Shell opening and cube taking device of scallop cube taking machine and shell opening and cube taking technology of device

A technology for scallops and scallop skirts, which is applied to the field of shell-opening and dicing devices, can solve the problems of time-consuming, labor-intensive and efficient, affecting product flavor, and large volume, and achieves a good dicing effect, ingenious process design, and high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

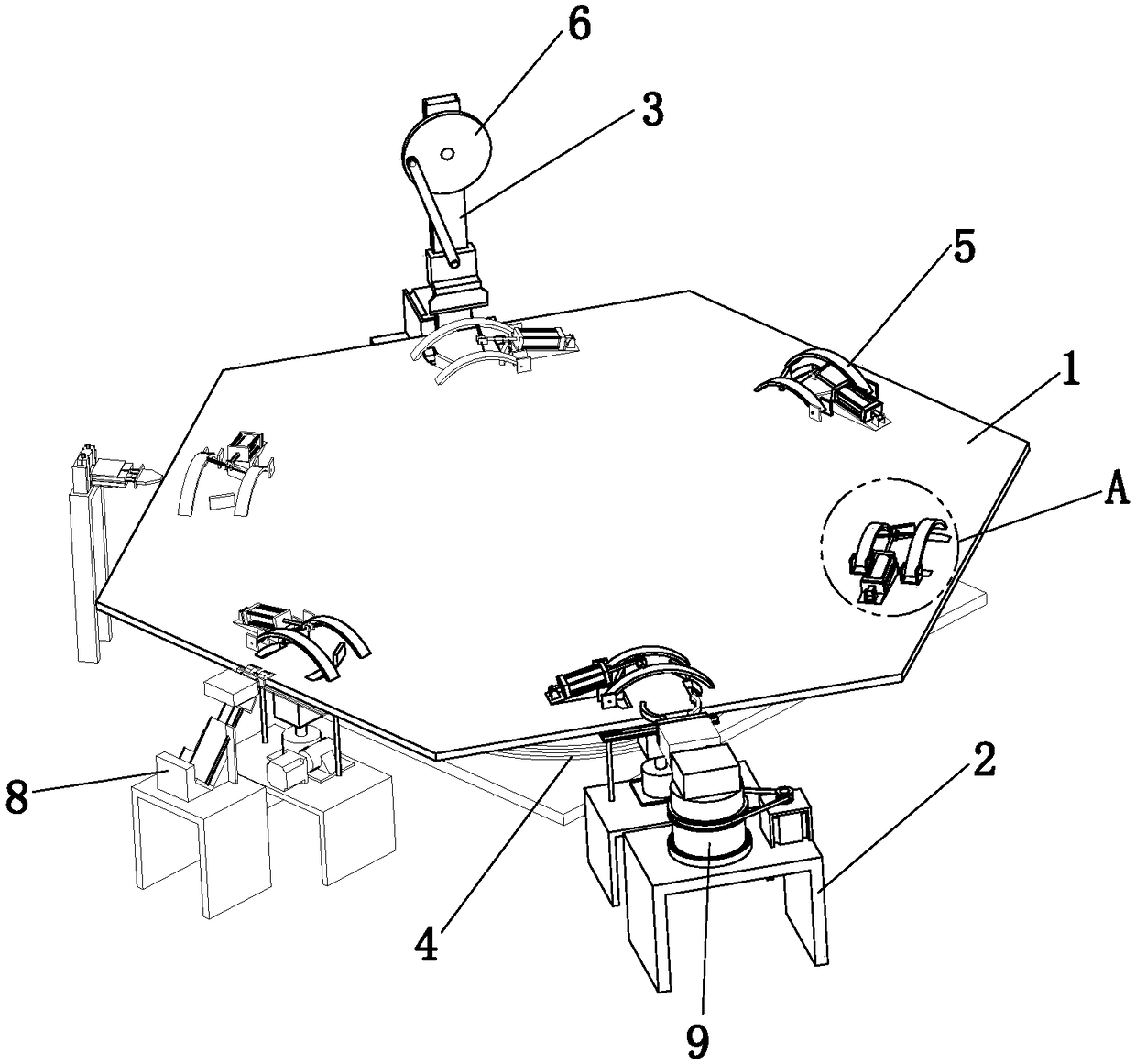

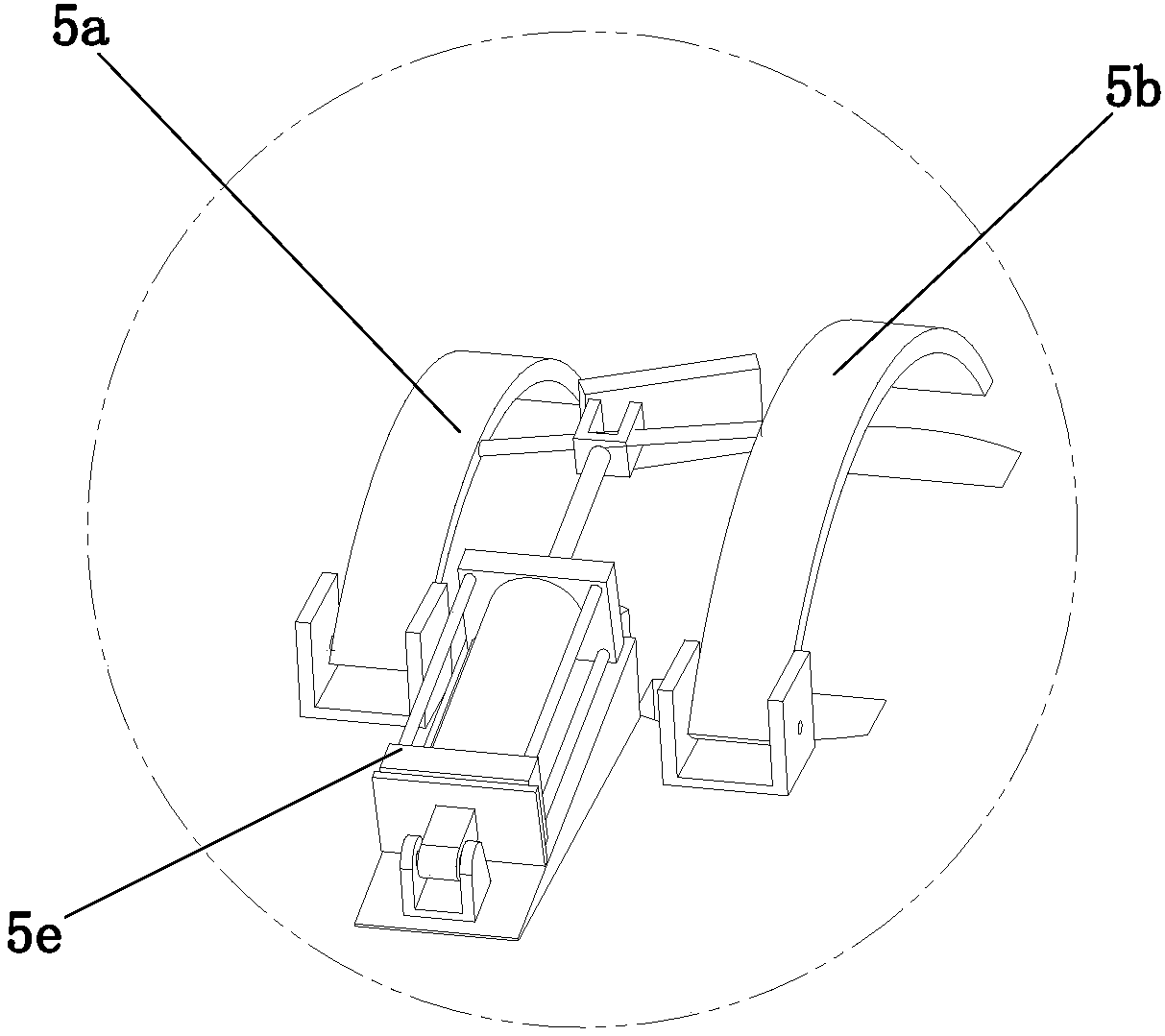

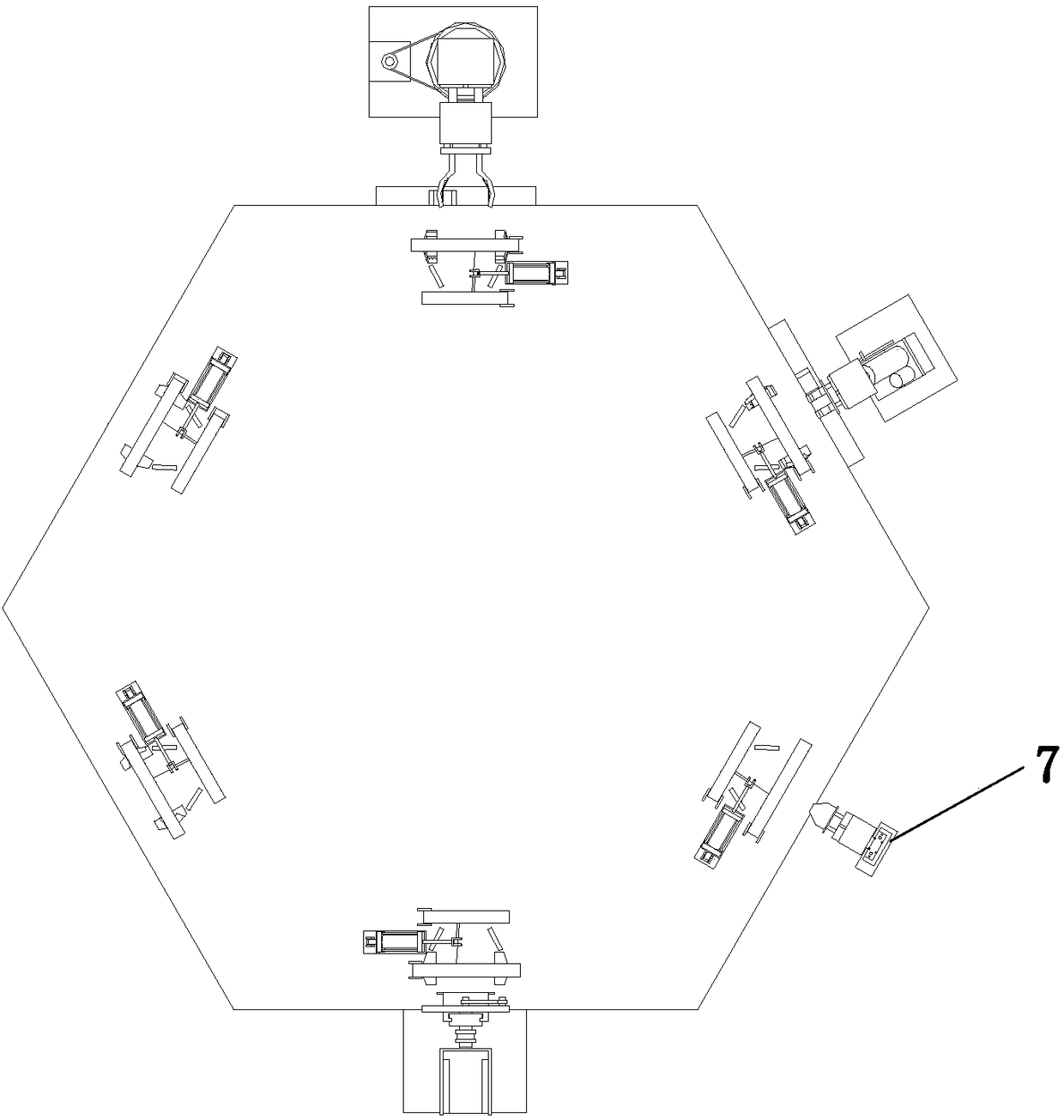

[0039] refer to Figure 1 to Figure 14 The shown scallop dicing machine includes a stepping turntable 1, a shell opening and dicing device 2 and a notch prying device 3, and the shell opening and dicing device 2 and the notch prying device 3 are all located on the side of the stepping