Hot and spicy sauce and preparation technology thereof

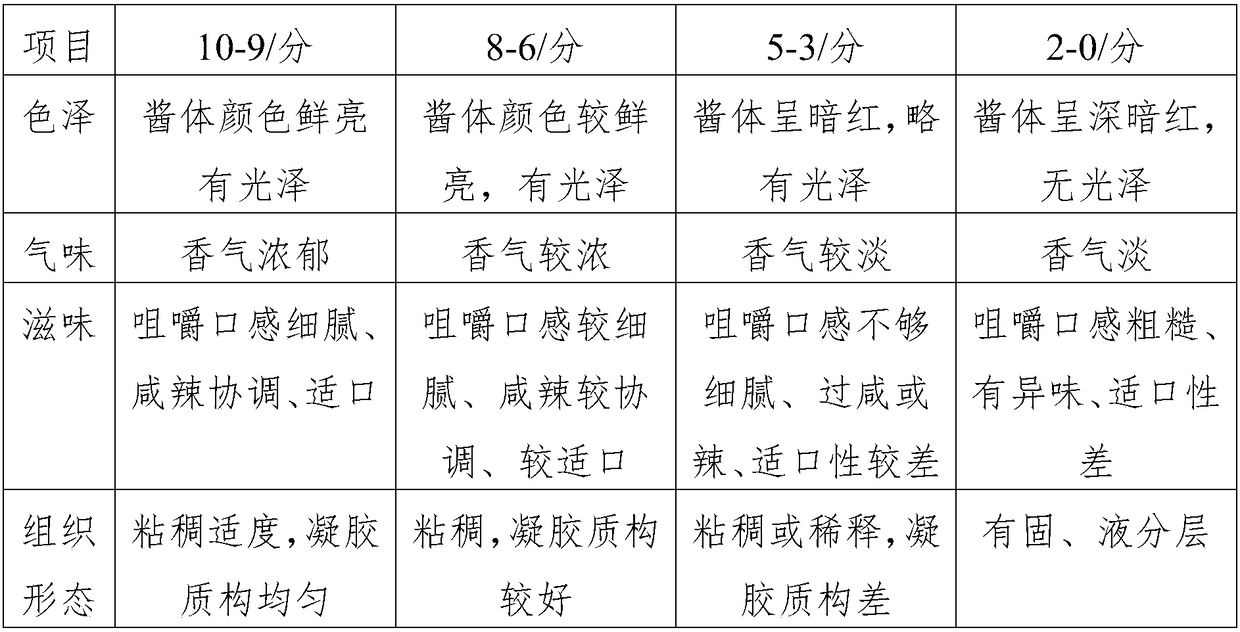

A production process and technology of spicy sauce, applied in the field of condiments, can solve the problems of insufficiency of nutrition and taste, and achieve the effects of fine and smooth taste, complete color and fragrance, and bright red and oily color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The spicy sauce of the present embodiment is made from the following raw materials in parts by weight: 2400 parts of rapeseed oil, 510 parts of peanut oil, 1050 parts of old ginger, 205 parts of sand ginger, 2400 parts of garlic, 1100 parts of rice pepper, 190 parts of onion, scallions 145 parts, 95 parts of scallion, 60 parts of tempeh, 480 parts of chili powder, 190 parts of white sesame, 55 parts of white pepper powder, 505 parts of glutinous rice, 40 parts of rock sugar, 60 parts of white sugar, 30 parts of strong liquor, 48 parts of salt, chicken essence 48 servings, 32 servings of monosodium glutamate, 45 servings of mature vinegar, 290 servings of light soy sauce, 95 servings of dark soy sauce, 35 servings of pepper oil, 490 servings of dried chili noodles, and 495 servings of dried wild small sea fish.

[0027] The preparation technology of above-mentioned sweet and spicy sauce, comprises the following steps:

[0028] 1) Preparation of raw materials: Weigh the r...

Embodiment 2

[0031]The spicy sauce of this embodiment is made from the following raw materials in parts by weight: 2600 parts of rapeseed oil, 450 parts of peanut oil, 980 parts of old ginger, 210 parts of sand ginger, 2450 parts of garlic, 1050 parts of rice pepper, 210 parts of onion, scallions 135 parts, scallion white 98 parts, tempeh 40 parts, chili powder 495 parts, white sesame seeds 210 parts, white pepper powder 45 parts, glutinous rice 490 parts, rock sugar 55 parts, white sugar 50 parts, high liquor 32 parts, salt 52 parts, chicken essence 50 parts, 28 parts of monosodium glutamate, 52 parts of old mature vinegar, 310 parts of light soy sauce, 105 parts of dark soy sauce, 25 parts of pepper oil, 505 parts of dried chili noodles, and 480 parts of dried wild shrimp.

[0032] The preparation technology of above-mentioned sweet and spicy sauce, comprises the following steps:

[0033] 1) Preparation of raw materials: Weigh the raw materials in corresponding parts by weight, wash the ...

Embodiment 3

[0036] The spicy sauce of this embodiment is made from the following raw materials in parts by weight: 2500 parts of rapeseed oil, 500 parts of peanut oil, 1000 parts of old ginger, 200 parts of sand ginger, 2500 parts of garlic, 1000 parts of rice pepper, 200 parts of onion, scallions 150 parts, 100 parts white onion, 50 parts tempeh, 500 parts chili powder, 200 parts white sesame, 50 parts white pepper powder, 500 parts glutinous rice, 50 parts rock sugar, 50 parts white sugar, 30 parts high-grade liquor, 50 parts salt, chicken essence 50 parts, 30 parts of monosodium glutamate, 50 parts of old mature vinegar, 300 parts of light soy sauce, 100 parts of dark soy sauce, 30 parts of pepper oil, 500 parts of dried chili noodles, and 500 parts of dried wild small sea fish.

[0037] The preparation technology of above-mentioned sweet and spicy sauce, comprises the following steps:

[0038] 1) Preparation of raw materials: Weigh the raw materials in corresponding parts by weight, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com