Skin-core structure fiber intelligent pattern and printing method and application thereof

A skin-core structure and intelligent technology, applied in the direction of 3D object support structure, additive manufacturing, coating device, etc., can solve the problems of complex personalized patterns, unable to print three-dimensional skin-core structure fibers, etc., to achieve low cost and selectivity Broad, simple-to-process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: A coaxial needle / 3D printing method for preparing personalized smart patterns

[0029] This embodiment provides a coaxial needle / 3D printing method for preparing personalized smart patterns, including:

[0030] (1) Preparation of slurry

[0031] The insulating cortex slurry is a slurry composed of water and silk fibroin, wherein the mass concentration ratio of the silk fibroin is 25%.

[0032] The conductive core layer slurry is a slurry composed of water, carbon nanotubes and a polyvinyl alcohol thickener, wherein the mass concentration of the carbon nanotubes is 5%, and the mass concentration of the polyvinyl alcohol thickener is 30%.

[0033] (2) Connect the coaxial printing needle to the 3D printing mobile terminal for printing to obtain personalized patterns

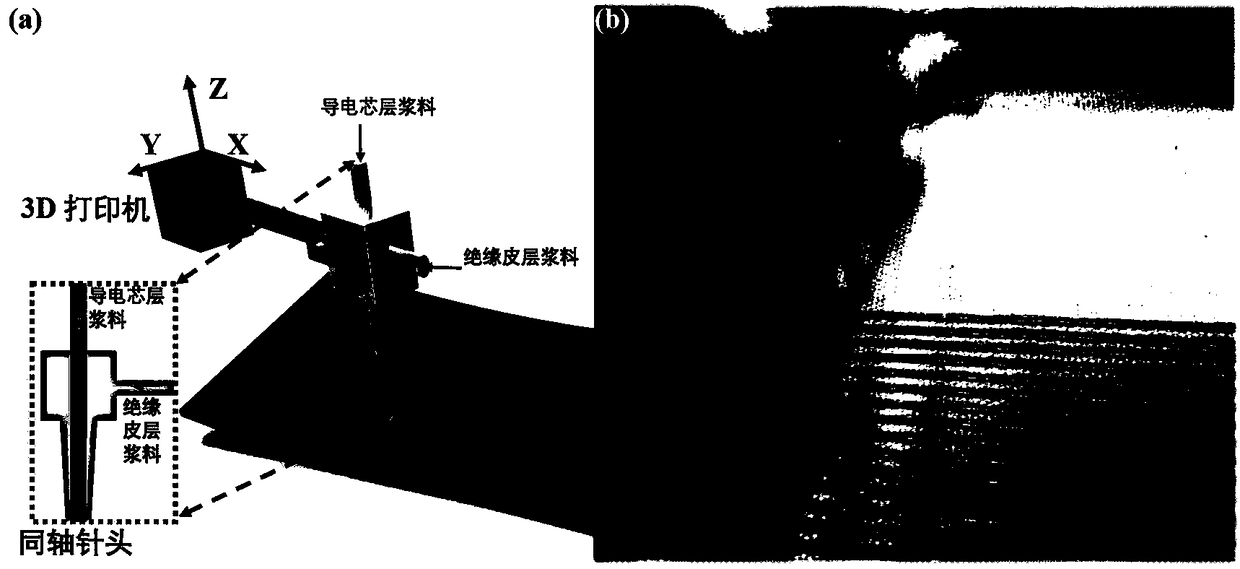

[0034] Specifically: the configuration of the coaxial needle is as follows figure 1 As shown in a, the needle of the outer layer is connected to the syringe equipped with silk fibroin slurry, an...

