Flexible circuit three-dimensional printing device for high-molecular liquid-state metal co-printing

A technology of liquid metal and flexible circuits, applied in printed circuits, printed circuit manufacturing, electrical components, etc., can solve problems such as low production efficiency, unfavorable large-scale production, and complicated steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

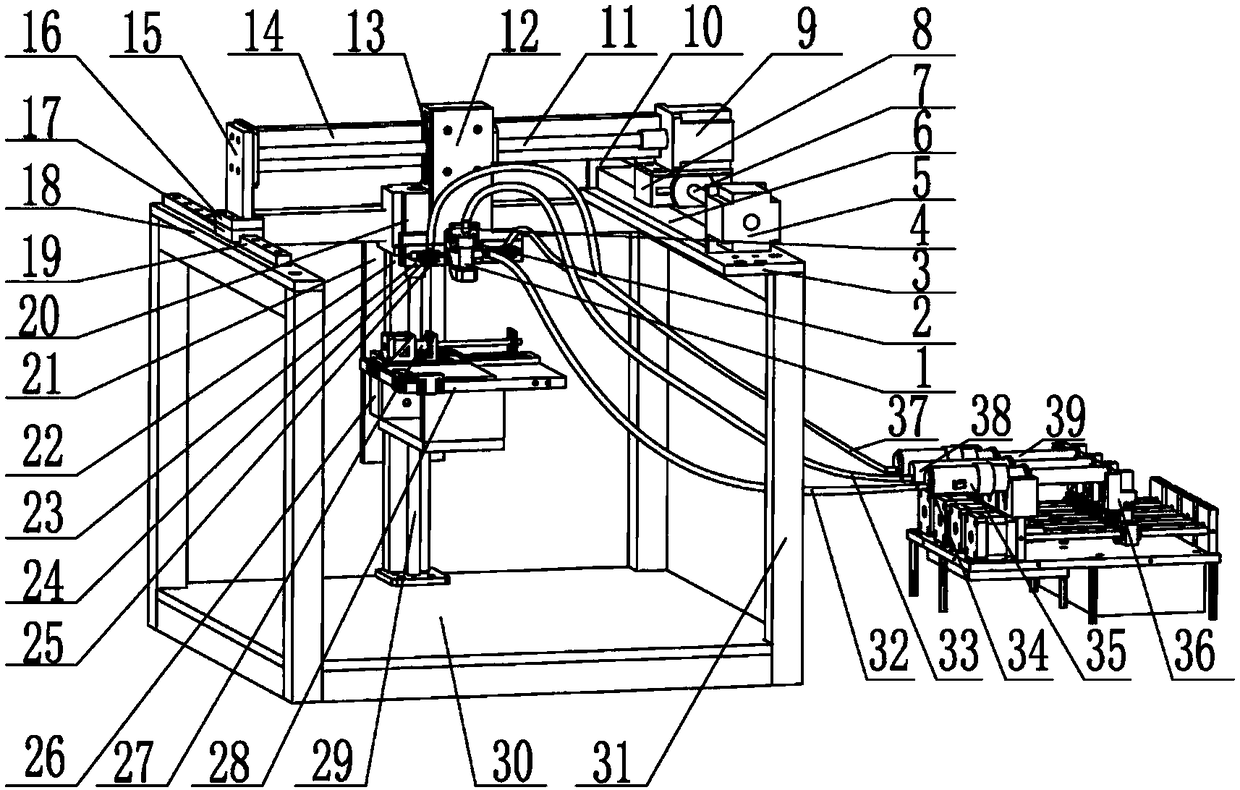

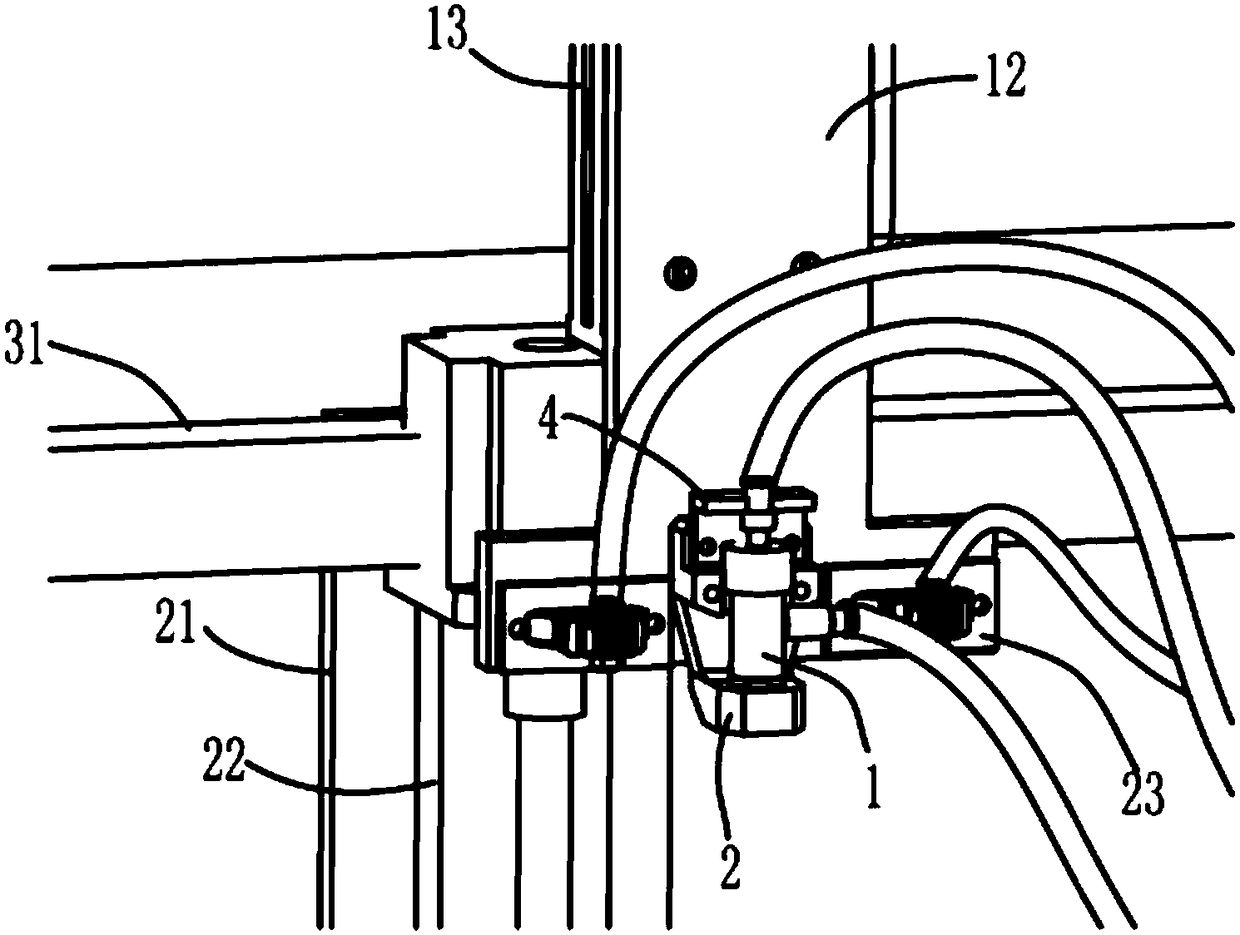

[0077] Such as figure 1 As shown, a flexible electronic three-dimensional printing device for polymer liquid metal co-printing, including an installation frame 31, a coaxial nozzle 1 installed on the installation frame 31 for printing, a three-dimensional motion mechanism, a feeding device, a receiving device, a control system, auxiliary curing device and heating unit 35. The control system can be realized by existing industrial computer or control chip. The installation frame 31 provides positioning and support for the whole device, and is the installation skeleton of the whole device.

[0078] The coaxial nozzle 1 includes an inner tube and an outer tube arranged coaxially. The inner tube forms an internal feeding chamber, and the outer tube and the wall of the inner tube form an external feeding chamber. The nozzle, the inner tube and the outer tube are gathered at the bottom to form a coaxial inner nozzle and an outer nozzle. The feeding port of the outer tube of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com