Automated assembly line for electronic products

A technology for electronic products and production lines, applied in the direction of electrical components, electrical components, etc., can solve the problems of difficulty in controlling the pressure of electronic components or PCB boards, different sizes of PCB boards, and difficulty in supplying common materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

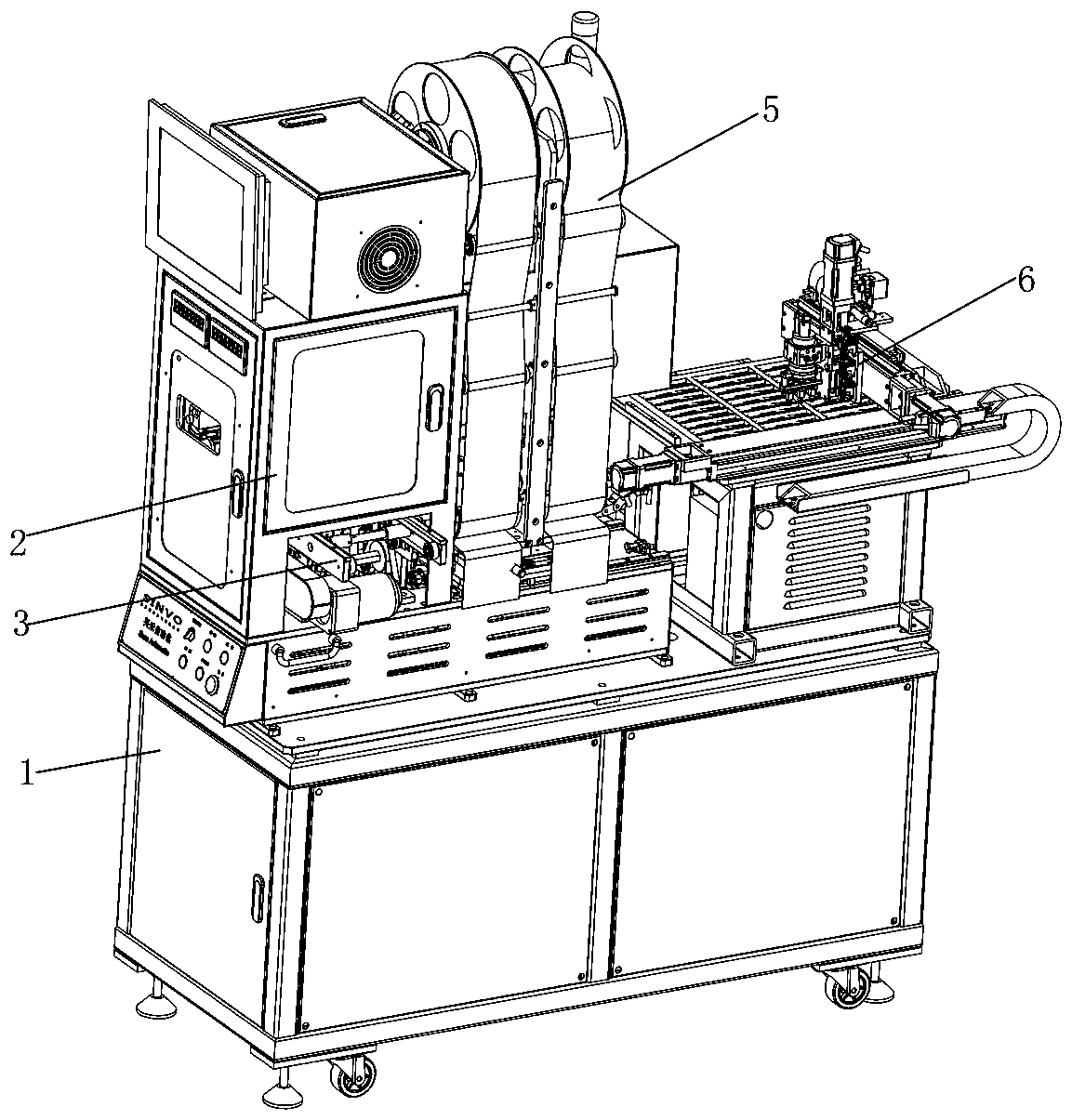

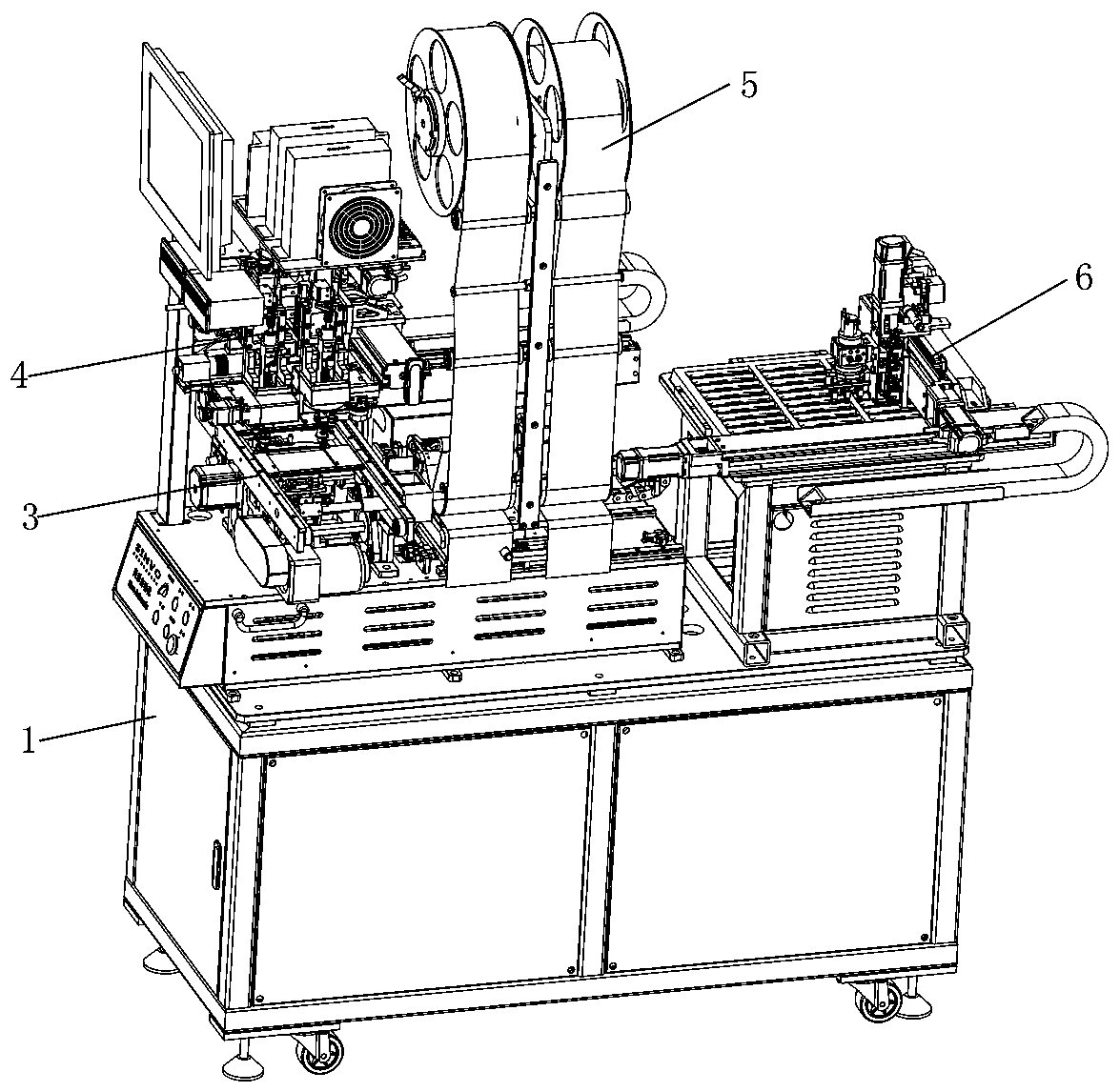

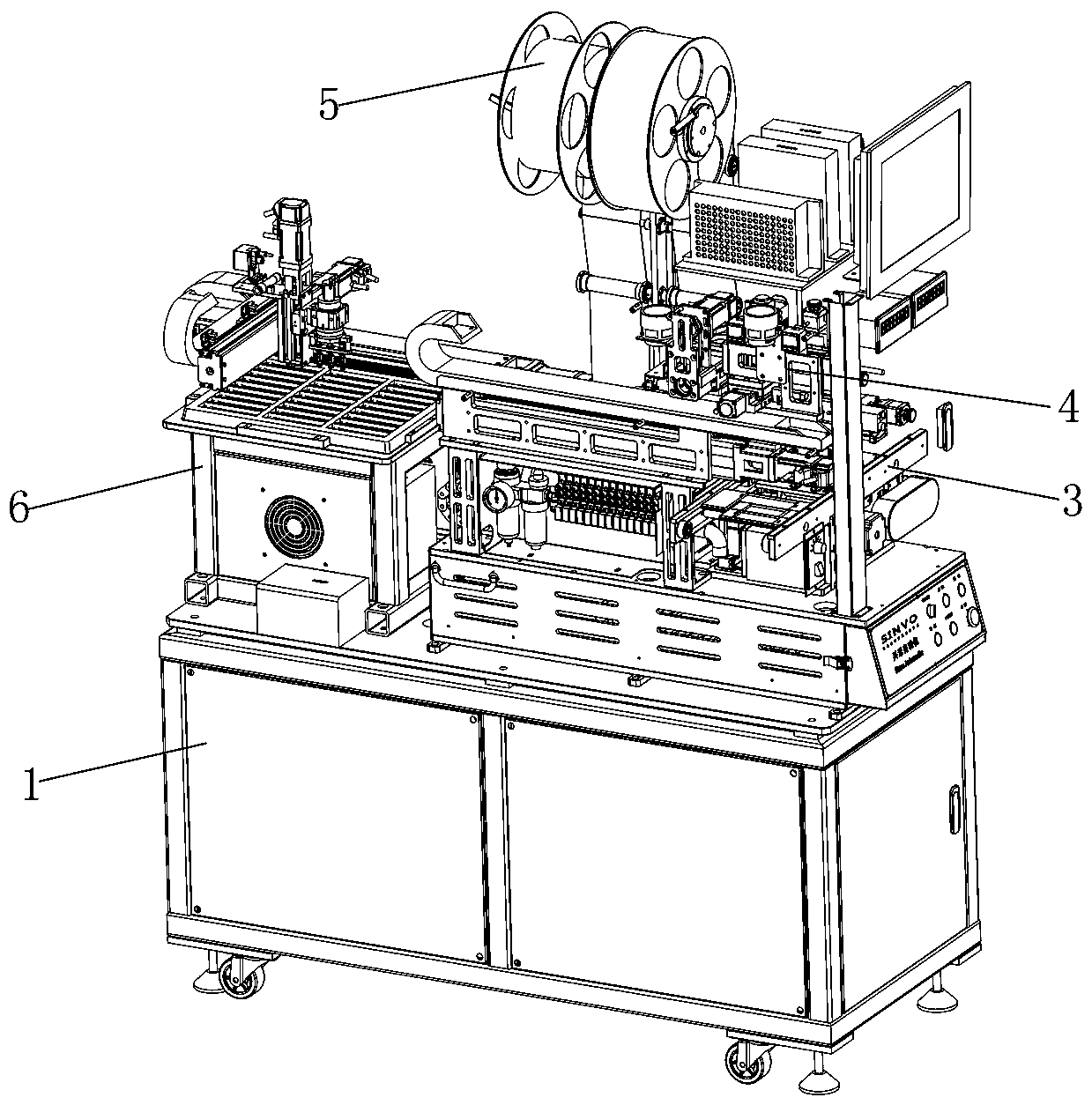

[0053] The present invention will be further described below in conjunction with accompanying drawing:

[0054] Such as Figure 1 to Figure 18 As shown, the technical solution adopted by the present invention is as follows: an automated assembly line for electronic products, including a product delivery mechanism 3, an assembly mechanism 4, a feeding mechanism 5, a feeding platform 6 and a buffer seat 7, wherein the above-mentioned product delivery mechanism 3 is arranged on the frame 1 along the front and rear directions, and an assembly station is set on the product transmission mechanism 3, and a positioning component and an adsorption component are arranged at the assembly station. The product 0 to be assembled is placed on the product transmission mechanism 3, and the After the transmission mechanism 3 is transferred from the previous processing station to the assembly station, it is positioned front and rear by the positioning component, and is fixed by adsorption compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com