turntable 1, The bottom of the stepping turntable 1 is provided with a rotating assembly 4 for driving the stepping turntable 1 to rotate, and the top of the stepping turntable 1 is provided with several limit assemblies 5 for limiting the scallops. All the limit assemblies 5 Arranged in sequence along the rotation direction of the stepping turntable 1 with equal angle differences, the notch prying device 3 includes a notch assembly 6 for cutting off the edge of the scallop opening and a tilting assembly 7 for tilting the upper shell of the scallop at a certain angle , the tilting assembly 7 is located between the shell picking device 2 and the incision assembly 6, the incision assembly 6 include...

Embodiment 2

[0061] The shelling and dicing process of the scallop dicing device of the scallop dicing machine described in embodiment 1 may further comprise the steps:

[0062] Step 1, stepping the turntable 1 to rotate the scallop to the side of the shell opening assembly 8, the screw elevator 10c2 works to lift the installation box 10c3 to a certain height, so that the first arc-shaped plate 10a5 and the second arc-shaped plate 10a7 reach through the slot The position where the lower shell of the scallop can be clamped, the self-locking motor 10b works to drive the first driving gear 10b1 to rotate, and the first driving gear 10b1 drives the first sliding plate 10a3 and the second sliding plate 10a4 to move in the direction of the first driving gear 10b1, and the first sliding plate 10a3 and the second slide plate 10a4 drive the first arc-shaped plate 10a5 and the second arc-shaped plate 10a7 to move toward the scallop and clamp the lower shell of the scallop, and the first pressing plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com