A medical plastic syringe recycling device

A recovery device and medical technology, applied in the field of disinfection and recovery devices, can solve the problems of slow speed, a large number of human resources, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

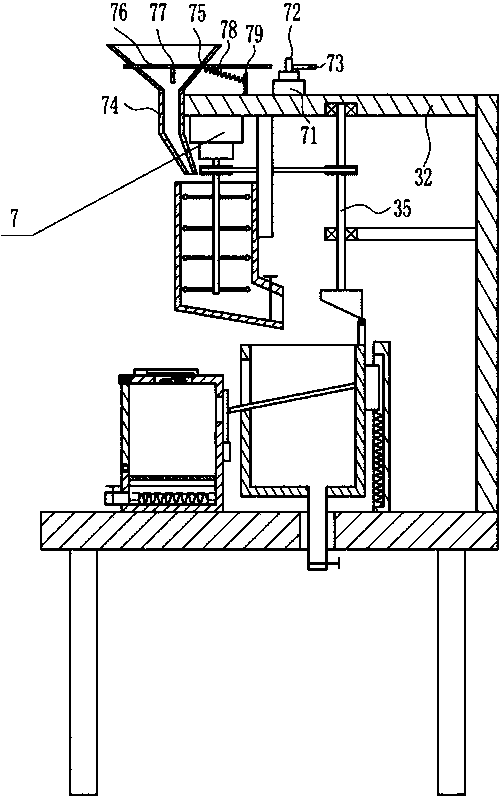

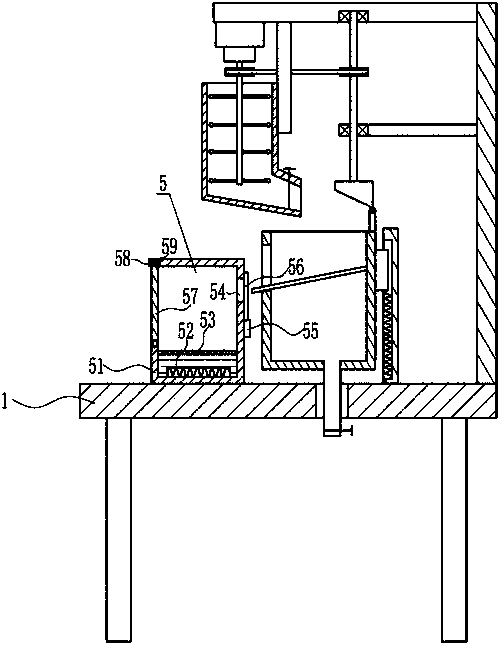

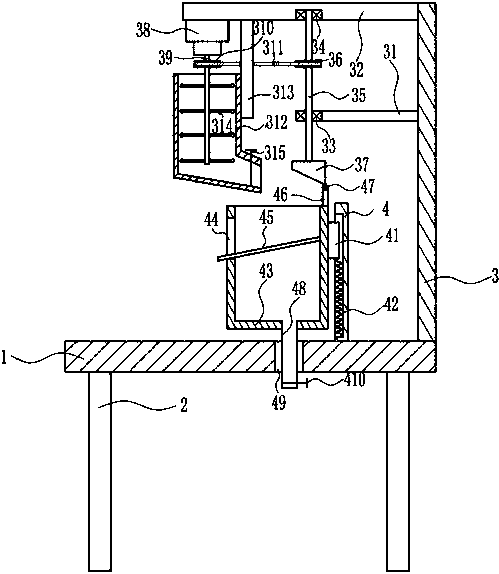

[0029] A medical plastic syringe recycling device, such as Figure 1-5 Shown, include bottom plate 1, supporting foot 2, first bracket 3, first pole 31, second bracket 32, first bearing 33, second bearing 34, rotating shaft 35, first pulley 36, cam 37, the first One ordinary motor 38, the first shaft rod 39, the second pulley 310, the belt 311, the mixing bucket 312, the second pole 313, the stirring block 314, the first electric valve 315, the slide rail 4, the slide block 41, the first Spring 42, water bucket 43, filter screen 45, connecting rod 46, roller 47, hollow pipe 48 and second electric valve 410, the bottom of base plate 1 is connected with leg 2 front and rear, left and right, and the upper right side of base plate 1 is fixedly connected with first bracket 3. The first support 31 and the second support 32 are fixedly connected to the upper left side of the first support 3, the first support 31 is located below the second support 32, and the left side of the first s...

Embodiment 2

[0031] A medical plastic syringe recycling device, such as Figure 1-5 Shown, include bottom plate 1, supporting foot 2, first bracket 3, first pole 31, second bracket 32, first bearing 33, second bearing 34, rotating shaft 35, first pulley 36, cam 37, the first One ordinary motor 38, the first shaft rod 39, the second pulley 310, the belt 311, the mixing bucket 312, the second pole 313, the stirring block 314, the first electric valve 315, the slide rail 4, the slide block 41, the first Spring 42, water bucket 43, filter screen 45, connecting rod 46, roller 47, hollow pipe 48 and second electric valve 410, the bottom of base plate 1 is connected with leg 2 front and rear, left and right, and the upper right side of base plate 1 is fixedly connected with first bracket 3. The first support 31 and the second support 32 are fixedly connected to the upper left side of the first support 3, the first support 31 is located below the second support 32, and the left side of the first s...

Embodiment 3

[0034] A medical plastic syringe recycling device, such as Figure 1-5 Shown, include bottom plate 1, supporting foot 2, first bracket 3, first pole 31, second bracket 32, first bearing 33, second bearing 34, rotating shaft 35, first pulley 36, cam 37, the first One ordinary motor 38, the first shaft rod 39, the second pulley 310, the belt 311, the mixing bucket 312, the second pole 313, the stirring block 314, the first electric valve 315, the slide rail 4, the slide block 41, the first Spring 42, water bucket 43, filter screen 45, connecting rod 46, roller 47, hollow pipe 48 and second electric valve 410, the bottom of base plate 1 is connected with leg 2 front and rear, left and right, and the upper right side of base plate 1 is fixedly connected with first bracket 3. The first support 31 and the second support 32 are fixedly connected to the upper left side of the first support 3, the first support 31 is located below the second support 32, and the left side of the first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com