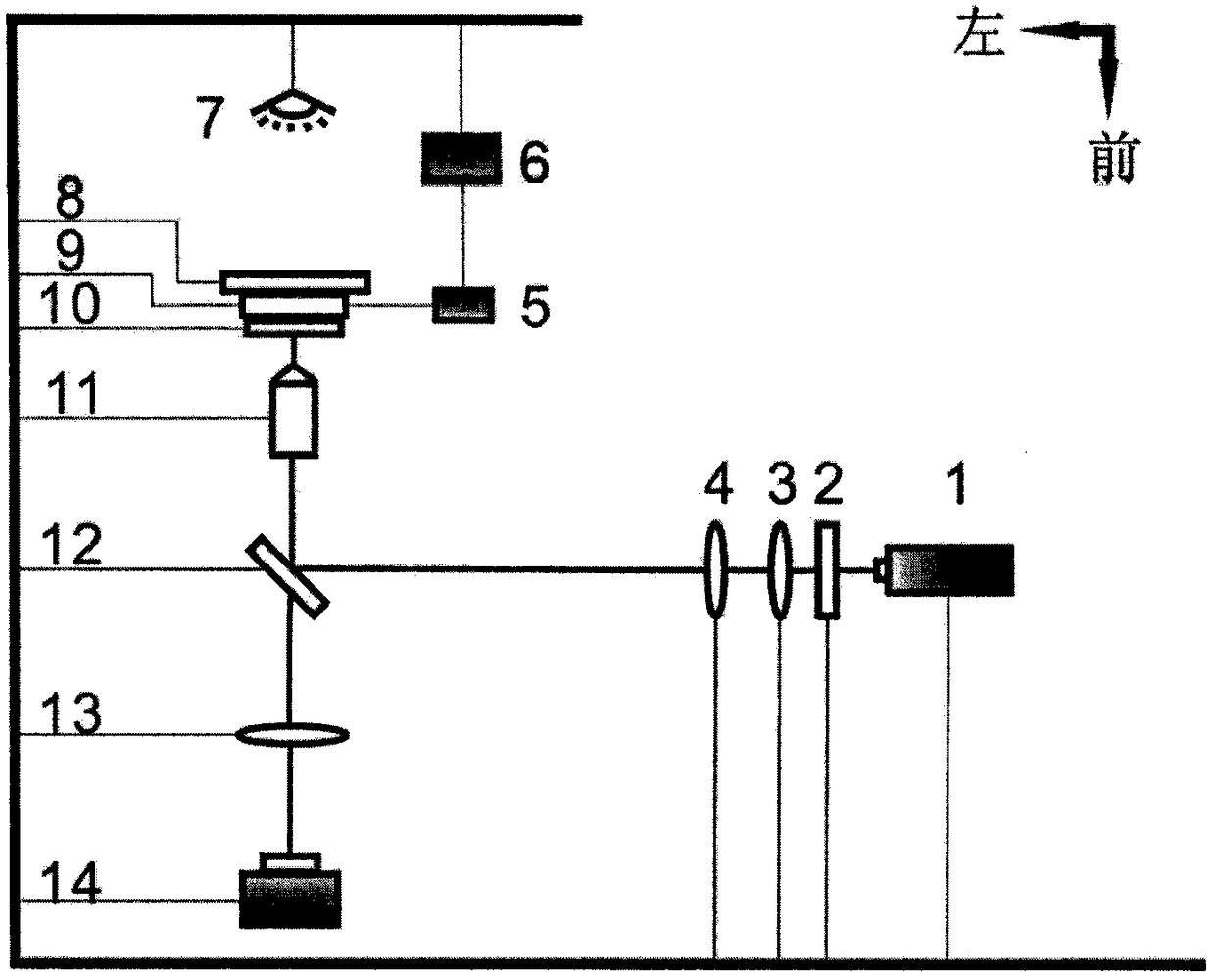

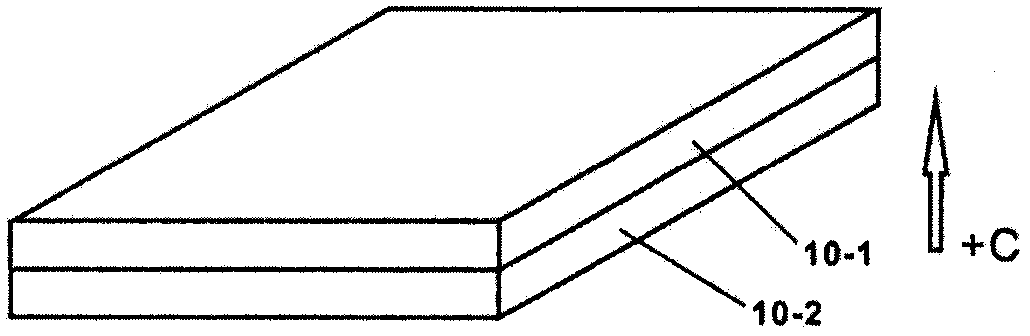

Real-time controllable micro-droplet reciprocated conveying device and method based on lithium niobate sandwich structure chip

A sandwich structure and micro-droplet technology, applied in chemical instruments and methods, laboratory equipment, fluid controllers, etc., can solve problems such as high cost, complex processing technology, and turbulent droplet environment, and achieve controllable distance and low cost. The effect of low and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

