Removing method for phosphorus in acid vanadium leaching liquid

A leachate and acidic technology, applied in the field of dephosphorization treatment, can solve the problems of complex process, unstable phosphorus removal effect, low phosphorus removal efficiency, etc., and achieve the effect of simple process, stable phosphorus removal effect and high phosphorus removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

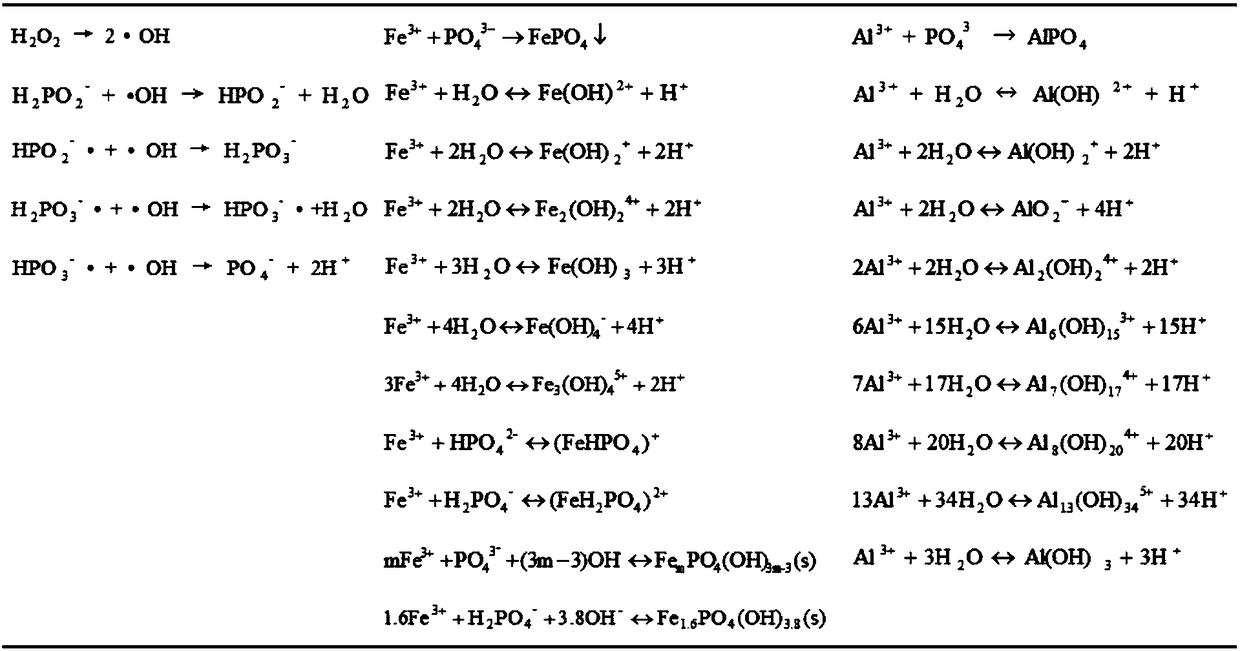

Method used

Image

Examples

Embodiment 1

[0033] A method for removing phosphorus in an acidic vanadium leaching solution, characterized in that it comprises the following steps:

[0034] 1) placing the acidic vanadium leaching solution in a container;

[0035] The pH value of described acidic vanadium leaching solution is 2.5, and wherein the concentration of phosphorus is 0.723g / L;

[0036] 2) Add oxidant A to the acidic vanadium leaching solution at 30°C, stir, and obtain mixed liquid A after 0.1 hour;

[0037] The oxidizing agent A is NaClO;

[0038] The mol ratio of described oxidizing agent A and phosphorus in the acidic vanadium leaching solution is 1: 1;

[0039] 3) Add a composite dephosphorization agent to the mixed liquid A obtained in step 2) at 30°C, stir, and obtain mixed liquid B after 0.1 hour;

[0040] The composite phosphorus removal agent includes component B and component C;

[0041] The molar ratio of the B component to phosphorus in the acidic vanadium leaching solution is 0.1:1;

[0042] Th...

Embodiment 2

[0050] A method for removing phosphorus in an acidic vanadium leaching solution, characterized in that it comprises the following steps:

[0051] 1) placing the acidic vanadium leaching solution in a container;

[0052] The pH value of described acidic vanadium leaching solution is 2.5, and wherein the concentration of phosphorus is 1.294g / L;

[0053] 2) At 20°C, use 0.1M NaOH solution to adjust the pH value of the acidic vanadium leaching solution to 3.0, add oxidant A to the acidic vanadium leaching solution, stir, and obtain mixed liquid A after 0.5 hours;

[0054] The oxidizing agent A is HClO;

[0055] The mol ratio of described oxidant A and phosphorus in the acid vanadium leaching solution is 5: 1;

[0056] 3) Add a composite dephosphorization agent to the mixed liquid A obtained in step 2) at 50°C, stir, and obtain mixed liquid B after 0.5 hours;

[0057] The composite phosphorus removal agent includes component B and component C;

[0058] The molar ratio of the phos...

Embodiment 3

[0066] A method for removing phosphorus in an acidic vanadium leaching solution, characterized in that it comprises the following steps:

[0067] 1) placing the acidic vanadium leaching solution in a container;

[0068] The pH value of described acidic vanadium leaching solution is 3.0, and wherein the concentration of phosphorus is 0.821g / L;

[0069] 2) At 60°C, use 0.1M NaOH solution to adjust the pH value of the acid vanadium leach solution to 4.5, add oxidant A to the acid vanadium leach solution, stir, and obtain mixed liquid A after 1 hour;

[0070] The oxidizing agent A is H 2 o 2 ;

[0071] The mol ratio of described oxidizing agent A and phosphorus in the acidic vanadium leaching solution is 10: 1;

[0072] 3) Add the composite dephosphorization agent to the mixed liquid A obtained in step 2) at 20°C, stir, and obtain the mixed liquid B after 1 hour;

[0073] The composite phosphorus removal agent includes component B and component C;

[0074] The molar ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com