Converter power module hedging test system

A technology of power module and test system, applied in the field of test system of inverter power module, can solve the problems of large test power consumption, increase of test device cost, and high labor cost, so as to reduce construction cost, power supply capacity and power loss. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

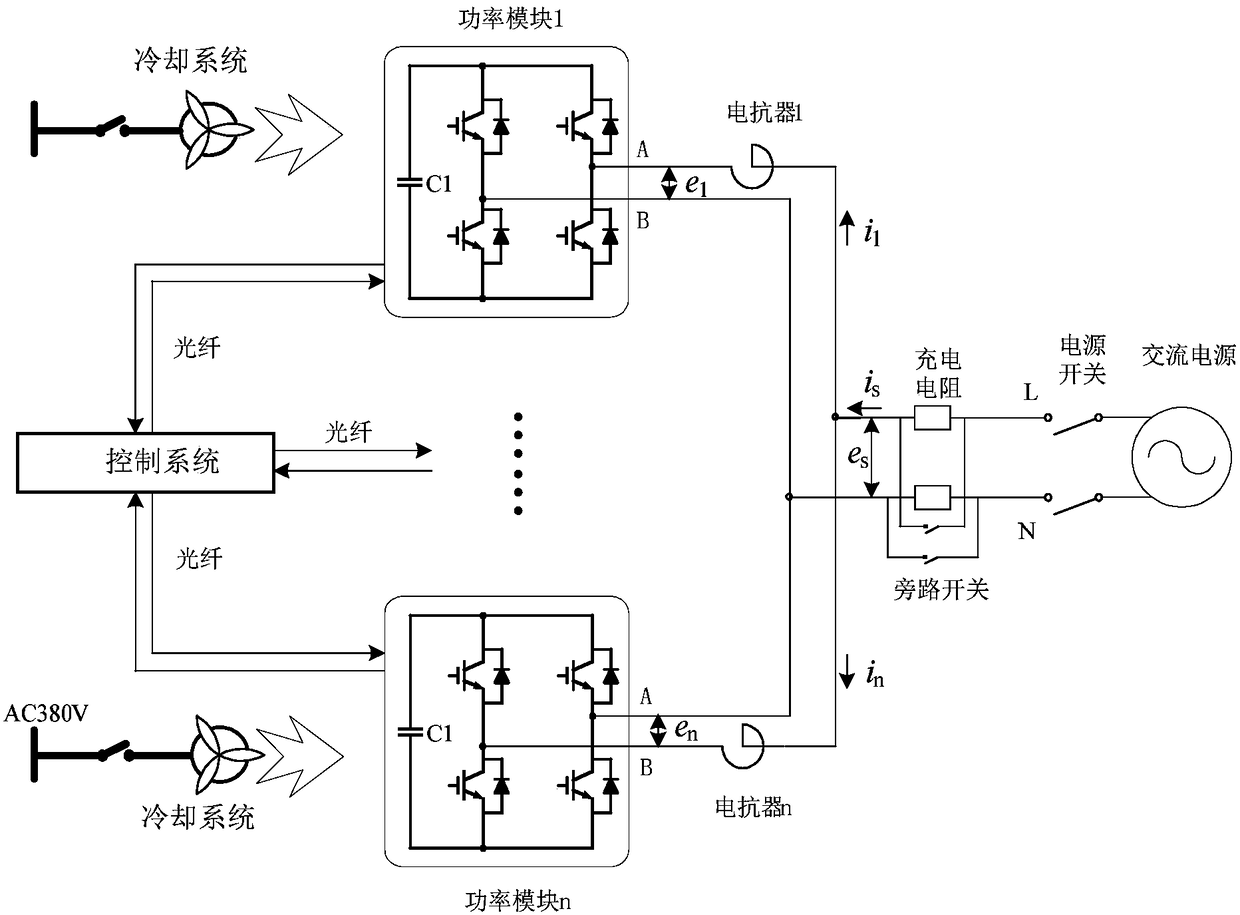

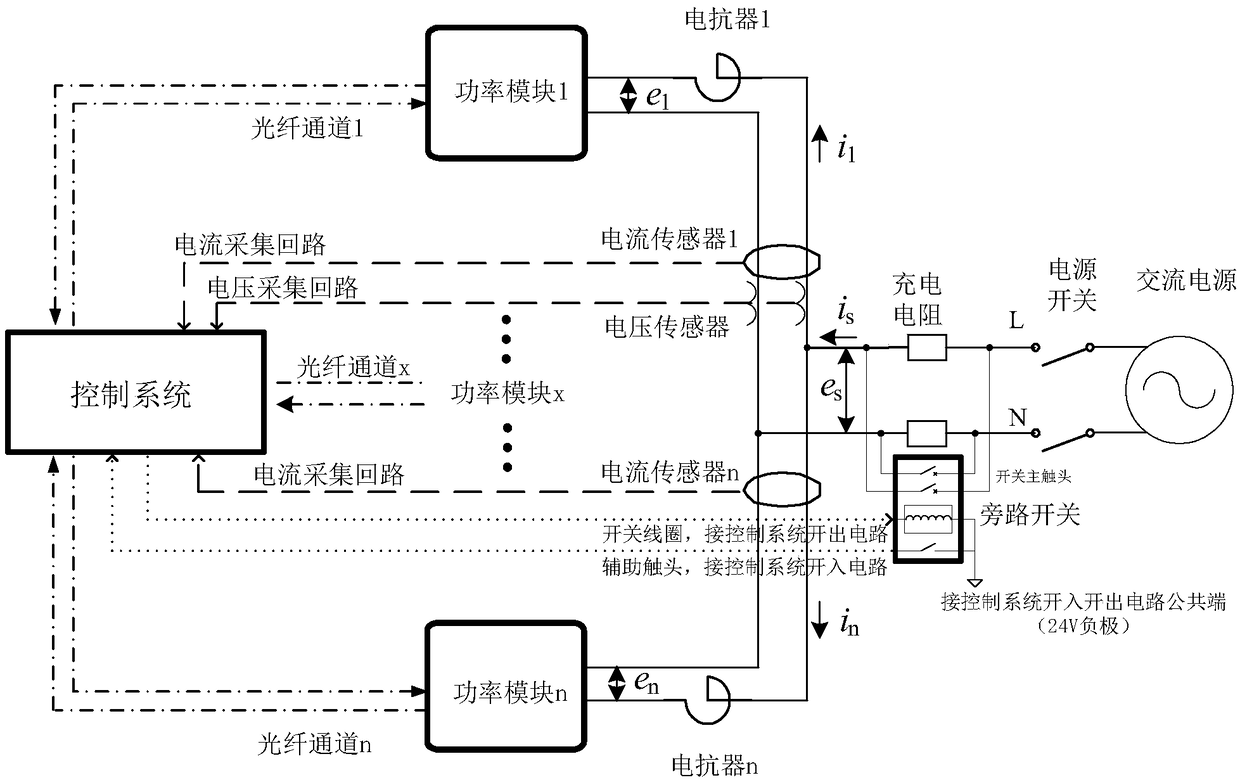

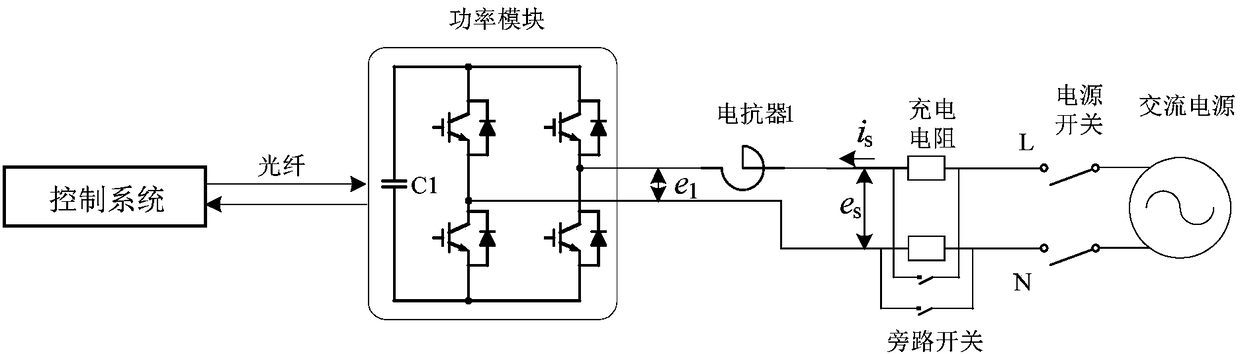

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. Such as figure 1 As shown, the inverter power module hedging test system (system) of the present invention is provided with a power supply system, a control system, 2-2n sets of reactors, and 2-2n sets of cooling systems. 2-2n sets of reactors are respectively electrically connected to 2-2n sets of power modules under test (power modules), and the control system is connected to 2-2n sets of power modules under test respectively through optical fiber channels. The number of n is 2-50.

[0023] The power supply system supplies power to the power module through the reactor, and the power system is composed of AC power supply, power switch, charging resistor and bypass switch. The live wire of the AC power supply is connected to the AC port A of the power module under test through the live wire power switch L, the first charging resistor, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com