Double-layer nanometer optical grating-based micro-nano gyroscope and processing method thereof

A nano-grating and gyroscope technology, applied in the micro-opto-electromechanical and inertial navigation fields, can solve problems such as difficulty in balancing accuracy and dynamic performance, capacitance detection is easily interfered by parasitic effects, and limits the application of micro-electromechanical gyroscopes, etc., achieving good market prospects , small mass, free from electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

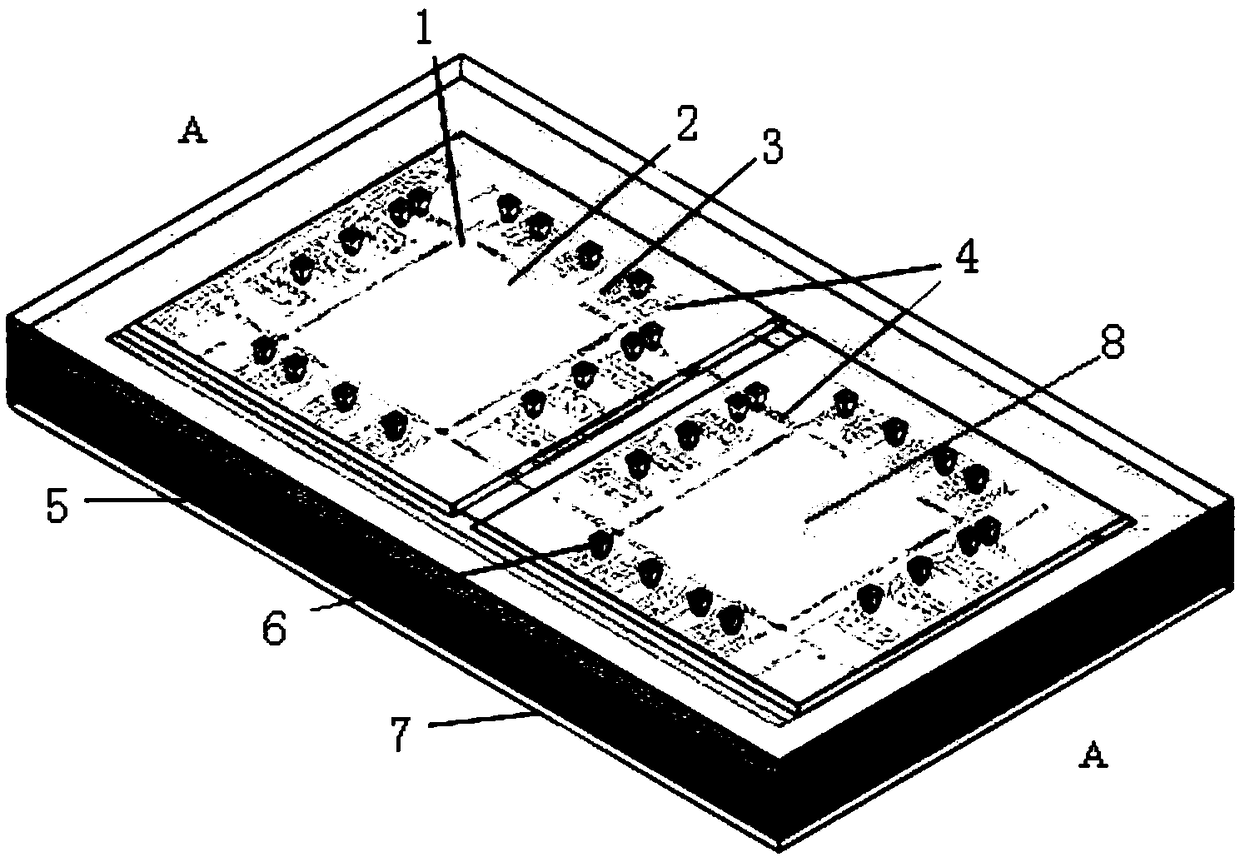

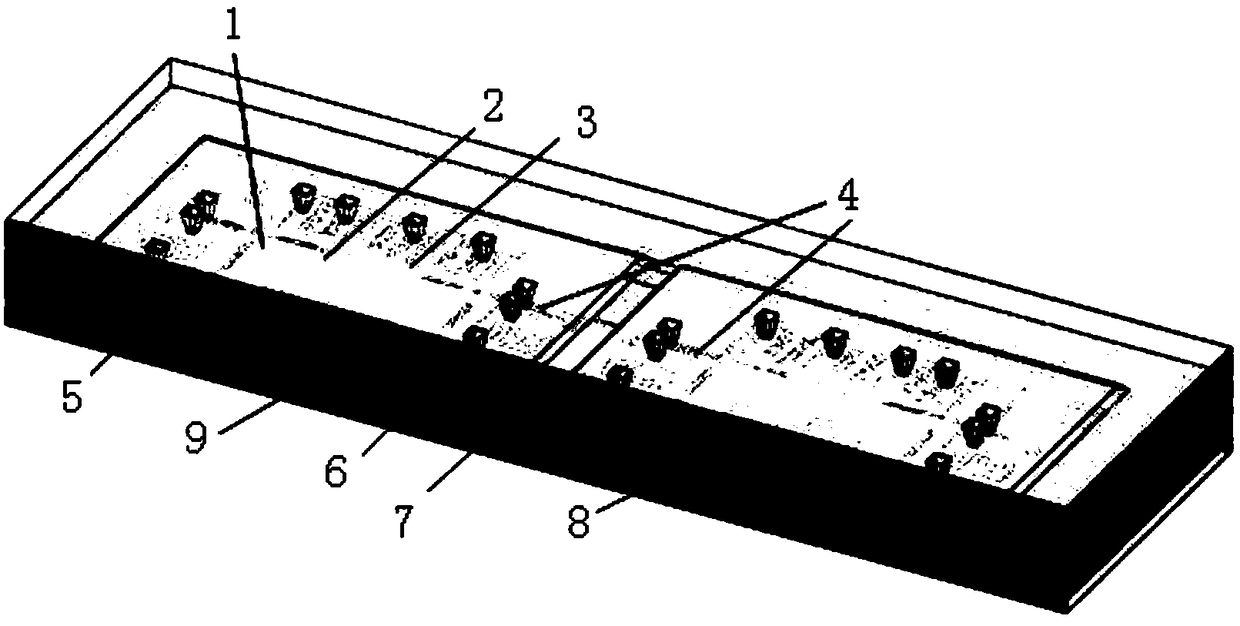

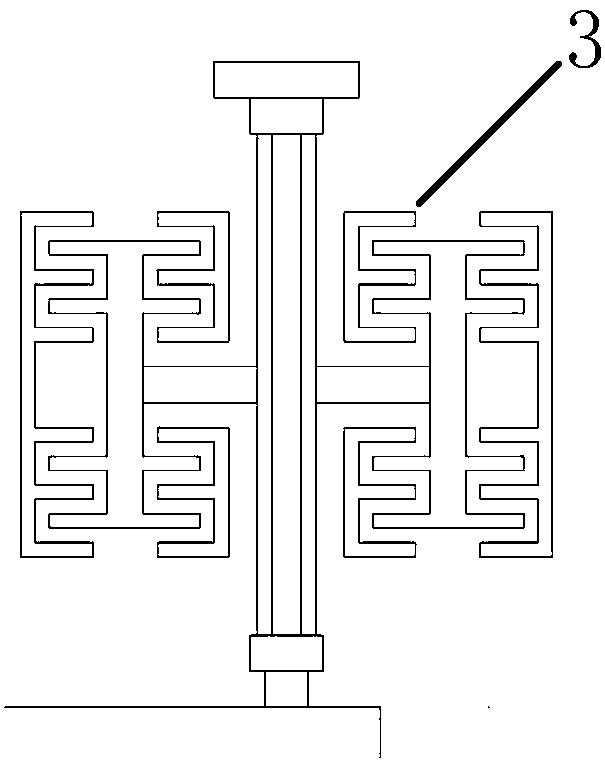

[0037] Such as Figure 1-4As shown, a micro-nano gyroscope based on a double-layer nano-grating includes a glass substrate 7, a support structure, a double-mass microresonator 1 and a glass cap 5. The support structure is a topless box structure, and the glass lining The bottom 7, the support structure and the glass cap 5 are sequentially connected from bottom to top to form a cavity structure, and the double-mass microresonator 1 is arranged in the support structure; the double-mass microresonator 1 includes two groups of symmetrically arranged microresonators, each The set of microresonators includes a mass block 2, a driving frame 3, a decoupling beam 4 and a movable grating 8, the movable grating 8 is set at the center of the mass block 2, the driving frame 3 is set around the mass block 2, and the decoupling beam 4 is set at the center of the mass block 2. At the four corners of the mass block 2, they are respectively connected to the drive frame 3 on two adjacent sides; ...

Embodiment 2

[0053] It is basically the same as Embodiment 1, the difference is: in step 2), electron beam exposure is adopted to directly obtain the pattern and position; the device pattern can be processed together with the movable grating 8 pattern, reducing processing steps and reducing alignment errors.

[0054] The technologies not mentioned in the present invention refer to the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com