Flame-retardant and fire-resistant cable material

A flame retardant and cable material technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of poor flame retardancy, poor fire resistance, short life, etc., to eliminate easy oxidation, good mechanical properties, Effect of high flame retardancy and fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

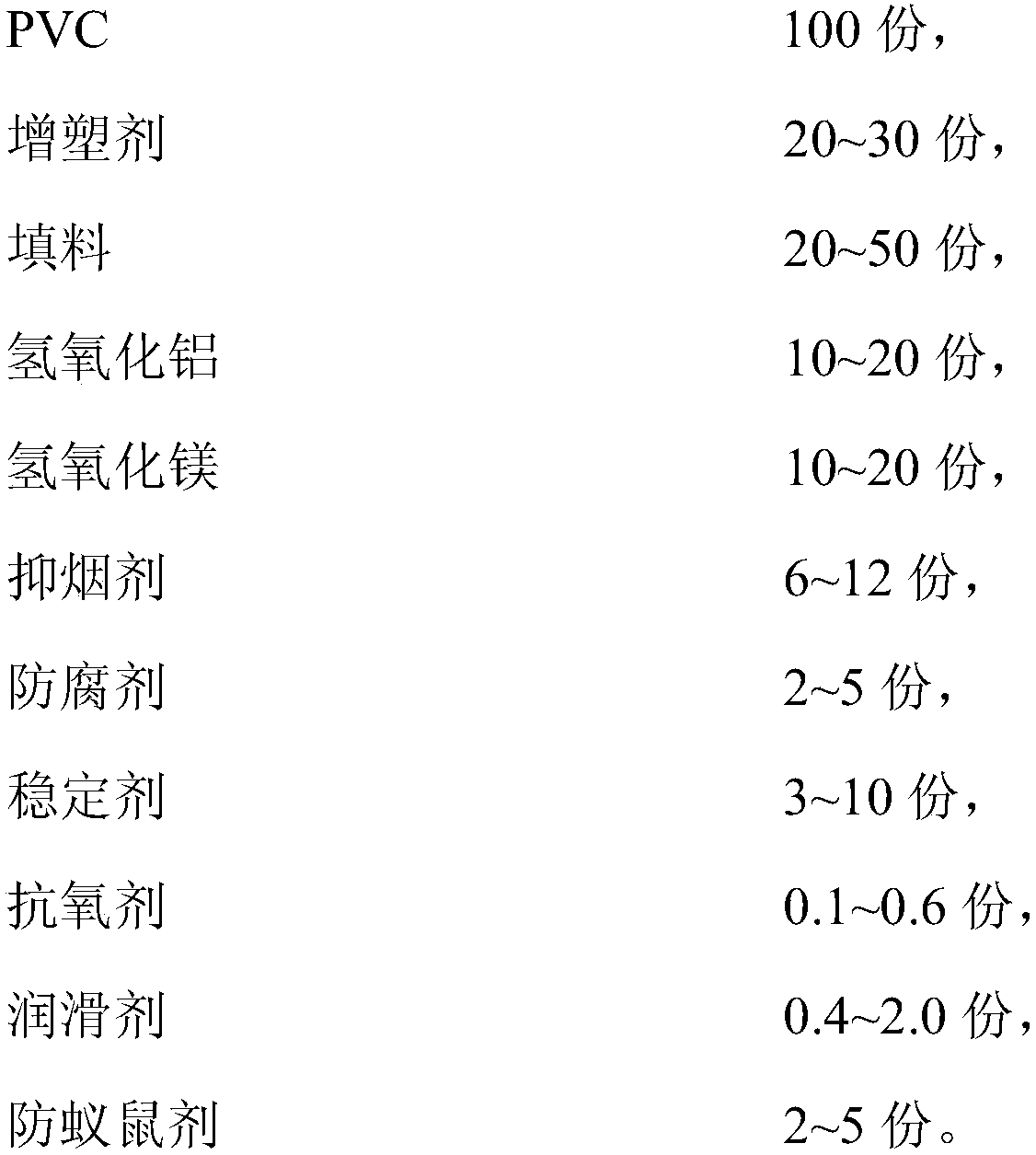

[0017] A flame-retardant and fire-resistant cable material, comprising the following raw materials by weight:

[0018]

[0019] The plasticizer includes a main plasticizer and a flame retardant plasticizer, the main plasticizer is DOTP, the flame retardant plasticizer is tetrabromophthalic anhydride; the filler is calcium carbonate; the smoke suppression The agent is zinc hydroxystannate; the preservative is SEBS, and the stabilizer is calcium zinc stabilizer; the preparation process of the flame-retardant and fire-resistant cable material is as follows: first, PVC, plasticizer, aluminum hydroxide, hydroxide Magnesium, smoke suppressants, preservatives, stabilizers, antioxidants, lubricants and rodent repellants are weighed according to the above proportions, and then the materials are preliminarily mixed evenly by mechanical stirring and ultrasonic treatment. Put it into the mixer, further mixing and stirring under the condition of 120 ℃, adding the filler after mixing uni...

