Battery cell, electronic equipment and battery cell package method

A technology of batteries and batteries, which is applied in the field of batteries, can solve problems such as the size cannot be made large enough, the failure of batteries, the deformation of winding cores, etc., and achieve the effects of not easy to deform and fail, safe and reliable in use, and good in structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

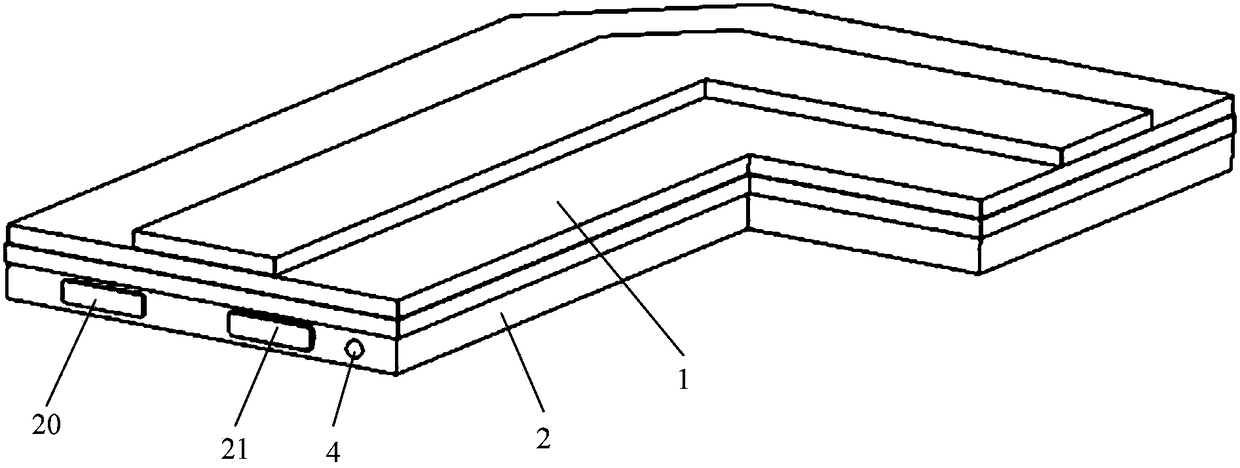

[0047] Such as figure 1 As shown, this embodiment provides a battery cell, including: a casing and a battery cell.

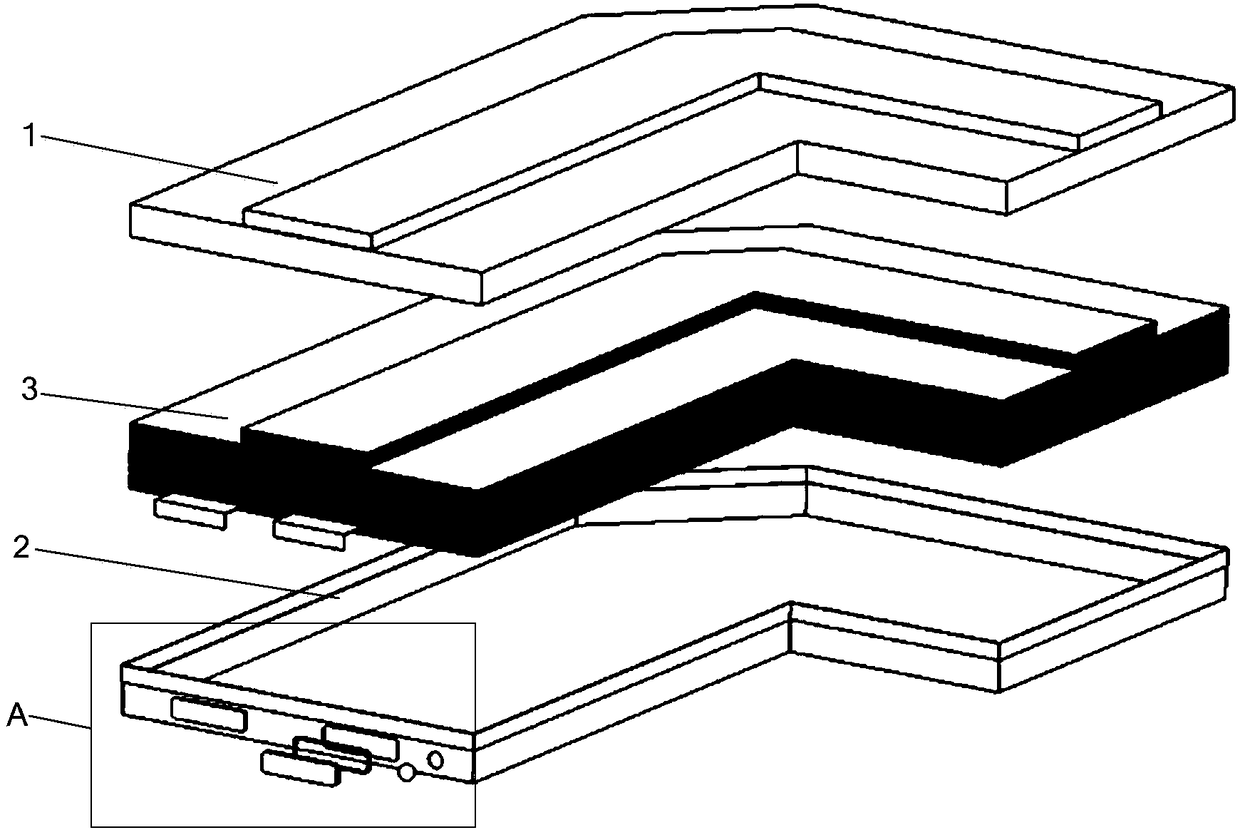

[0048] Among them, such as figure 2 As shown, the housing includes a steel lower shell 2 and a steel upper shell 1. Due to the good rigidity of the steel material, it is easy to form, so that the upper shell 1 and the lower shell 2 can be made into various sizes and shapes ( Such as special-shaped shape), so that the shell can be in various shapes, so as to be able to adapt to the design requirements of electronic devices such as mobile phones or wearable devices.

