House leakage environmental protection maintenance method

An environmental protection and housing technology, which is applied in coating, construction material processing, construction, etc., can solve problems such as unreasonable use of materials, high repair costs, and incomplete maintenance, etc., and achieves safe and environmentally friendly construction methods, high cost performance and high construction efficiency. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

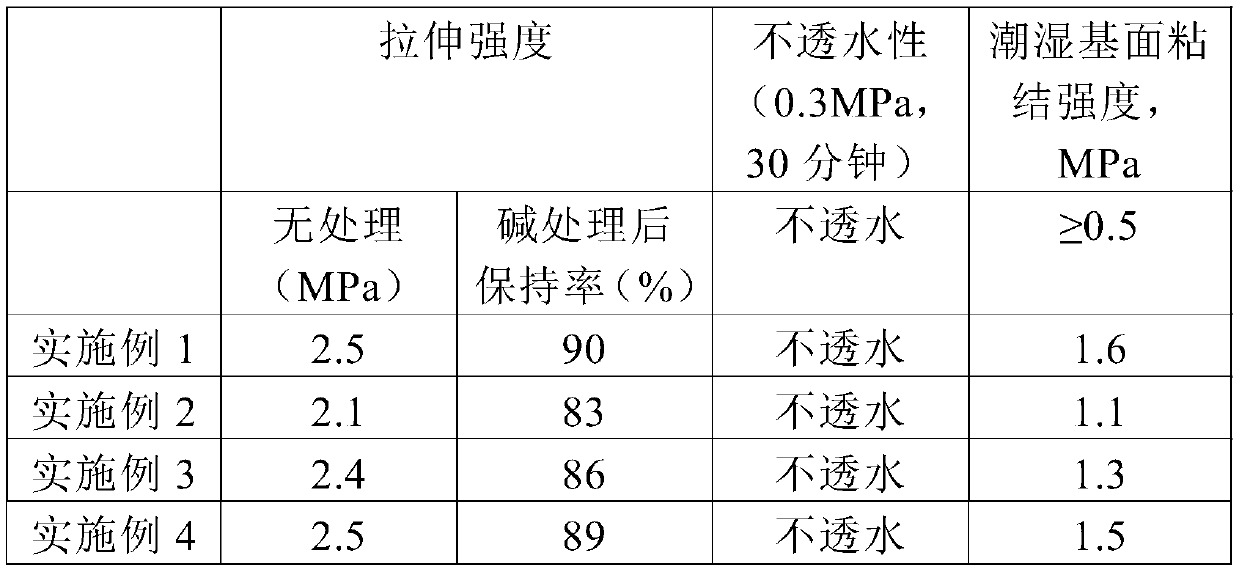

Embodiment 1

[0040] The environmental maintenance method for house leakage includes the following steps:

[0041] (1) Clean up the grass roots;

[0042] (2) Apply environmentally friendly waterproof paint with a thickness of 4mm and dry for 25 hours;

[0043] (3) Apply the environmentally friendly waterproof paint for the second time, with a thickness of 5mm and dry for 30 hours.

[0044] The environmental protection waterproof coating is prepared from the following raw materials in mass percentage: 4.5% of propylene glycol methyl ether acetate, 5% of sodium diisopropylnaphthalene sulfonate, 3.5% of silica sol, 3% of acetyl tributyl citrate, poly Carboxylate dispersant 3.5%, simethicone 0.45%, modified garnet powder 12%, ethylene glycol 5.5%, and the balance is silicone acrylic emulsion. Stir each raw material at a speed of 600r / min for 30 minutes and mix evenly to obtain an environmentally friendly waterproof coating.

[0045] The modified garnet powder is prepared by the following met...

Embodiment 2

[0047] The environmental maintenance method for house leakage includes the following steps:

[0048] (1) Clean up the grass roots;

[0049] (2) Apply environmentally friendly waterproof paint with a thickness of 4mm and dry for 25 hours;

[0050] (3) Apply the environmentally friendly waterproof paint for the second time, with a thickness of 5mm and dry for 30 hours.

[0051] The environmental protection waterproof coating is prepared from the following raw materials in mass percentage: 4.5% of propylene glycol methyl ether acetate, 5% of sodium diisopropylnaphthalene sulfonate, 3.5% of silica sol, 3% of acetyl tributyl citrate, poly Carboxylate dispersant 3.5%, simethicone 0.45%, garnet powder 12%, ethylene glycol 5.5%, and the balance is silicone acrylic emulsion. Stir each raw material at a speed of 600r / min for 30 minutes and mix evenly to obtain an environmentally friendly waterproof coating.

Embodiment 3

[0053] The environmental maintenance method for house leakage includes the following steps:

[0054] (1) Clean up the grass roots;

[0055](2) Apply environmentally friendly waterproof paint with a thickness of 4mm and dry for 25 hours;

[0056] (3) Apply the environmentally friendly waterproof paint for the second time, with a thickness of 5mm and dry for 30 hours.

[0057] The environmental protection waterproof coating is prepared from the following raw materials in mass percentage: 4.5% of propylene glycol methyl ether acetate, 5% of sodium diisopropylnaphthalene sulfonate, 3.5% of silica sol, 3% of acetyl tributyl citrate, poly Carboxylate dispersant 3.5%, simethicone 0.45%, modified garnet powder 12%, ethylene glycol 5.5%, and the balance is silicone acrylic emulsion. Stir each raw material at a speed of 600r / min for 30 minutes and mix evenly to obtain an environmentally friendly waterproof coating.

[0058] The modified garnet powder is prepared by the following meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com