Intelligent coal yard control system of thermal power plant and it control method

A thermal power plant, management and control system technology, applied in the direction of electrical program control, general control system, control/regulation system, etc., can solve the problem that the automatic unattended control of the stacker and reclaimer cannot be realized, and the specific method of coal yard management has not been designed and methods, the inability to realize intelligent coal yard management and control of circular coal yards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

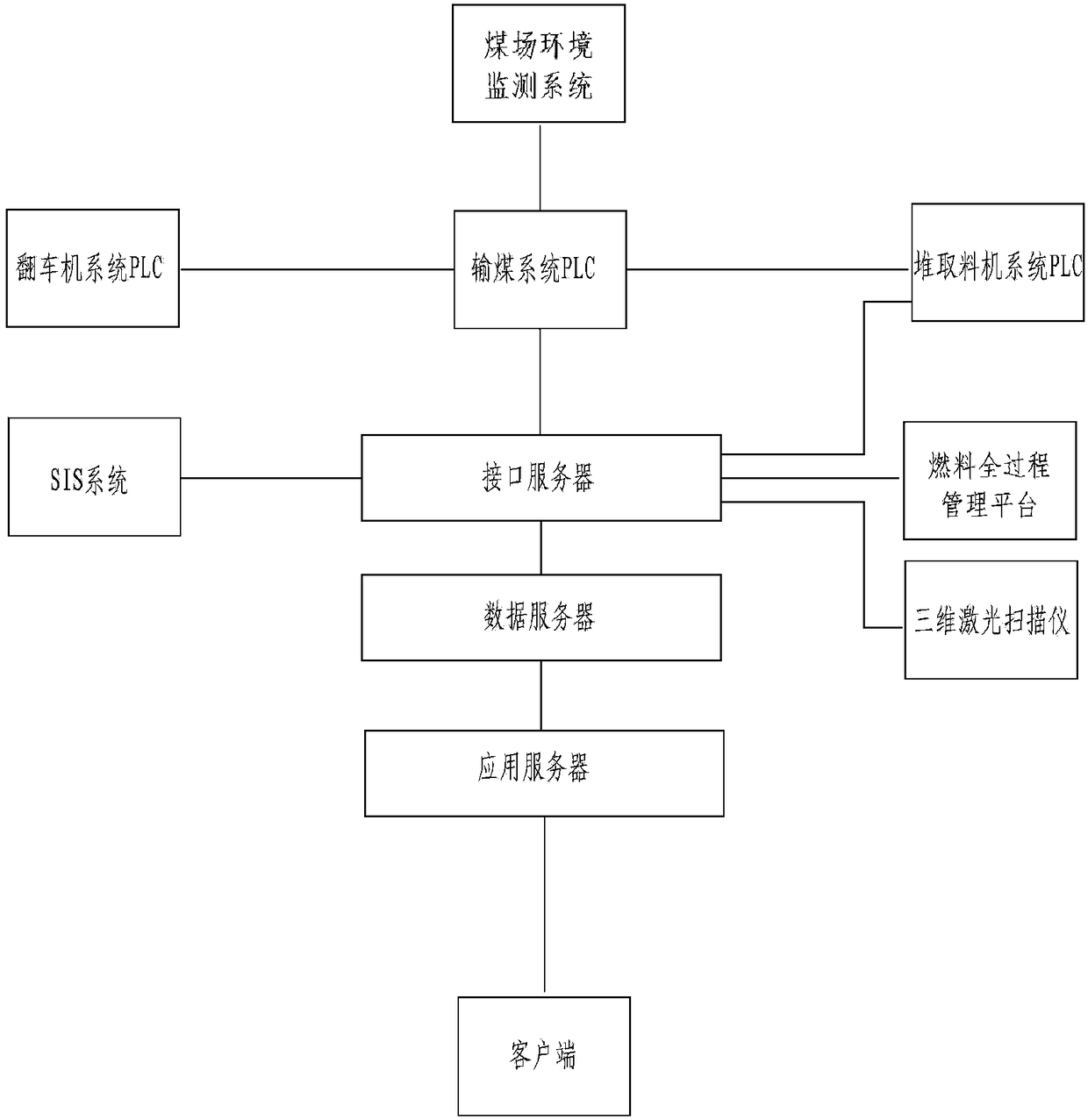

[0043] Attached below figure 1 To further explain the present invention:

[0044] An intelligent coal yard management and control system for thermal power plants. The data server is connected to the application server and the interface server, the data server is connected to the application server and the interface server, the application server is connected to the client, and the interface server is connected to the coal conveying system PLC, SIS system, and the entire process of fuel A management platform, a three-dimensional laser scanner, and a stacker and reclaimer system PLC, the coal conveying system PLC is connected to the car dumper system PLC, the coal yard environmental monitoring system, and the stacker and reclaimer system PLC. The application server, the data server, the interface server, and the client realize data communication through industrial-grade switches, the coal handling system and its control system, the stacker and reclaimer system and its control syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com