Microwave ablation needle with antenna assembly

A microwave ablation and antenna assembly technology, applied in the field of medical equipment, can solve the problems of the choke ring suppressing the performance of surface current, the radiation performance of the monopole antenna, and the unclear development of zirconia ceramics, etc., so as to facilitate clinical treatment and improve the Bandwidth, effect of mitigation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

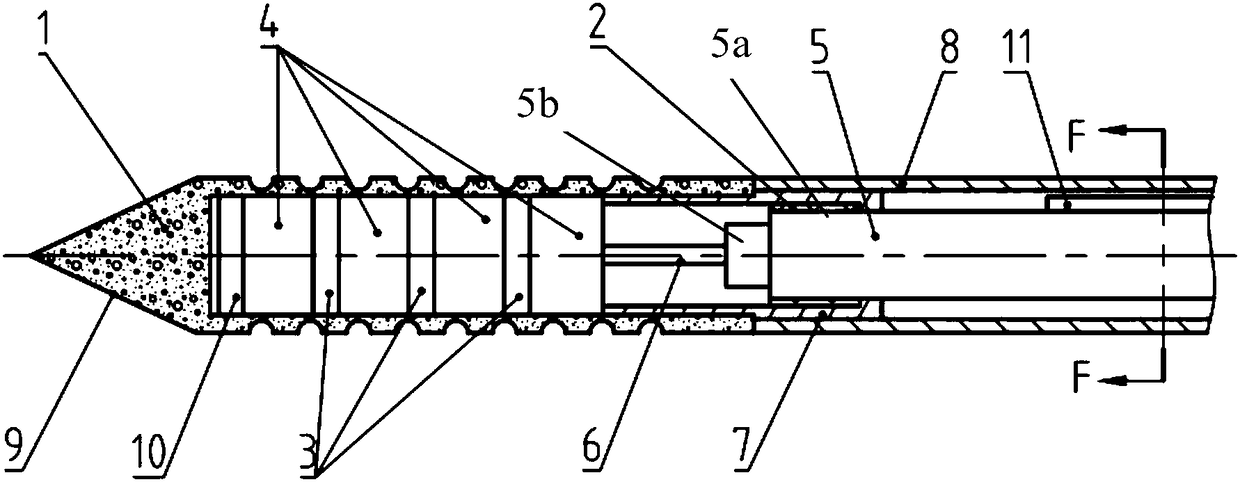

[0046] Such as figure 1 , a microwave ablation needle with an antenna assembly provided in this embodiment, including a radiator and a needle bar 8 connected to the radiator, the radiator includes a needle head 1, a high temperature resistant insulating medium 2, a quasi-fractal part 3, and a medium loading part 4 , microwave cable 5, cable inner core 6, sleeve 7, needle bar 8, anti-stick coating 9, top loading part 10 and cooling channel 11, top loading part 10, quasi-fractal part 3, medium loading part 4 and microwave cable The inner core 6 of the cable 5 is electrically connected, and the sleeve 7 is electrically connected to the outer shielding layer of the microwave cable 5; Connect, use high-temperature ceramic glue for bonding, the glue can be high-temperature resistant epoxy glue, or inorganic high-temperature resistant glue, and the temperature resistance requirement should be above 200 °C. The cable includes a cable shielding layer 5a, an insulating medium layer 5b,...