Embodiment 2

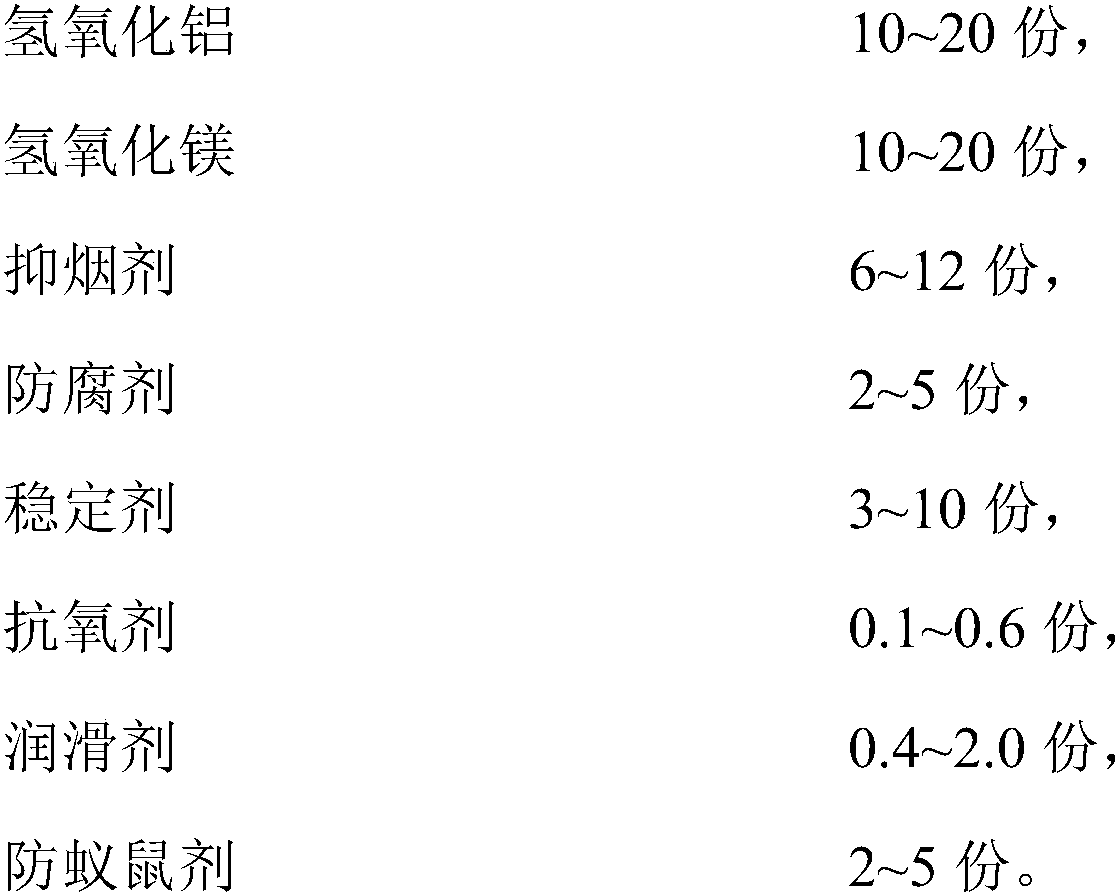

[0021] A flame-retardant and fire-resistant cable material, comprising the following raw materials by weight:

[0022]

[0023] The plasticizer includes a main plasticizer and a flame-retardant plasticizer, the main plasticizer is TOTM, the flame-retardant plasticizer is diaryl phosphate; the filler is calcium carbonate; The smoke agent is ammonium octamolybdate; the preservative is SEBS, and the stabilizer is calcium-zinc stabilizer; the preparation process of the flame-retardant and fire-resistant cable material is: firstly combine PVC, plasticizer, aluminum hydroxide, hydrogen Magnesium oxide, smoke suppressants, preservatives, stabilizers, antioxidants, lubricants and rodent repellants are weighed according to the above proportions, and then the materials are preliminarily mixed evenly by mechanical stirring and ultrasonic treatment. The material is put into the mixer, further mixed and stirred at 90 °C, and the filler is added after mixing evenly, and then mixed and st...

Embodiment 3

[0025] A flame-retardant and fire-resistant cable material, comprising the following raw materials by weight:

[0026]

[0027] The plasticizer includes a main plasticizer and a flame retardant plasticizer, the main plasticizer is epoxidized soybean oil, the flame retardant plasticizer is triaryl phosphate; the filler is calcium carbonate; The smoke suppressant is zinc hydroxystannate; the preservative is SEBS, and the stabilizer is calcium zinc stabilizer; the preparation process of the flame-retardant and fire-resistant cable material is as follows: first, PVC, plasticizer, aluminum hydroxide , Magnesium hydroxide, smoke suppressant, preservative, stabilizer, antioxidant, lubricant and rodent repellent are weighed according to the above-mentioned fixed proportions, and then the materials are preliminarily mixed evenly by mechanical stirring and ultrasonic treatment, and the The uniformly mixed material is put into the mixer, further mixed and stirred under the condition o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com