Embodiment 2 3

[0036] Example 2 Characterization of three-dimensional skin-core structural fibers and personalized patterns of their composition

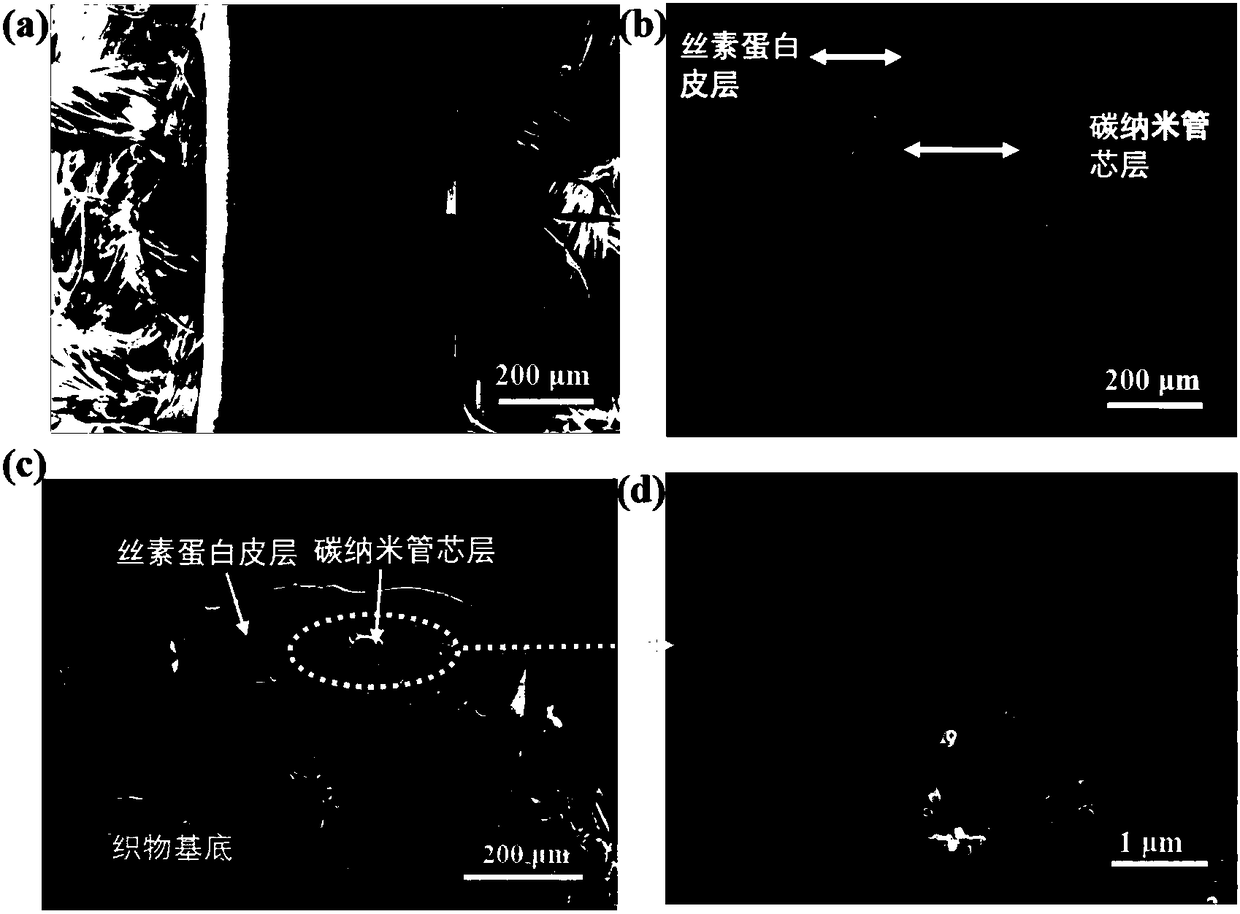

[0037] The three-dimensional skin-core structure fiber prepared in Example 1 is as follows: figure 2 shown. figure 2 a is the scanning electron microscope image of the three-dimensional skin-core structure fiber. The prepared three-dimensional skin-core structure fiber can exist stably on the fabric, and it is detected by the optical microscope ( figure 2 b) Observation shows that the core layer of carbon nanotubes is tightly covered by the outer layer of silk fibroin, forming a coaxial skin-core fiber structure. figure 2 c is the cross-section of the skin-core structure fiber. It can also be observed that the core layer is tightly wrapped, and the enlarged view of the core layer shows that the contact between carbon nanotubes constitutes its conductive channel.

[0038] The three-dimensional sheath-core structure fiber prepared in Example 1...

Embodiment 3

[0039]Example 3 Application of Smart Patterns on Fabrics for Triboelectric Power Generation

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com