Aluminum alloy building template and extrusion process

A construction formwork and aluminum alloy technology, which is applied in the direction of construction, building structure, formwork/formwork components, etc., can solve the problem of low density of pure aluminum, poor performance of aluminum alloy materials, tensile strength, yield strength and elongation. The effect and other issues, to achieve energy and cost savings, long-term use, improve the overall efficiency of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

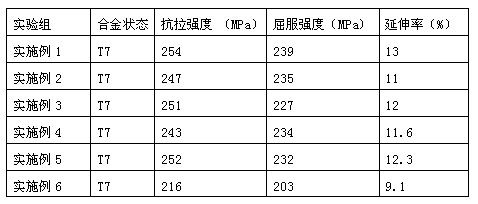

Examples

Embodiment 1

[0019] An aluminum alloy building template in this embodiment includes a template body, wherein the template body includes a template base material, a film layer above and below the template base material, and the material of the film layer is polyurethane hot-melt adhesive. There are four die holes with different specifications. There are flow channels outside the die holes, and there are paint layers on the upper film layer and the lower film layer. The material of the paint layer is corrosion-resistant coating.

[0020] The polyurethane hot melt adhesive in this embodiment is an adhesive containing polyisocyanate groups in the molecular chain, and the thickness of the film layer is 300 μm.

[0021] The extrusion process of aluminum alloy construction formwork of this embodiment is produced aluminum alloy, and extrusion process comprises the steps as follows: Make formwork main body; Put aluminum alloy into electric heating furnace and heat into metal flow and preheat formwor...

Embodiment 2

[0023] An aluminum alloy building template in this embodiment includes a template body, wherein the template body includes a template base material, a film layer above and below the template base material, and the material of the film layer is polyurethane hot-melt adhesive. There are four die holes with different specifications. There are flow channels outside the die holes, and there are paint layers on the upper film layer and the lower film layer. The material of the paint layer is corrosion-resistant coating.

[0024] The polyurethane hot melt adhesive in this embodiment is an adhesive containing polyisocyanate groups in the molecular chain, and the thickness of the film layer is 300 μm.

[0025] The aluminum alloy building formwork of this embodiment is an extrusion process for producing aluminum alloys. The extrusion process includes the following steps: making the formwork body, heating the aluminum alloy in an electric heating furnace to form a metal stream, and prehea...

Embodiment 3

[0028] An aluminum alloy building template in this embodiment includes a template body, wherein the template body includes a template base material, a film layer above and below the template base material, and the material of the film layer is polyurethane hot-melt adhesive. There are four die holes with different specifications. There are flow channels outside the die holes, and there are paint layers on the upper film layer and the lower film layer. The material of the paint layer is corrosion-resistant coating.

[0029] The polyurethane hot melt adhesive in this embodiment is an adhesive containing polyisocyanate groups in the molecular chain, and the thickness of the film layer is 300 μm.

[0030] The extrusion process of aluminum alloy construction formwork of this embodiment is produced aluminum alloy, and extrusion process comprises the steps as follows: make formwork main body, put aluminum alloy into electric heating furnace and heat into metal material flow and prehea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com