A kind of silane crosslinked PE/eva water delivery hose and preparation method thereof

A silane cross-linking and hose technology, which is applied in the field of silane cross-linking PE/EVA water delivery hose and its preparation, can solve the problems of no antibacterial, narrow application range, poor transparency, etc., and achieves good softness and application range. Wide and excellent aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

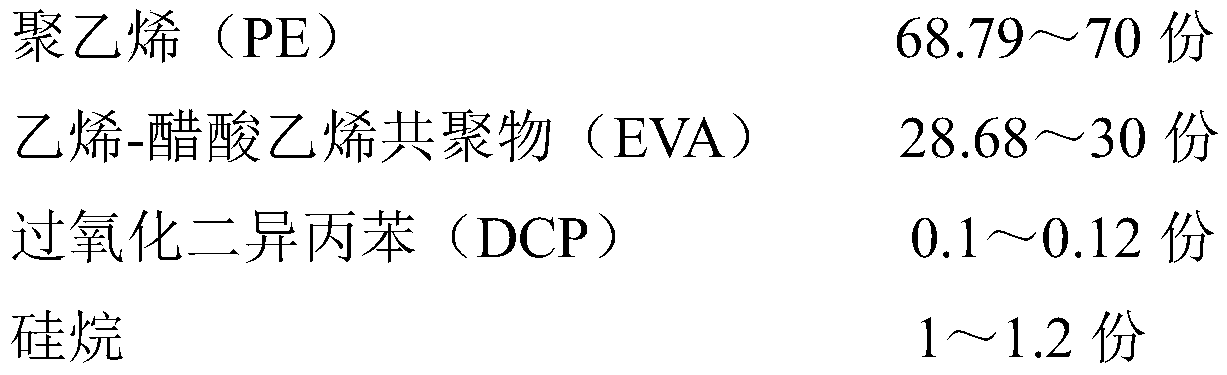

[0034] The water delivery hose of the present embodiment is made of the following parts by weight of material A and material B:

[0035] The mass percentage of A material is 85%, and the percentage of B material is 15%.

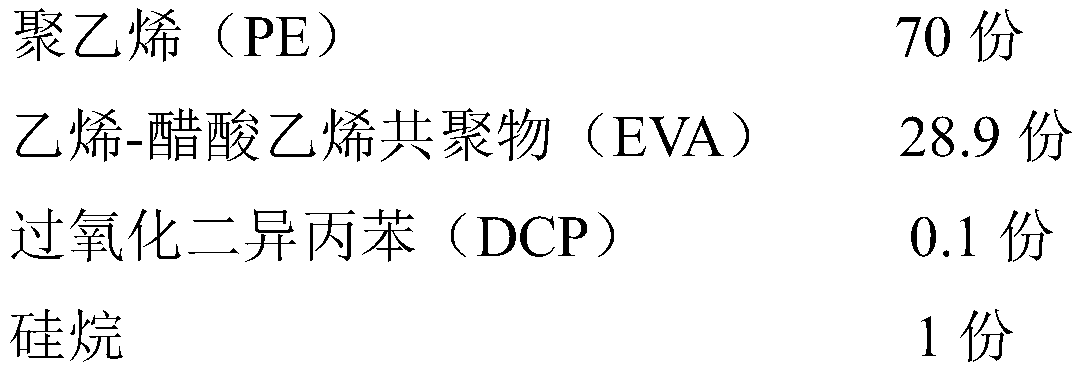

[0036] Based on 100 parts by weight, material A contains the following parts by weight: 70 parts of polyethylene (PE), 28.9 parts of ethylene-vinyl acetate copolymer (EVA), 0.1 part of dicumyl peroxide (DCP), 1 part of silane share;

[0037] Based on 100 parts by weight, material B contains the following components by weight: 97.8 parts of polyethylene (PE), 2 parts of silver-loaded calcium phosphate as an antibacterial agent, and 0.2 parts of catalyst dibutyltin dilaurate.

[0038] The preparation method of the present embodiment is as follows:

[0039] (1) Drying of raw materials: Polyethylene (PE) and ethylene-vinyl acetate copolymer (EVA) are dried at 60°C for 3 hours to keep the moisture content below 0.8%.

[0040] (2) Production of material A (silan...

Embodiment 2

[0044] The water delivery hose of the present embodiment is made of the following parts by weight of material A and material B:

[0045] The mass percentage of A material is 85%, and the percentage of B material is 15%.

[0046] Based on 100 parts by weight, material A contains the following components by weight: 68.79 parts of polyethylene (PE), 30 parts of ethylene-vinyl acetate copolymer (EVA), 0.11 parts of dicumyl peroxide (DCP), 1.1 parts of silane share;

[0047] Based on 100 parts by weight, material B contains the following components by weight: 97.7 parts of polyethylene (PE), 2 parts of antibacterial agent silver-loaded calcium phosphate, and 0.3 part of catalyst dibutyltin dilaurate.

[0048] The preparation method of the present embodiment is as follows:

[0049] (1) Drying of raw materials: Polyethylene (PE) and ethylene-vinyl acetate copolymer (EVA) were dried at 65°C for 2.8 hours to keep the moisture content below 0.8%.

[0050] (2) Production of material A...

Embodiment 3

[0054] The water delivery hose of the present embodiment is made of the following parts by weight of material A and material B:

[0055] The mass percentage of A material is 85%, and the percentage of B material is 15%.

[0056] Based on 100 parts by weight, material A contains the following components by weight: 70 parts of polyethylene (PE), 28.68 parts of ethylene-vinyl acetate copolymer (EVA), 0.12 parts of dicumyl peroxide (DCP), 1.2 parts of silane share;

[0057] Based on 100 parts by weight, material B contains the following components by weight: 97.6 parts of polyethylene (PE), 2 parts of antibacterial agent silver-loaded calcium phosphate, and 0.4 part of catalyst dibutyltin dilaurate.

[0058] The preparation method of the present embodiment is as follows:

[0059] (1) Drying of raw materials: Polyethylene (PE) and ethylene-vinyl acetate copolymer (EVA) were dried at 70°C for 2.6 hours to keep the moisture content below 0.8%.

[0060] (2) Production of material A (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com