Novel optimized prebaked anode recipe for aluminum electrolysis

A technology of prebaked anodes and aluminum electrolysis, which is applied in the field of improving the production stability of prebaked anodes for aluminum electrolysis, and can solve problems such as electrolyte carbon content, accelerated consumption of prebaked anodes, and weakened electrochemical action, so as to reduce internal defects , Excellent carbon consumption index, small process changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

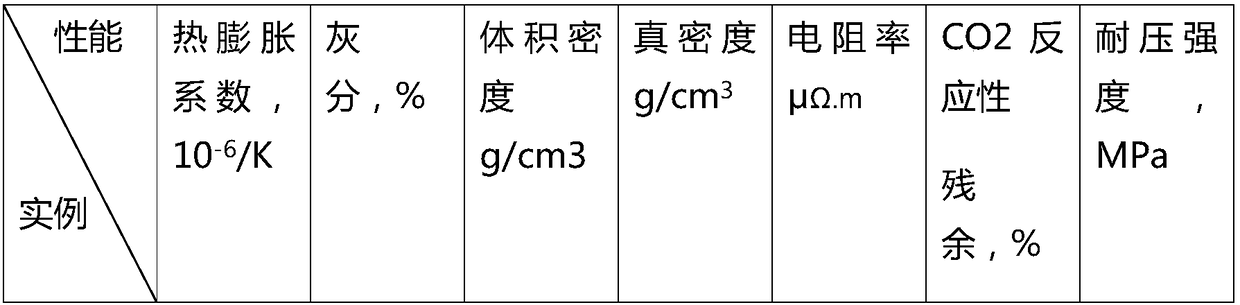

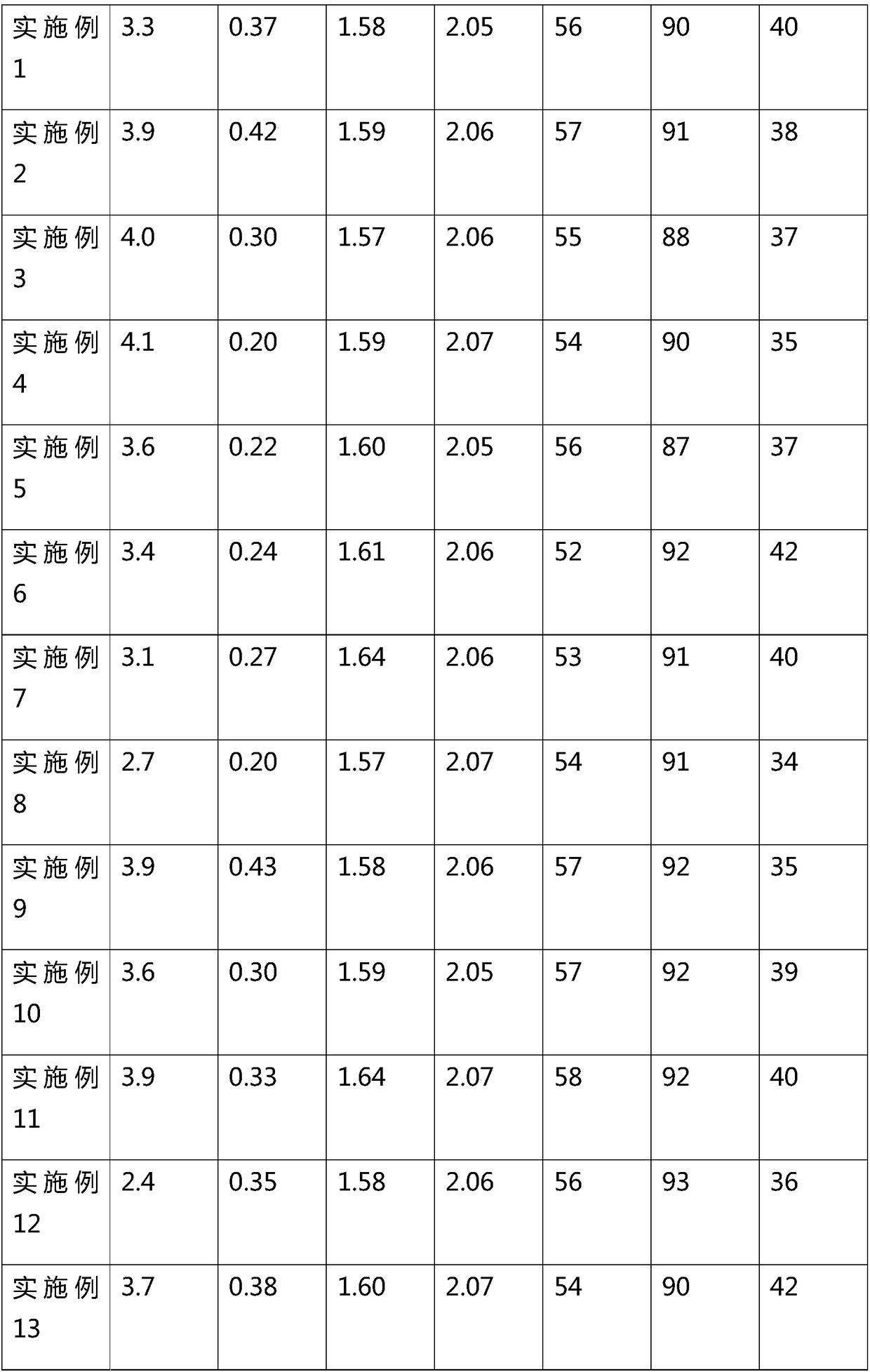

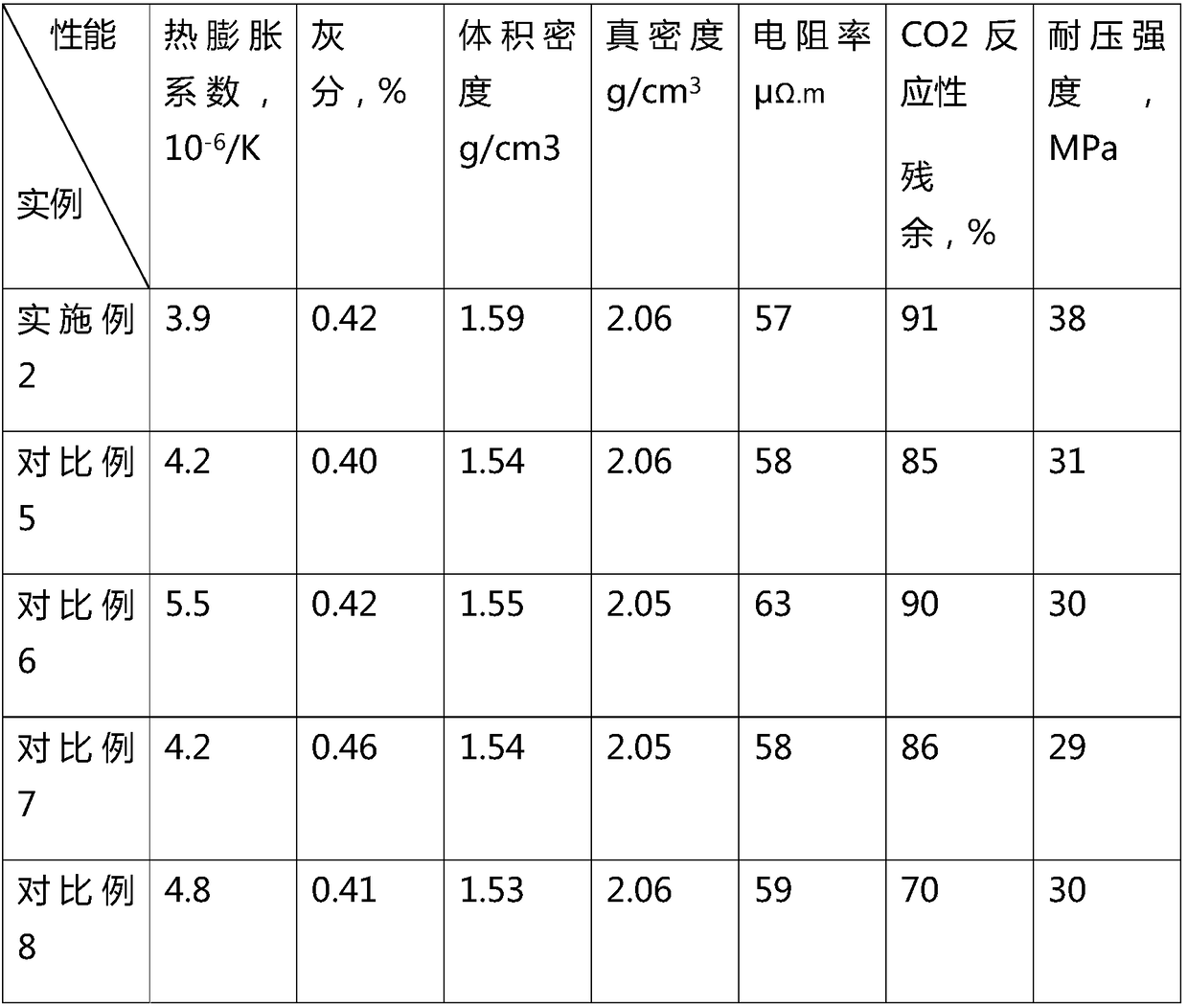

Examples

Embodiment 1

[0089] Embodiment 1 A kind of novel optimized aluminum electrolysis prebaked anode formula

[0090] The total weight of the paste is 4000kg, of which:

[0092] Calcined petroleum coke 3372kg.

[0093] The calcined petroleum coke is a mixture of four calcined petroleum coke materials with different particle sizes, and the quality of the mixture is respectively:

[0094] 978 kg of calcined petroleum coke pellets with a particle size of 3-6 mm;

[0095] 708 kg of calcined petroleum coke pellets with a particle size of 1-3 mm;

