Asphalt desulfurization device and method

A desulfurization device and asphalt technology, applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve the problems of unstable calcium sulfate, human health hazards, and large infrastructure overdrafts, and achieve obvious desulfurization effects and simple products. , the effect of large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

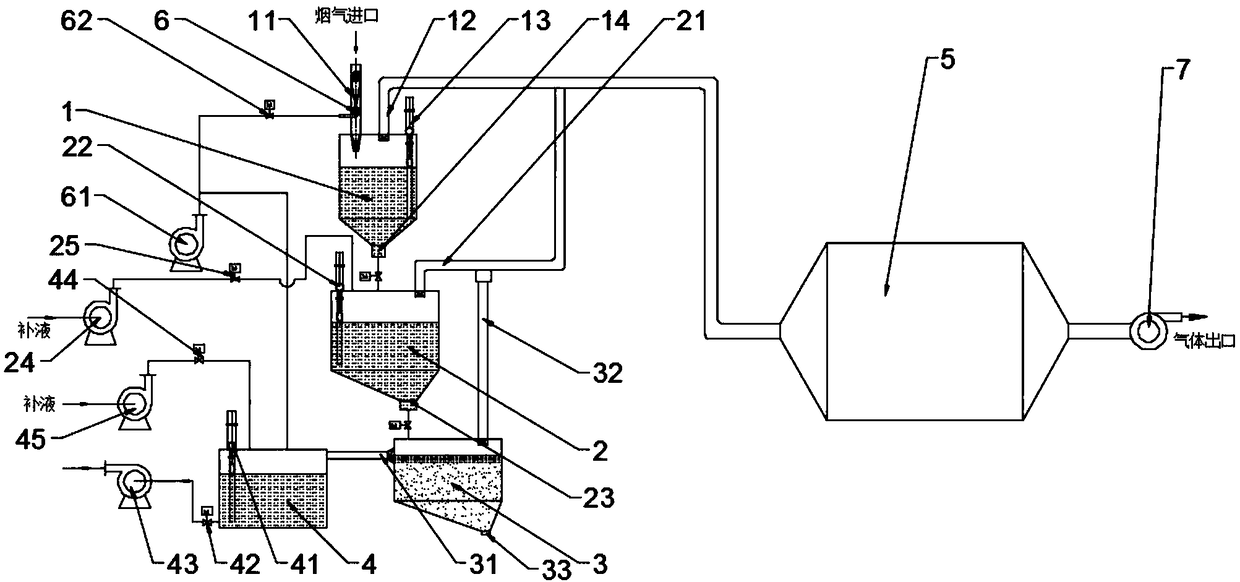

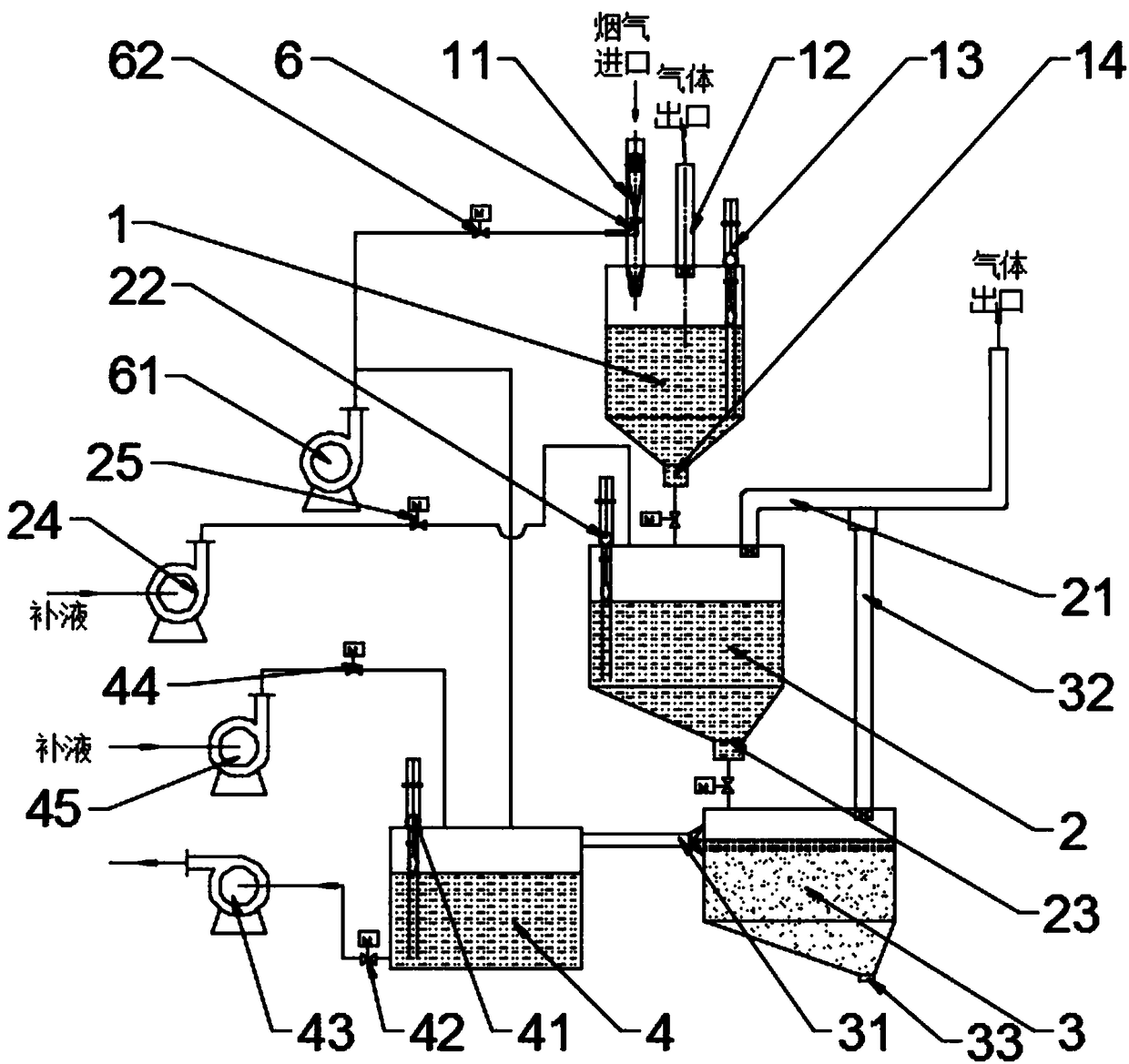

[0023] The present invention is described in further detail now in conjunction with accompanying drawing.

[0024] Such as figure 1 , figure 2 A kind of asphalt desulfurization device shown comprises a desulfurization tank 1, a regeneration tank 2, a settling tank 3, and a static tank 4. A desulfurization pipe 11 and a desulfurization gas outlet 12 are arranged above the desulfurization tank 1. The lower section of the desulfurization pipe 11 is provided with There is a nozzle 6, and the nozzle 6 is connected to the outlet of the high-pressure circulating water pump 61 through a pipeline, and the inlet of the high-pressure circulating water pump 61 is connected to the static tank 4 through a pipeline. The port 14 is connected to the regeneration tank 2 through a pipeline. The regeneration tank 2 is provided with a second liquid replenishment pipe and a regeneration gas outlet 21. The lower end of the regeneration tank 2 is provided with a regeneration drain port 23. The rege...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com