Lithium ion battery and preparation method of nickel oxide-nickel-nickel oxide nanotube array

A nanotube array and lithium-ion battery technology, applied in the field of lithium-ion batteries, can solve the problems of reduced production efficiency, increased production cost, battery system power, rate and cycle performance deterioration, to reduce interface contact resistance and improve utilization rate , the effect of improving the efficiency of electrochemical reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

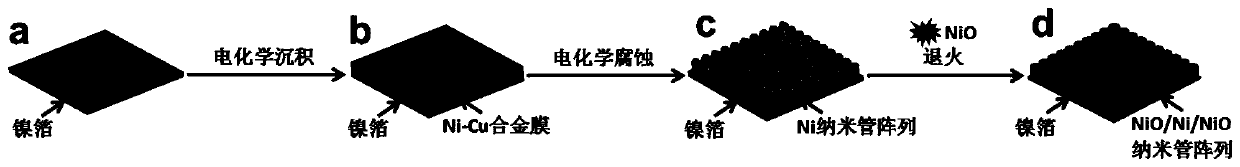

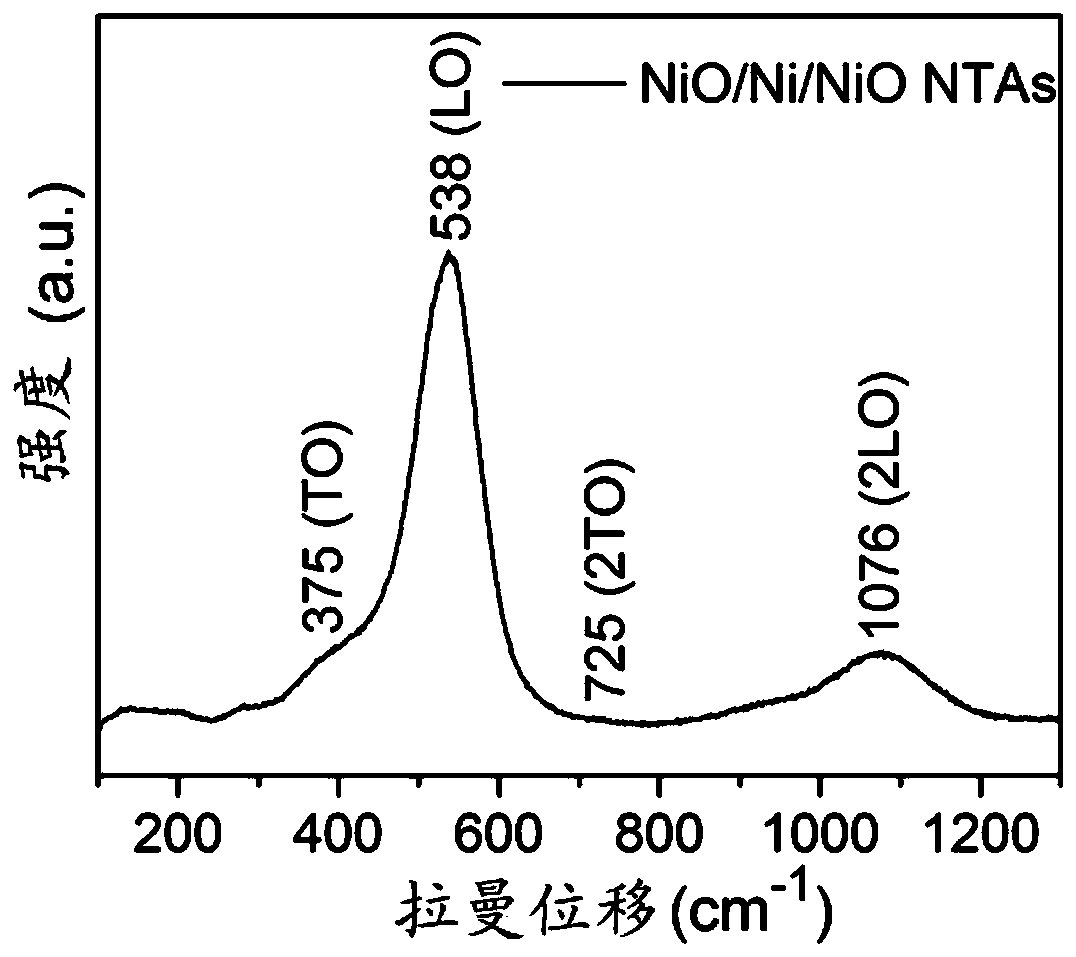

[0034] The invention provides a method for preparing a nickel oxide-nickel-nickel oxide nanotube array with a sandwich structure. The nickel nanotube array is prepared on a nickel foil by electrochemical deposition and electrochemical corrosion techniques, and then annealed.