[0096] Calcined petroleum coke powder 1315kg (the quality of the powder whose particle size is less than 0.075mm is 750kg);

[0097] 371 kg of calcined petroleum coke pellets with a particle size of less than 1 mm.

[0098] Preparation:

[0099] (1) Raw material preparation: the coal tar pitch was melted and left standing for later use, and it was used up within 72 hours; the petroleum coke was calcined, crushed, and si...

Embodiment 2

[0103] Embodiment 2 A kind of novel optimized aluminum electrolysis prebaked anode formula

[0104] The total weight of the paste is 4000kg, of which:

[0105] Coal tar pitch 588kg;

[0106] Calcined petroleum coke 3412kg.

[0107] The calcined petroleum coke is a mixture of four calcined petroleum coke materials with different particle sizes, and the quality of the mixture is respectively:

[0108] 954 kg of calcined petroleum coke pellets with a particle size of 3-6 mm;

[0109] 615 kg of calcined petroleum coke pellets with a particle size of 1-3 mm;

[0110] Calcined petroleum coke powder 1256kg (the quality of the powder with particle size less than 0.075mm is 752kg);

[0111] 587 kg of calcined petroleum coke pellets with a particle size of less than 1 mm.

[0112] Preparation:

[0113] (1) Raw material preparation: the coal tar pitch was melted and left standing for later use, and it was used up within 72 hours; the petroleum coke was calcined, crushed, and sieved...

Embodiment 3

[0117] Embodiment 3 A kind of novel optimized aluminum electrolysis prebaked anode formula

[0118] The total weight of the paste is 4000kg, of which:

[0119] Coal tar pitch 596kg;

[0120] Calcined petroleum coke 3404kg.

[0121] The calcined petroleum coke is a mixture of four calcined petroleum coke materials with different particle sizes, and the quality of the mixture is respectively:

[0122] 978 kg of calcined petroleum coke pellets with a particle size of 3-6 mm;

[0123] 619 kg of calcined petroleum coke pellets with a particle size of 1-3 mm;

[0124] Calcined petroleum coke powder 1259kg (wherein the quality of the powder with particle size less than 0.075mm is 755kg);

[0125] 548 kg of calcined petroleum coke pellets with a particle size of less than 1 mm.

[0126] Preparation:

[0127] (1) Raw material preparation: the coal tar pitch was melted and left standing for later use, and it was used up within 72 hours; the petroleum coke was calcined, crushed, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com