Preparation method of low-viscosity middle/low temperature cured epoxy resin system catalyzed by nano molecular sieve-loaded anionic catalyst

A technology for curing epoxy resin and nano-molecular sieve, which is applied in the field of composite material preparation, can solve the problems of high curing temperature, high viscosity of epoxy resin, and narrow application range, and achieve good wettability, low curing temperature, and good manufacturability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

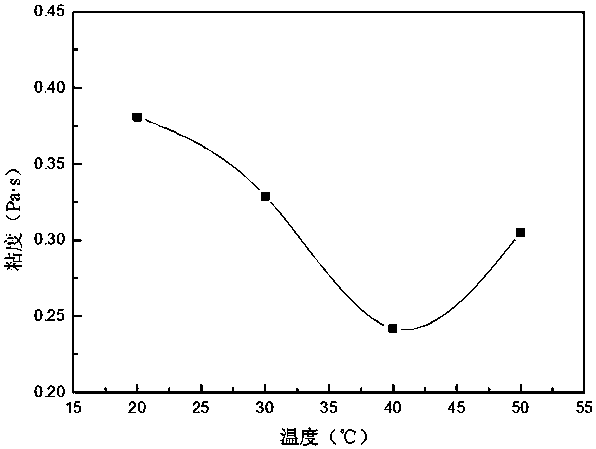

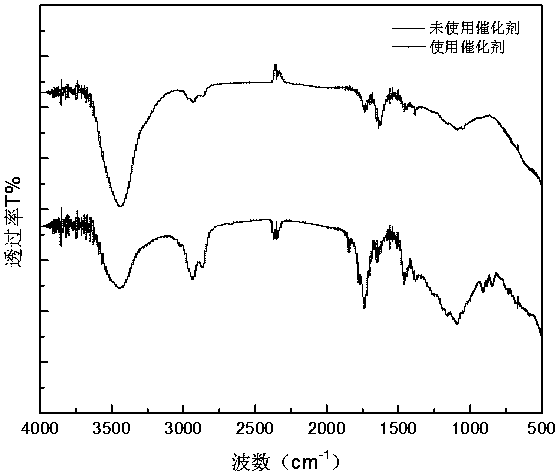

[0022] Specific embodiment 1: This embodiment records a preparation method of a low viscosity, medium and low temperature curing epoxy resin system catalyzed by a nano molecular sieve supported anion catalyst. The specific steps of the method are as follows:

[0023] Step 1: Preparation of aziridine / molecular sieve catalyst system:

[0024] (1) At room temperature, weigh 10-16 parts of aziridine and 15-30 parts of absolute ethanol, and mix the two to obtain a mixed solution of aziridine and ethanol;

[0025] (2) Weigh 0.5~2.5 parts of molecular sieve, put it in an oven, the temperature of the oven is 80~110℃, and the drying time is 30~45min to remove the moisture in the molecular sieve; among them, the oven is an electric heating constant temperature blast Drying box, purchased from Shanghai Yiheng Technology Co., Ltd., model DHG-9075A;

[0026] (3) Use the dipping method to immerse the mixed solution of aziridine and ethanol obtained in (1) on the molecular sieve treated in (2), and ...

specific Embodiment approach 2

[0029] Embodiment 2: The method for preparing a low-viscosity, low-viscosity, low-temperature curing epoxy resin system catalyzed by a nano-molecular sieve supported anionic catalyst described in the first embodiment. In step 1, the amount of aziridine is 10-12 parts, and the molecular sieve The number of parts is 0.5 to 1 part; in step two, the mass ratio of cycloaliphatic epoxy resin and methylhexahydrophthalic anhydride system to aziridine / molecular sieve catalyst system is 100:10.5~13.5; in step three, gradient curing The system is to cure at 20~30℃ for 3~4h, and then at 90~100℃ for 10~15h.

specific Embodiment approach 3

[0030] Specific embodiment three: a nano-molecular sieve supported anionic catalyst-catalyzed low-viscosity medium and low-temperature curing epoxy resin system preparation method described in specific embodiment one, in step one, the part of aziridine is 12-14 parts, molecular sieve The number of parts is 1~1.5 parts; in step 2, the mass ratio of cycloaliphatic epoxy resin and methylhexahydrophthalic anhydride system to aziridine / molecular sieve catalyst system is 100:13~15.5; in step 3, gradient curing The system is curing for 3~4h at 30~40℃, and then curing for 15~20h at 80~90℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com