[0035] Specifically, see figure 1 , the preparation method of nickel oxide-nickel-nickel oxide nanotube array according to one embodiment of the present invention, comprises the following steps:

[0036] Step 1. Electrochemical deposition of Ni on nickel foil (a) x Cu 100-x Alloy film (b), wherein x=30~80;

[0037] Step 2, to the Ni x Cu 100-x The alloy film is dealloyed to obtain a nickel film with an oxide film on the surface;

[0038] Step 3, soaking the nickel film in an acidic aqueous solution to remove the oxide film on the surface of the nickel film;

[0039] Step 4, heating the nickel film treated in step 3 at 30-80° C. for 5-10 hours to obtain the nickel nanotube array (c);

[0040] Step ...

Embodiment 1

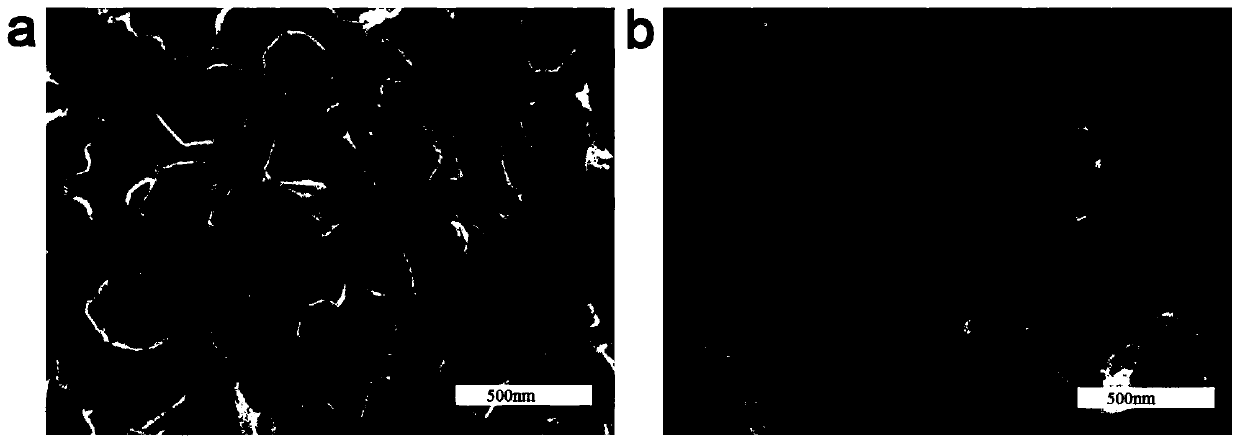

[0060] One, prepare nickel oxide-nickel-nickel oxide nanotube array according to the following method:

[0061] (1) Electrochemical deposition of nickel-copper alloy film on a clean nickel foil (2cm×2cm, 15μm thick), electrochemical deposition conditions: current density is -4.5mA cm -2 , the time is 10min, the solution contains 1M NiSO 4 , 0.05M CuSO 4 and 0.5M H 3 BO 3 (pH value is adjusted to be 4), the ratio of Ni:Cu:B is 20:1:10, uses two electrode system, and wherein nickel foil and platinum sheet are respectively working electrode and counter electrode;

[0062] (2) The alloy film obtained by electrochemical deposition was in the same solution at 0.5V (relative to Li + / Li) under dealloying, the time is 5min;

[0063] (3) Soak the nickel film after the dealloying that step (2) obtains in 1M hydrochloric acid solution for 15min, remove the surface oxide film, then clean it up with deionized water;

[0064] (4) heating the nickel film obtained in step (3) at 60° C. ...

Embodiment 2

[0081] Nickel oxide-nickel-nickel oxide nanotube arrays were prepared as follows:

[0082] (1) Electrochemical deposition of nickel-copper alloy film on a clean nickel foil (2cm×2cm, 15μm thick), electrochemical deposition conditions: current density is -1mA cm -2 , the time is 30min, the solution contains 5M NiSO 4 , 0.25M CuSO 4 and 2.5M H 3 BO 3 (pH value is adjusted to be 2), the ratio of Ni:Cu:B is 20:1:10, uses two electrode systems, and wherein nickel foil and platinum sheet are respectively working electrode and counter electrode;

[0083] (2) Dealloying the alloy film obtained by electrochemical deposition in the same solution at 1V (relative to Li+ / Li) for 3min;

[0084] (3) soak the nickel film after the dealloying that step (2) obtains in 0.5M hydrochloric acid solution for 20min, remove surface oxide film, then clean up with deionized water;

[0085](4) heating the nickel film obtained in step (3) at 30° C. for 10 h in a vacuum oven to obtain a nickel nanotub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com