Dissimilar steel electron beam welding line ultrasonic testing test block and test method

An electron beam weld seam and ultrasonic testing technology, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measuring devices. It can solve the problems of poor applicability, positioning, and quantification of ordinary ultrasonic testing methods. Errors, difficult identification and other problems, to achieve the effect of solving ultrasonic testing problems, ensuring welding quality, and high defect detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to facilitate the understanding of the technical means, creative features, and objectives achieved by the present invention, the present invention will be further explained below in conjunction with embodiments, but the scope of protection claimed by the present invention is not limited to the scope described in the specific embodiments.

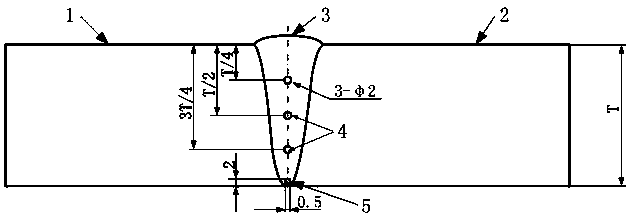

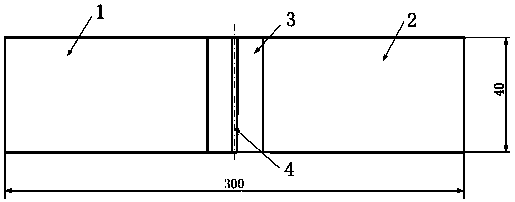

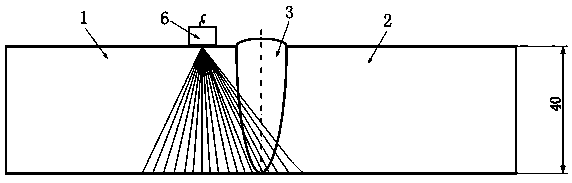

[0037] A test block for ultrasonic testing of dissimilar steel electron beam welds, such as figure 1 As shown, the test block is composed of base material I1 and base material II2 with a thickness of T. There is a butt welding seam 3 between base material I1 and base material II2 for connecting the two. Among them, base material I1 and base material The material of II2 is the same as that of the dissimilar steel to be tested, the thickness of the test block is the same as that of the dissimilar steel to be tested, and the welding process of the butt weld 3 is exactly the same as that of the electron beam welding in the dissimilar ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com