System for cooperatively treating kitchen garbage by utilizing cement kiln and treatment method thereof

A technology for co-processing and kitchen waste, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of easily destroying the soil ecological environment, hidden safety hazards, and high energy consumption, and improve resource utilization. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

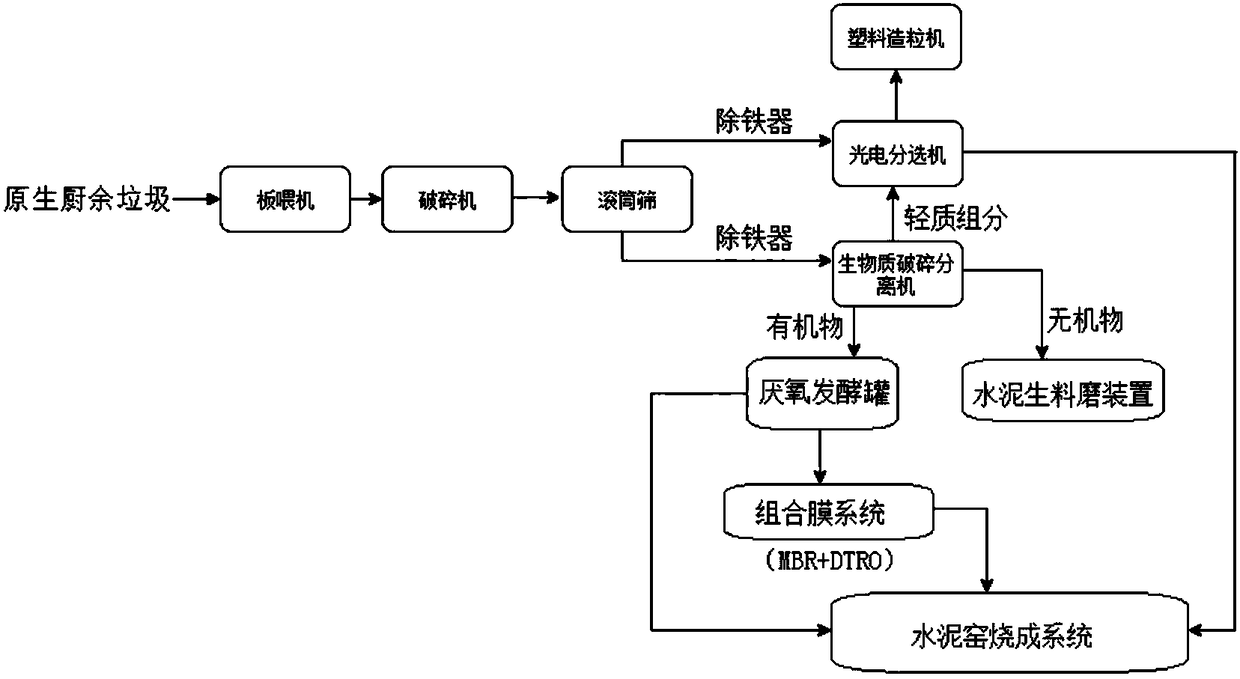

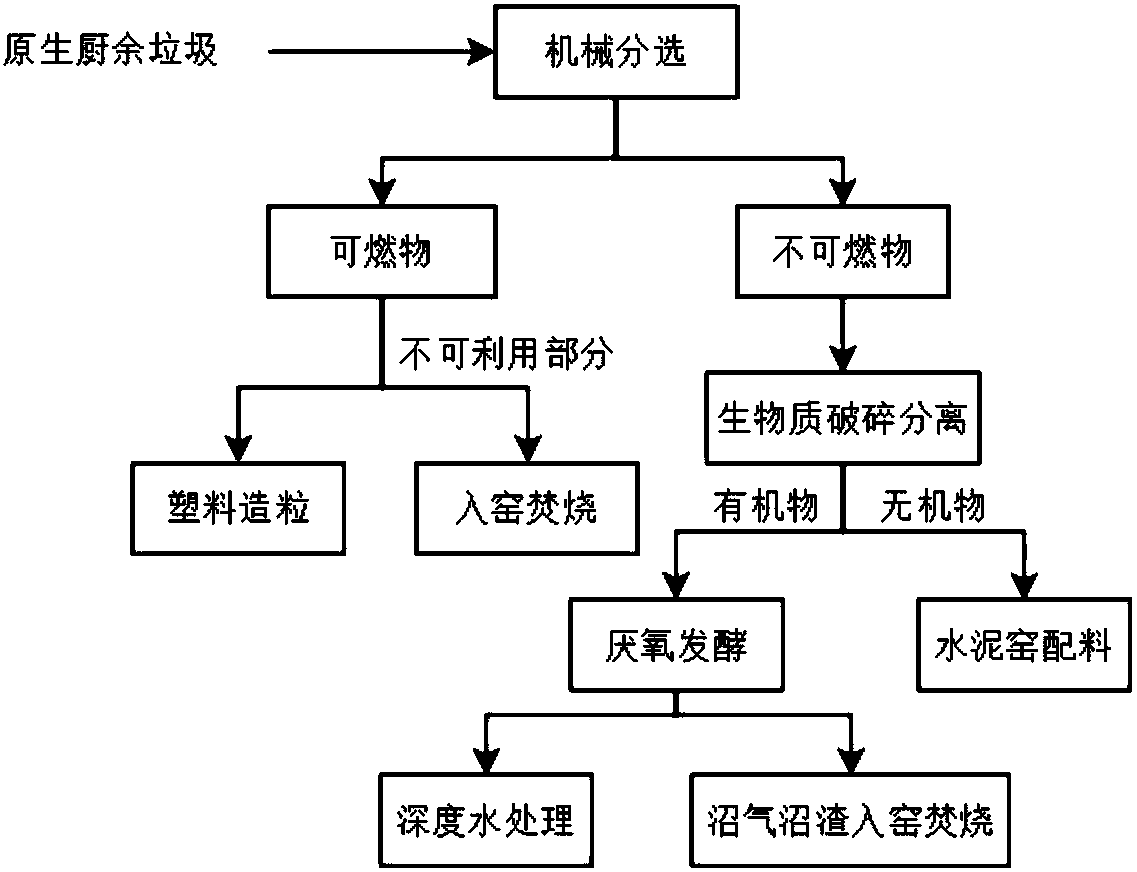

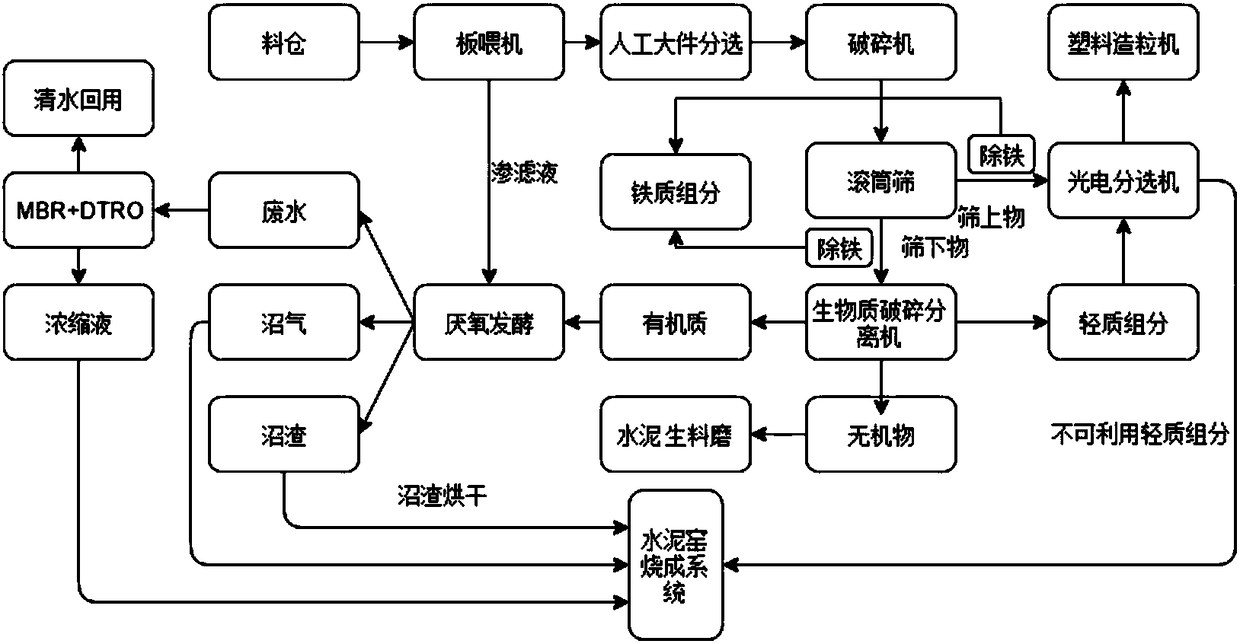

[0020] Such as Figure 1~3 As shown, the present invention uses a cement kiln to co-process food waste system, including a pretreatment device, an advanced treatment device, a biological treatment device and a cement kiln firing system; wherein, the pretreatment device includes a plate feeder, a crusher and a cement kiln firing system connected in sequence. Trommel screen; advanced treatment device includes photoelectric separator and biomass crushing separator; also includes plastic granulator and cement raw material mill device; biological treatment device includes sequentially connected anaerobic fermentation tank and combined membrane system; combined membrane system It is composed of MBR membrane bioreactor + DTRO reverse osmosis device; the output port of the trommel screen is respectively connected to the photoe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com