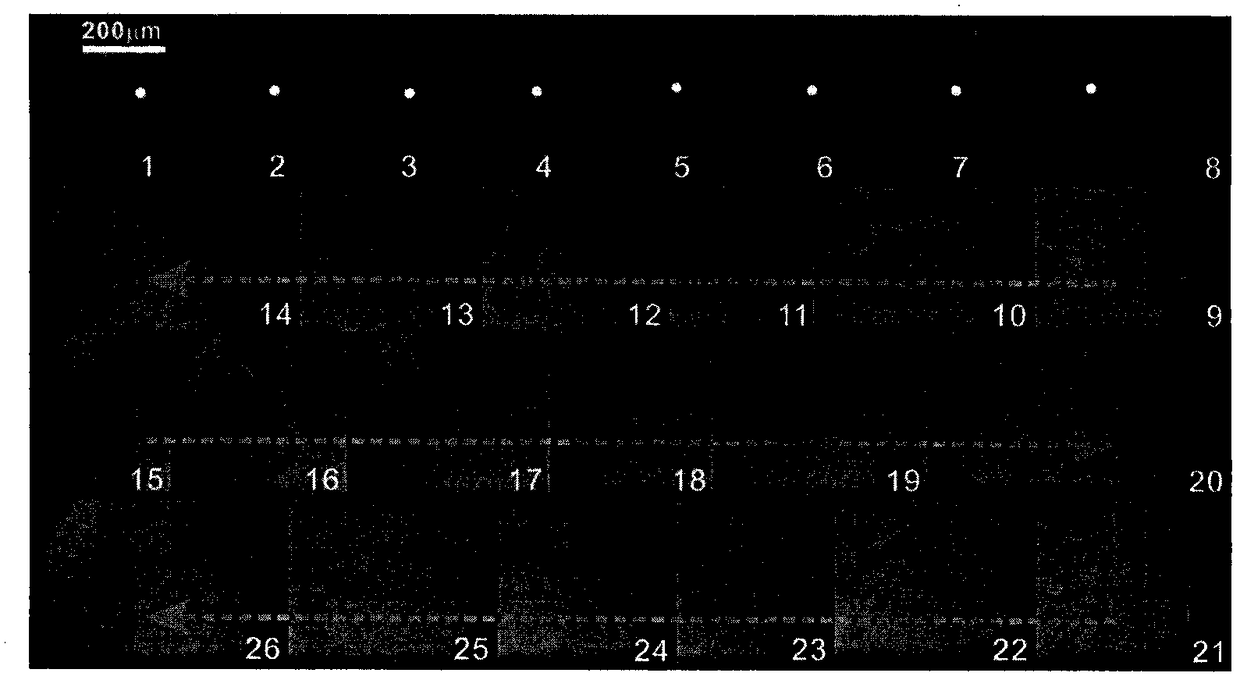

[0029] Using a 473nm laser, the laser power is 10mW, the background light source is a halogen lamp, the magnification of the focusing objective lens is 16 times, and the micro-droplet with a volume of 0.05μL to be transported is introduced into the lithium niobate sandwich structure chip, and the intelligent digital display temperature is used. The controller heats the semiconductor cooling sheet. When the temperature of the temperature controller panel shows 30.23°C, keep it warm for 5 minutes, open the electronic shutter, move the transparent fine-tuning three-dimensional translation stage, and make the laser spot sweep a line on the lithium niobate sandwich structure chip. A straight line with a length of 0.70mm is close to the micro-droplet. When the micro-droplet is attracted to the laser spot, the electronic shutter is closed to complete the reciprocating transport of the micro-droplet.

Embodiment 2

[0031] Using a 532nm laser, the laser power is 15mW, the background light source is a halogen lamp, and the magnification of the focusing objective lens is 16 times. The micro-droplet with a volume of 0.07μL to be transported is introduced into the lithium niobate sandwich structure chip, and the intelligent digital display temperature is used. The controller heats the semiconductor cooling sheet. When the temperature of the temperature controller panel shows 33.45°C, keep it warm for 5 minutes, open the electronic shutter, move the transparent fine-tuning three-dimensional translation stage, and make the laser spot sweep a line on the lithium niobate sandwich structure chip. A straight line with a length of 0.25mm is close to the micro-droplet. When the micro-droplet is attracted to the laser spot, the electronic shutter is closed to complete the reciprocating transport of the micro-droplet.

Embodiment 3

[0033] Using a 405nm laser, the laser power is 18mW, the background light source is a halogen lamp, the magnification of the focusing objective lens is 16 times, and the micro-droplet with a volume of 0.08 μL to be transported is introduced into the lithium niobate sandwich structure chip, and the intelligent digital temperature display is used. The controller heats the semiconductor cooling chip. When the temperature controller panel temperature shows 38.65°C, keep it warm for 5 minutes, open the electronic shutter, move the transparent fine-tuning three-dimensional translation stage, and make the laser spot sweep a line on the lithium niobate sandwich structure chip. A straight line with a length of 0.30mm is close to the micro-droplet. When the micro-droplet is attracted to the laser spot, the electronic shutter is closed to complete the reciprocating transport of the micro-droplet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com