Embodiment 2

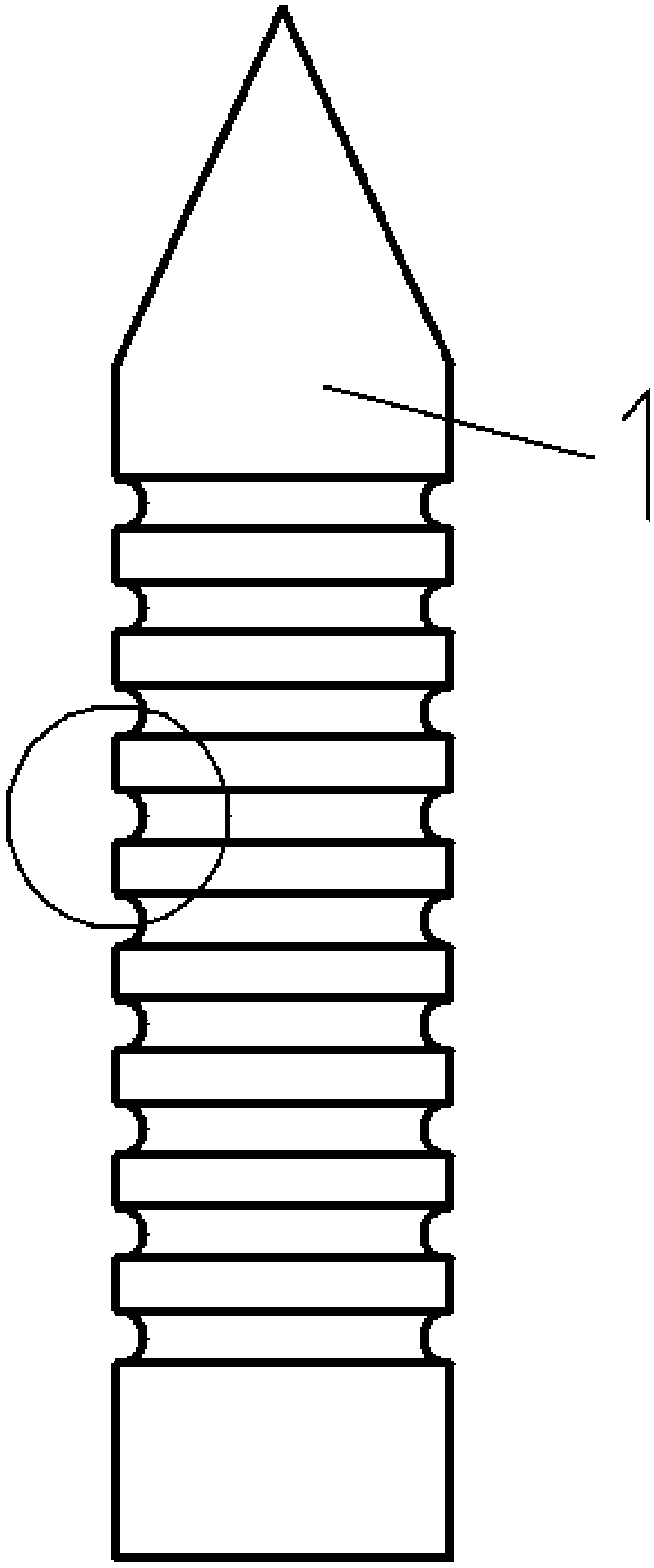

[0068] The outer surface of the needle 1 can be machined and powder injection molded to process a semicircular groove with a radius of 0.01 mm to 0.1 mm in depth on the surface of the needle 1. The depth of the groove is related to the frequency and wavelength of the ultrasonic probe. The depth can be adjusted according to clinical application.

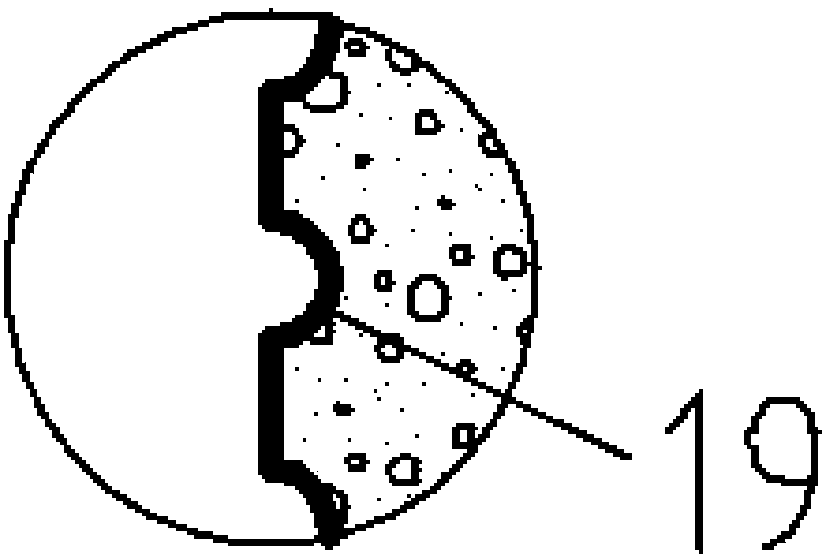

[0069] Such as Figure 2a and 2b , There is more than one groove 19 on the outside of the needle head 1, and the shape of the notch is a semicircular groove.

Embodiment 3

[0071] The outer surface of needle 1 can be processed by powder injection molding process, and the radius of 0.01mm~0.1mm can be processed on the surface of needle 1. Triangular grooves, triangular grooves are used to change the direction of ultrasonic reflection, and the depth of each triangular groove can be inconsistent. Adjust the size of the triangle angle, change the direction of ultrasonic reflection, reduce scattered ultrasonic waves, and increase the proportion of returned ultrasonic probe waves, thereby improving the effect of ultrasonic imaging.

[0072] Such as Figure 3a and 3b , the needle 1 is provided with more than one groove 20, and the shape of the notch is triangular.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com