[0049] In addition, due to the weldability of the steel material, the lower shell 2 and the upper shell 1 can be connected by welding, realizing the sealed connection between the upper shell 1 and the lower shell 2, and forming a seal between the upper shell 1 and the lower shell 2 cavity, so that the battery cell is hermetically fixed in the sealed cavity of the case.

[0050]In addition, becaus...

Embodiment 2

[0069] This embodiment provides an electronic device (not shown), including: a device body with a battery compartment and the battery cell described in Embodiment 1, and the battery cell is installed in the battery compartment.

[0070] The electronic device of this embodiment includes the electric cell described in the first embodiment, and thus also has all the beneficial effects of the electric cell described in the first embodiment.

[0071] Since the shell of the battery cell is a steel shell with good strength, the battery cell can not only be fixed in the battery compartment by bonding, but also can be fixed in the battery compartment by clamping, for example: it can be fixed in the battery compartment Buckles and buckles are respectively set on the battery compartment and the buckle, and the batteries are fixed in the battery compartment through the buckle and the buckle, and the fastened and fixed batteries are easy to disassemble and easy to replace and recycle. Reus...

Embodiment 3

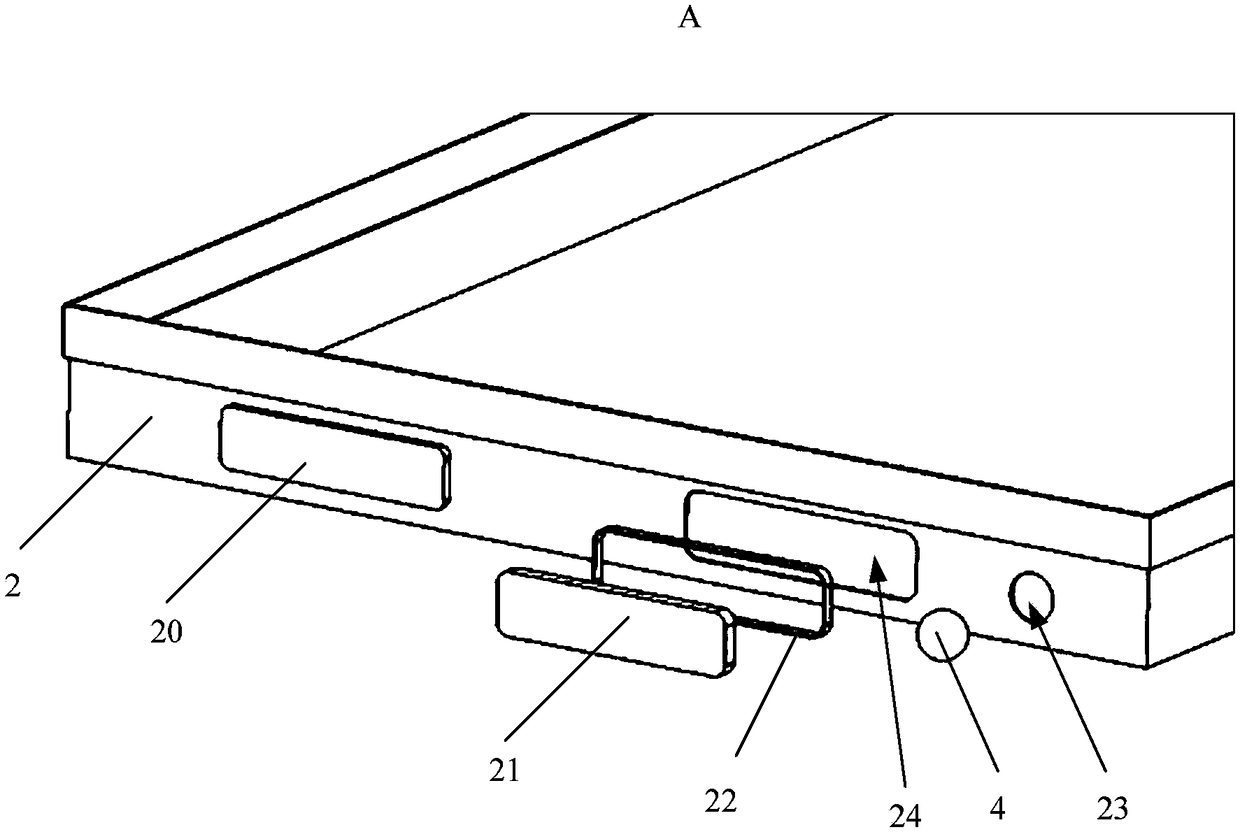

[0075] This embodiment provides a battery packaging method, wherein the battery includes a shell and a laminated battery core, the shell includes a steel lower shell and a steel upper shell, and the upper shell and the lower shell are provided on the surface. There is an insulating layer, the lower case is provided with a positive electrode contact piece and a negative electrode contact piece, and the upper case or the lower case is provided with a liquid injection hole.

[0076] The packaging method of the electric core comprises the following steps:

[0077] S1: Put the laminated battery cell 3 into the lower case 2;

[0078] S2: welding the positive tab 33 of the laminated battery to the positive contact 20 of the lower case 2, and welding the negative tab 34 of the laminated battery to the negative contact 21 of the lower case 2;

[0079] S3: Fasten the upper shell 1 to the lower shell 2, and seal and weld the surroundings of the upper shell 1 and the lower shell 2;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com