Air fuel cell and air channel structural member, assembly and box body structure

An air channel and structural part technology, applied in structural parts, battery pack parts, hybrid battery parts, etc., can solve the problems of low electrochemical reaction efficiency and slow internal air circulation, and improve the electrochemical reaction efficiency and structure. Reasonable and easy to promote

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

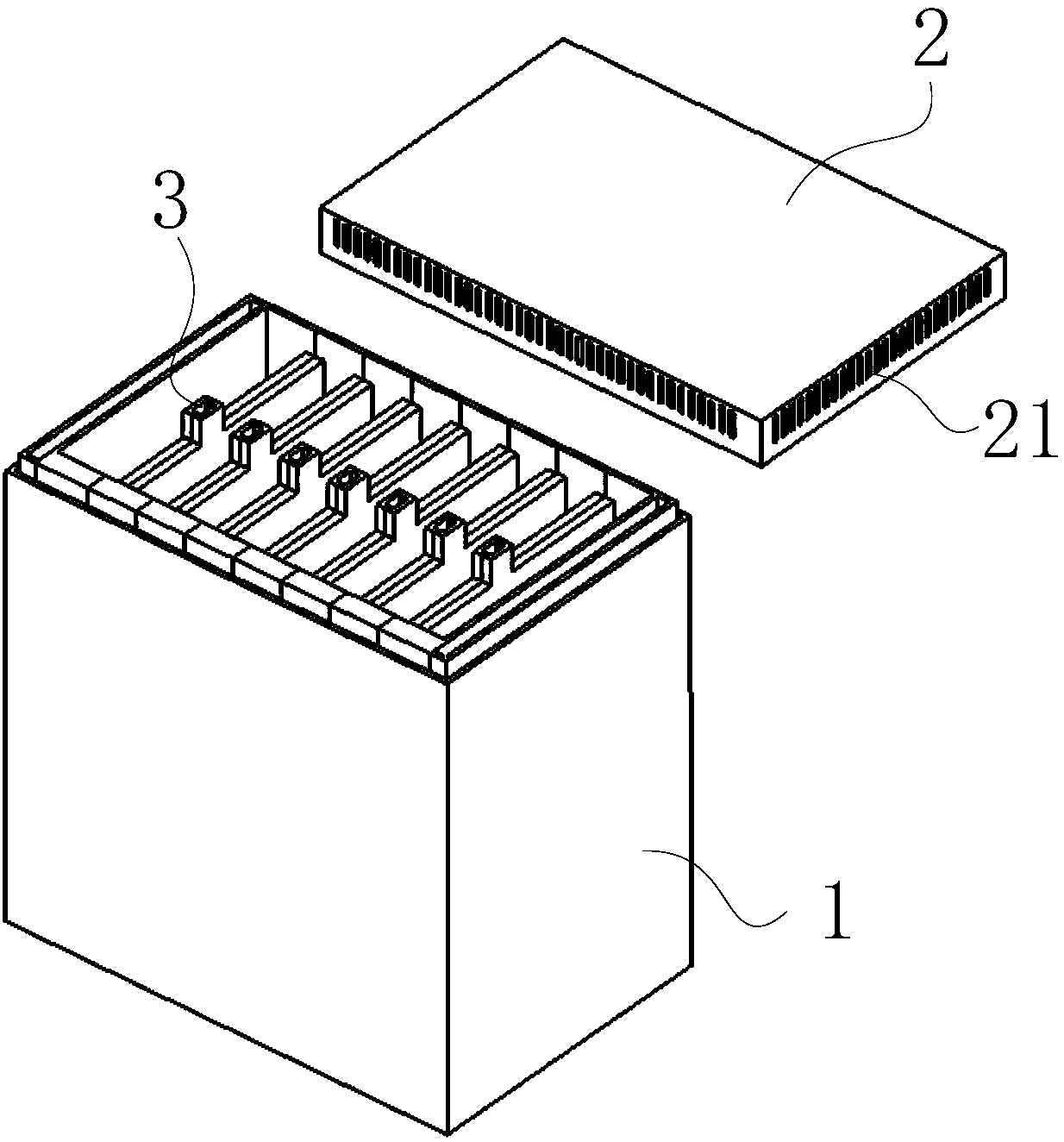

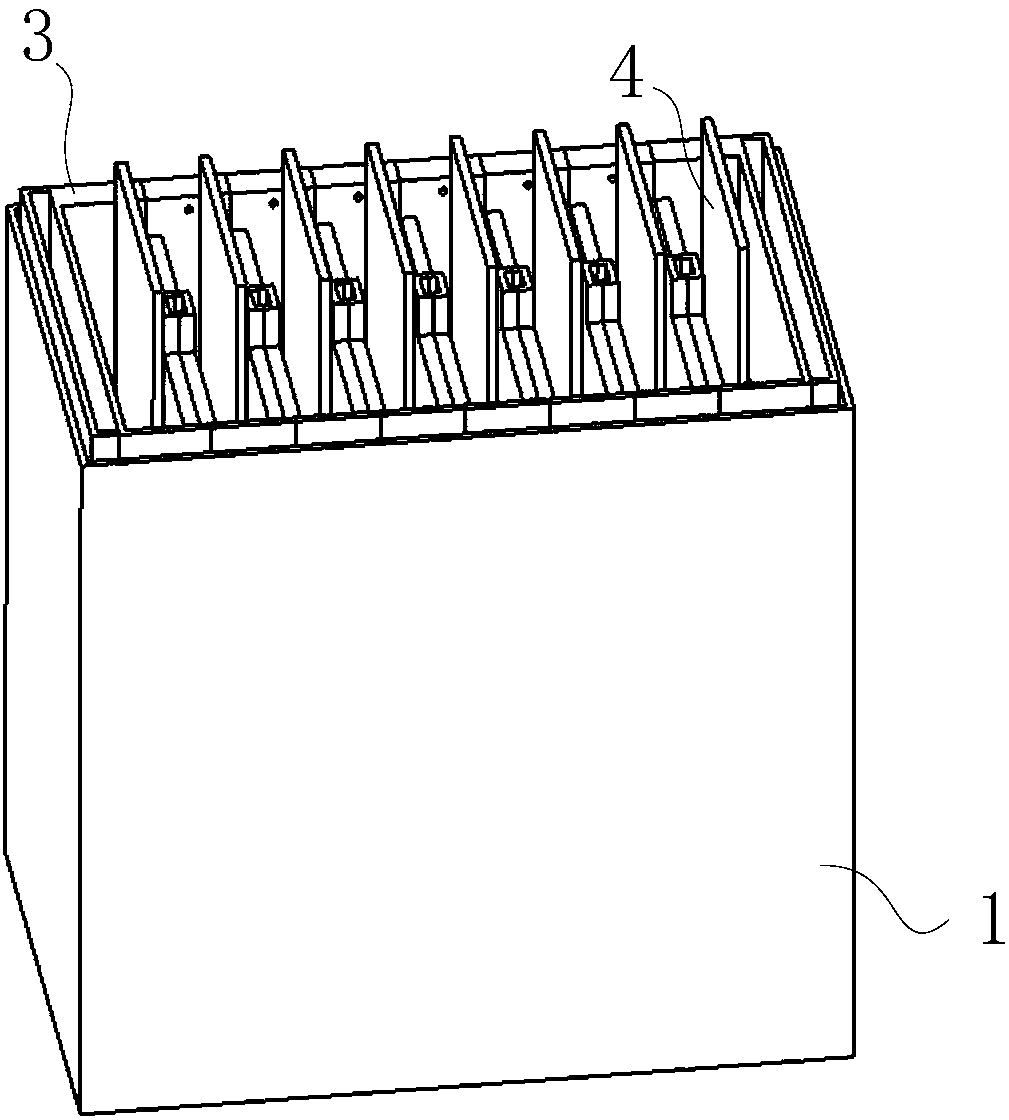

[0042] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

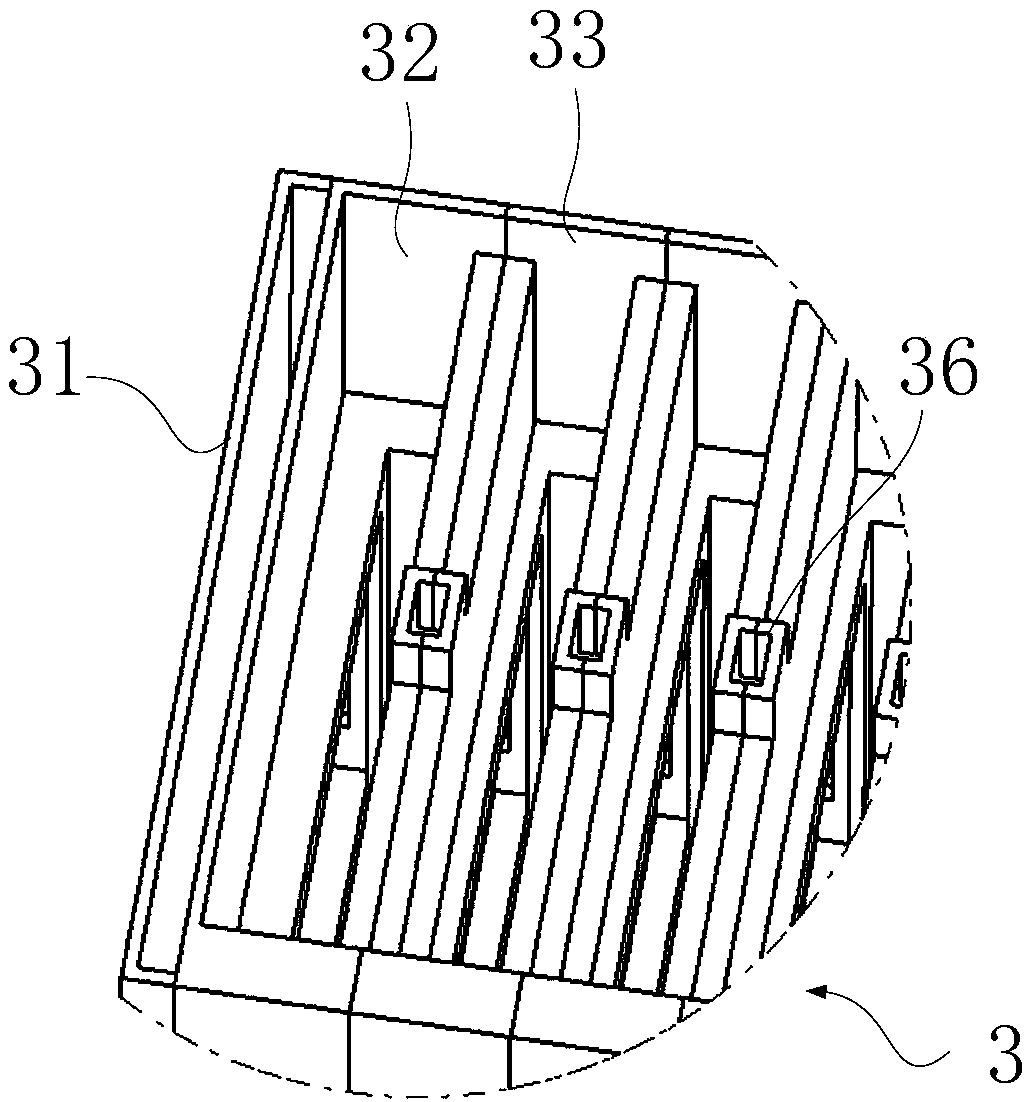

[0043] The air channel structure of the present invention, such as Figure 7-11 As shown, it includes a component body 33; the component body 33 includes two parallel channel separation surfaces 330 and a liquid inlet 38; the middle part of the channel separation surface 330 is an open structure; the two channel separation surfaces 330 are connected as a whole through side plates; The liquid port 38 is located at one end of the two-channel separating surface 330; the other end of the two-channel separating surface 330 is provided with an air outlet groove 334; the channel separating surface 330 is also provided with an air inlet through groove 34; The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com