Extraction method for material with antioxidant activity in peony leaves and method for preparing material into powder

A technology of antioxidant activity and extraction method, which is applied in the field of preparation of the above-mentioned antioxidant active material powder, can solve the problems of antioxidant toxicity, carcinogenicity, etc., and achieve the effects of good reproducibility, improved comprehensive utilization, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

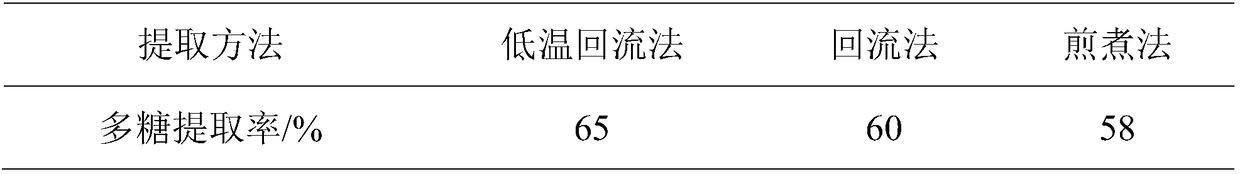

[0069] Step 1. Extract materials with antioxidant activity from peony leaves;

[0070] Step 1.1 Weigh an appropriate amount of peony leaves, add purified water according to the liquid-to-material ratio of 20:1, soak for 30min, and record it as material I;

[0071] Step 1.2 Extract the material I under reduced pressure and low temperature reflux for 70 minutes at a temperature of 70°C and a pressure of 0.08KPa. The mass ratio of the purified water added again to the remaining material after extraction is 20:1, and extracted under the same conditions. Merge the 2 extracts, and record it as material II;

[0072] Step 1.3 Place the material II at 70°C and 0.08KPa under reduced pressure and concentrate it to 0.4g / mL (the amount of raw material in g per mL), then centrifuge at a high speed at 5000r / min for 15min, collect the supernatant, and record it as Material III;

[0073] Step 1.4 Put the material III in a magnetic stirrer with a rotating speed of 40r / min, add absolute ethano...

Embodiment 2

[0082] Step 1. Extract materials with antioxidant activity from peony leaves;

[0083] Step 1.1 Weigh an appropriate amount of peony leaves, add purified water according to the liquid-to-material ratio of 20:1, soak for 20min, and record it as material I;

[0084] Step 1.2 Extract the material I under reduced pressure and low temperature reflux for 65 minutes at a temperature of 75°C and a pressure of 0.07KPa. The mass ratio of the purified water added again to the remaining material after extraction is 20:1, and extracted under the same conditions. Merge the 2 extracts, and record it as material II;

[0085] Step 1.3 Place the material II at 75°C and 0.09KPa under reduced pressure and concentrate it to 0.45g / mL (the amount of raw material in g per mL), then centrifuge at a high speed at 4000r / min for 10min, collect the supernatant, and record it as Material III;

[0086] Step 1.4 Put the material III in a magnetic stirrer with a rotating speed of 45r / min, add absolute ethan...

Embodiment 3

[0095] Step 1. Extract materials with antioxidant activity from peony leaves;

[0096] Step 1.1 Weigh an appropriate amount of peony leaves, add purified water according to the liquid-to-material ratio of 20:1, soak for 40min, and record it as material I;

[0097]Step 1.2 Extract the material I under reduced pressure and low temperature reflux for 60 minutes at a temperature of 80°C and a pressure of 0.06KPa. The mass ratio of the purified water added again to the remaining material after extraction is 20:1, and extracted under the same conditions. Merge the 2 extracts, and record it as material II;

[0098] Step 1.3 Place the material II at 80°C and 0.07KPa under reduced pressure and concentrate it to 0.6g / mL (the amount of raw material in g per mL), then centrifuge at 6000r / min for 12min at high speed, collect the supernatant, and record it as Material III;

[0099] Step 1.4 Put the material III in a magnetic stirrer with a rotating speed of 55r / min, add absolute ethanol, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com