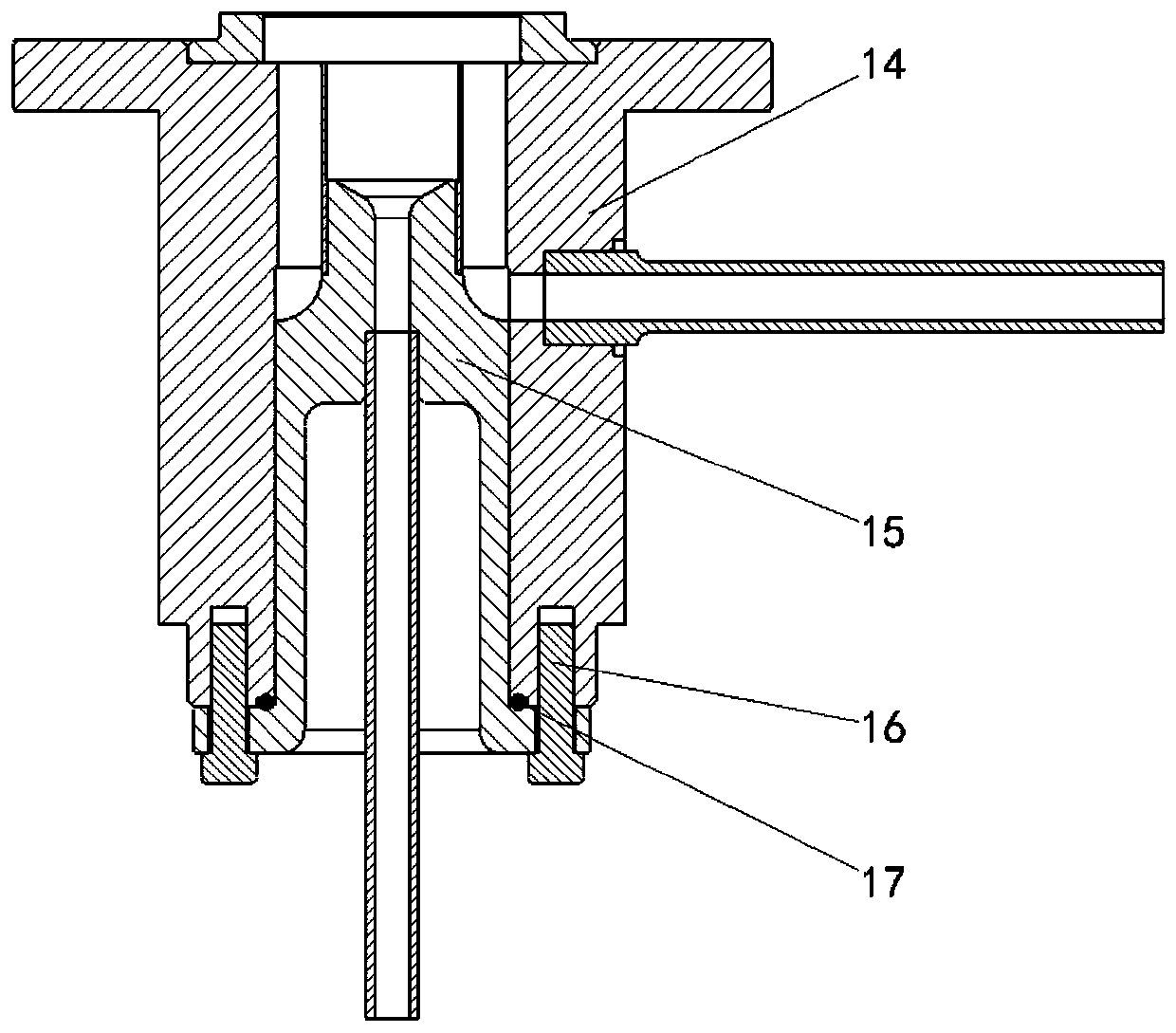

[0022] The specific implementation of the present invention will be further described in detail below with reference to the drawings and embodiments.

[0023] The manufacturing method of the split welded hot end heat exchanger of the invented coaxial pulse tube refrigerator is as follows:

[0024] The cold finger seat 8, the split heat exchanger 9 and the split pulse tube seat 12 are all made of metal materials with high thermal conductivity. First, use an ordinary lathe to process the three blanks, and then anneal to remove internal stress and perform aging After processing, use a precision lathe for finishing; in the lathe processing procedure, the slit inner hole 26 of the split heat exchanger is processed in place; then the interior of the split heat exchanger 9 is processed by a slow-moving wire high-precision wire cutting machine The annular slit 27 of the split heat exchanger, the width of the slit is 0.1mm, and the number of slits is 80; the drill is processed on the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com