Rice-flavor oil-in-water type oil and fat composition and preparation method thereof

A technology of oil composition and oil-in-water type, which is applied in the production/processing of edible oil/fat, and can solve problems such as poor melting properties, greasy taste, and complicated procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

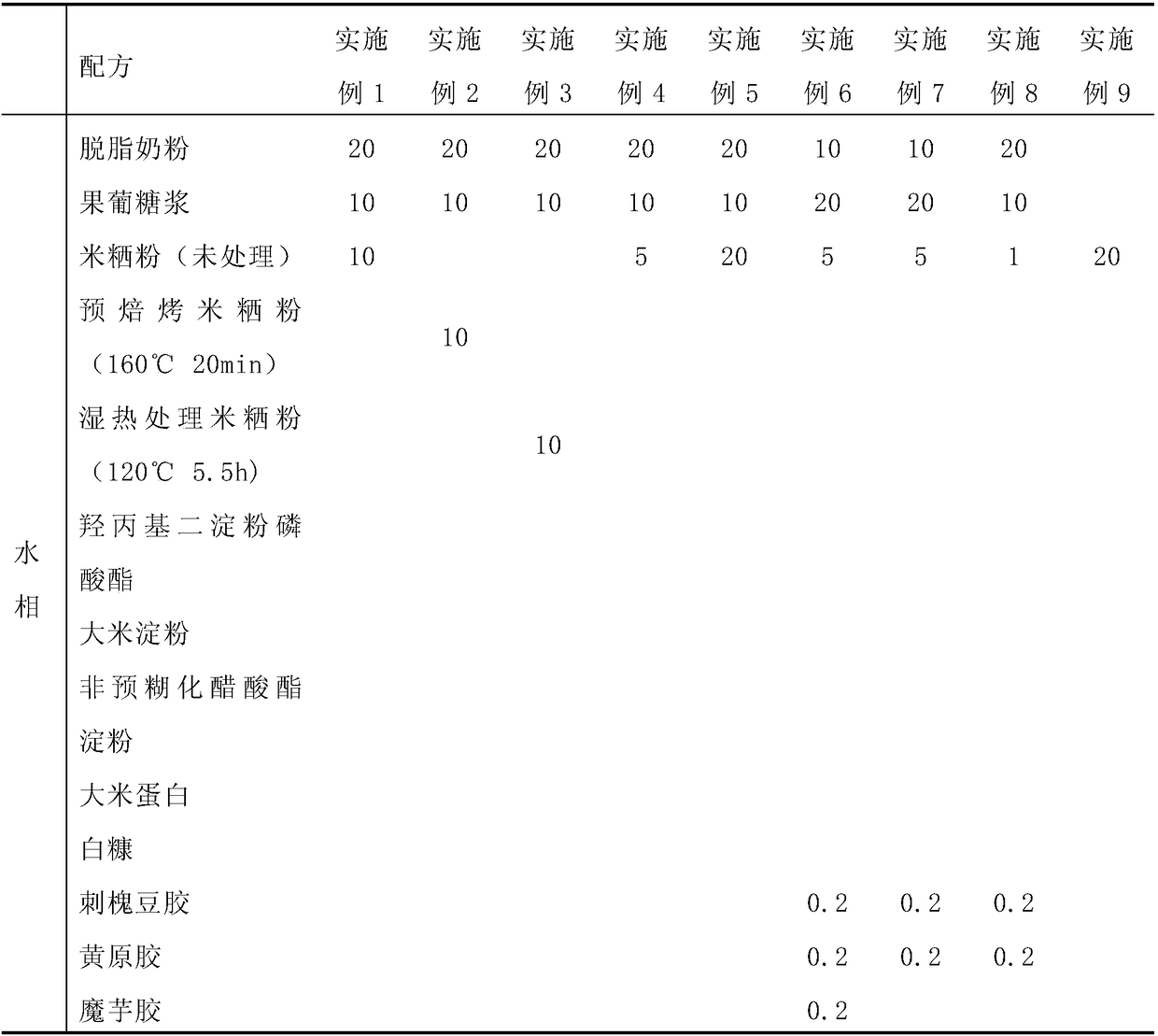

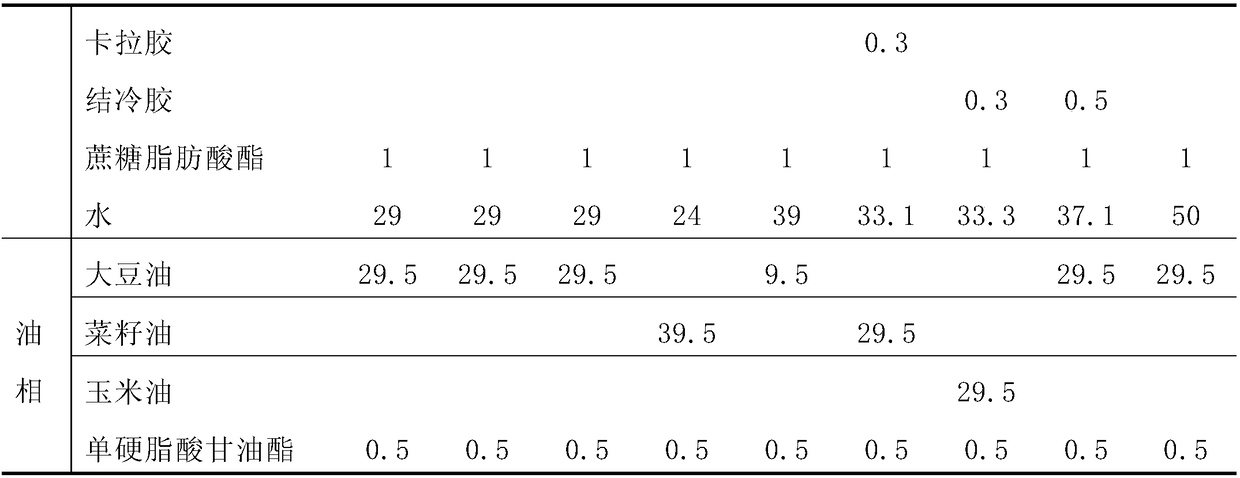

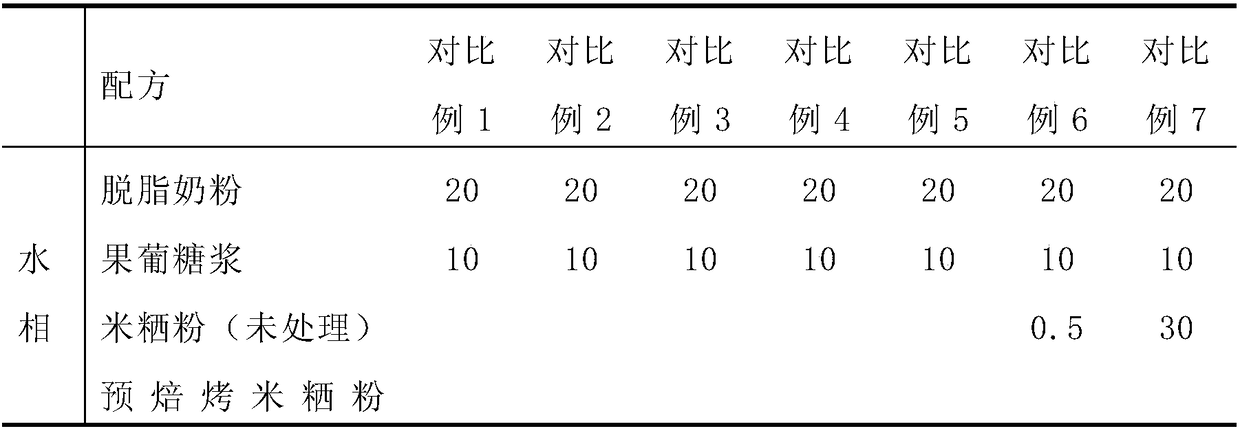

[0104] Embodiment 1-9: the preparation of oil composition of the present invention

[0105] The oil compositions of Examples 1-9 of the present invention were prepared according to the formula shown in Table 1 and the following steps.

[0106] Preparation of oil phase: Add emulsifier to liquid oil at 60°C, dissolve and mix well;

[0107] Water phase preparation: heat water to 50°C, add emulsifier to dissolve and mix evenly, add other ingredients in the water phase, stir evenly, then raise the temperature of the solution to 85°C, keep it for 30min, and cool down to 60°C;

[0108] Preparation of oil-in-water oil composition: Slowly pour the oil phase at 60°C into the water phase at 60°C, emulsify at 10,000rpm under high-speed shear for 5 minutes, and then refrigerate at 4-10°C for 12 hours to obtain Example 1 -9 oil composition.

[0109] Table 1: The fat composition formula of embodiment 1-9

[0110]

[0111]

[0112] Note: Rice flour (untreated) refers to rice flour w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com