Surface treatment method for brake caliper piston of vehicle

A surface treatment and vehicle braking technology, applied in the chemical field, can solve the problem of unsatisfactory salt bath compound treatment, etc., and achieve the effect of easy handling and easy collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

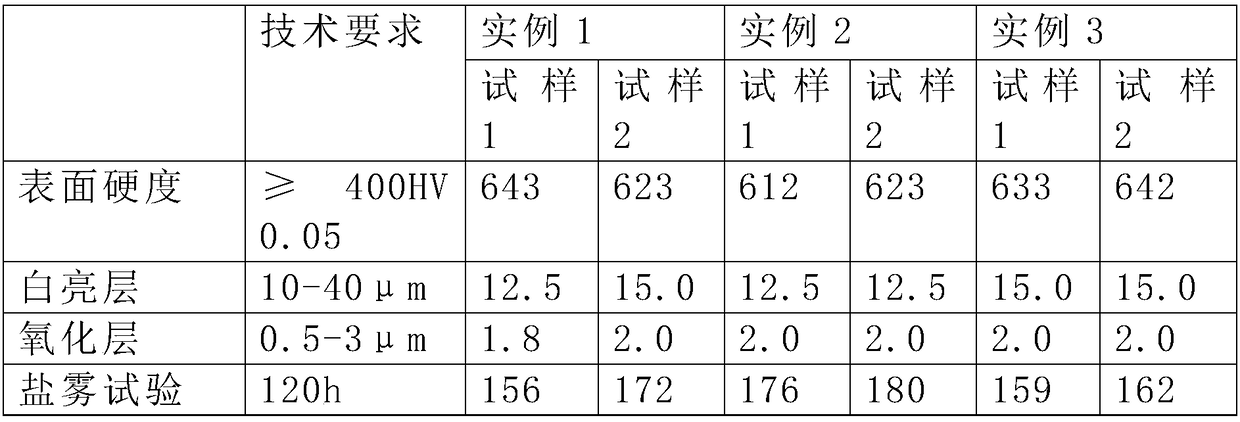

Examples

Embodiment 1

[0017] The process sequence steps of the vehicle brake caliper piston surface treatment method are as follows:

[0018] The first step of pre-processing: firstly, the opening of the caliper piston is facing down and clamped on the fixture. There should be a distance of 10mm to 20mm between two adjacent caliper pistons.

[0019] Then put the clamp and the caliper piston into the water-based cleaning agent, and use ultrasonic cleaning to peel off the dirt on the surface of the caliper piston.

[0020] Finally, put it into a heat treatment furnace after being controlled to dry.

[0021] The second step is pre-oxidation in air: heat the caliper piston to 350°C and keep it warm for 30 minutes; during this process, air can be allowed to enter the furnace naturally, or air can be introduced into the furnace.

[0022] The third step of nitrocarburizing: Heating the caliper piston to 500°C and holding it for 3 hours. During the holding period, pass ammonia gas into the furnace and dro...

Embodiment 2

[0026] The process sequence steps of the vehicle brake caliper piston surface treatment method are as follows:

[0027] The first step of pre-processing: firstly, the opening of the caliper piston is facing down and clamped on the fixture. There should be a distance of 10mm to 20mm between two adjacent caliper pistons.

[0028] Then put the clamp and the caliper piston into the water-based cleaning agent, and use ultrasonic cleaning to peel off the dirt on the surface of the caliper piston.

[0029] Finally, put it into a heat treatment furnace after being controlled to dry.

[0030] The second step is pre-oxidation in air: heat the caliper piston to 400°C and keep it warm for 40 minutes; during this process, air can be allowed to enter the furnace naturally, or air can be introduced into the furnace.

[0031] The third step of nitrocarburizing: Heating the caliper piston to 570°C and holding it for 2 hours. During the holding period, feed ammonia gas into the furnace and dro...

Embodiment 3

[0035] The process sequence steps of the vehicle brake caliper piston surface treatment method are as follows:

[0036] The first step of pre-processing: firstly, the opening of the caliper piston is facing down and clamped on the fixture. There should be a distance of 10mm to 20mm between two adjacent caliper pistons.

[0037] Then put the clamp and the caliper piston into the water-based cleaning agent, and use ultrasonic cleaning to peel off the dirt on the surface of the caliper piston.

[0038] Finally, put it into a heat treatment furnace after being controlled to dry.

[0039] The second step is pre-oxidation in air: heat the caliper piston to 450°C and keep it warm for 50 minutes; during this process, air can be allowed to enter the furnace naturally, or air can be introduced into the furnace.

[0040] The third step of nitrocarburizing: Heating the caliper piston to 600°C and holding it for 1 hour. During the holding period, pass ammonia gas into the furnace and drop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com