Preparation method of TMCP double phase stainless steel composite board for ship

A technology of duplex stainless steel and clad plate, used in manufacturing tools, welding equipment, non-electric welding equipment, etc., can solve the problems of cumbersome process, influence of rolling power, etc., and achieve high market benefits, good corrosion resistance, carbon equivalent low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

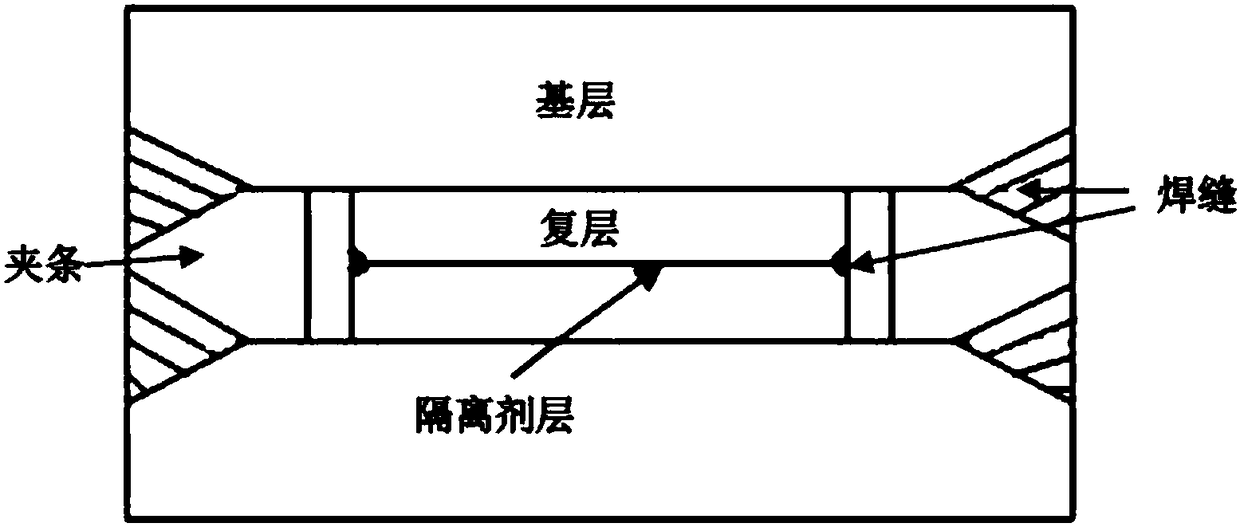

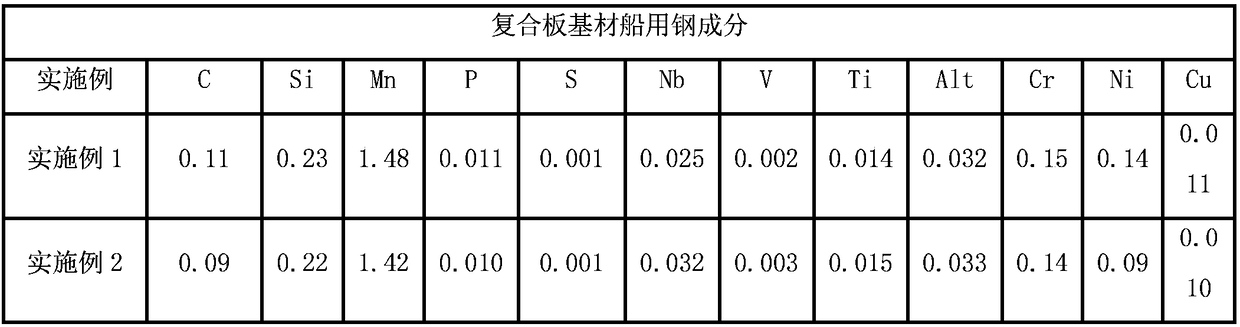

[0027] In this example, DH36 steel with a base material thickness of 94mm is selected. The chemical composition is shown in Table 1. The composite material blank is S22053 duplex stainless steel with a thickness of 16mm, and the rolled finished product is S22053+DH36 composite plate with a thickness of 4+24mm.

[0028] One of the surfaces of the two DH36 substrate blanks and the two S22053 composite blanks was ground to expose the fresh metal completely. Apply a release agent to the unpolished surface of the composite material, and dry the release agent. Spot-weld and fix the seal on the periphery of one of the base materials that has been polished; put the non-composite surfaces of the two composite materials together and place them in the groove surrounded by the seal strips, and place the composite surface of the other base material downwards, cover On the top of the two composite materials, at the same time ensure that the four sides of the upper and lower base materials a...

Embodiment 2

[0032]In this example, DH36 steel with a base material thickness of 58.5mm is selected. The chemical composition is shown in Table 1. The composite material blank is S22053 duplex stainless steel with a thickness of 16mm, and the rolled finished product is S22053+DH36 composite plate with a thickness of 3.2+12mm.

[0033] One of the surfaces of the two DH36 substrate blanks and the two S22053 composite blanks was ground to expose the fresh metal completely. Apply a release agent to the unpolished surface of the composite material, and dry the release agent. Spot-weld and fix the seal on the periphery of one of the base materials that has been polished; put the non-composite surfaces of the two composite materials together and place them in the groove surrounded by the seal strips, and place the composite surface of the other base material downwards, cover On the top of the two composite materials, at the same time ensure that the four sides of the upper and lower base material...

Embodiment 3

[0036] In this example, DH36 steel with a base material thickness of 118mm is selected. The chemical composition is shown in Table 1. The composite material blank is S22053 duplex stainless steel with a thickness of 20mm, and the rolled finished product is S22053+DH36 composite plate with a thickness of 5.0+30mm.

[0037] One of the surfaces of the two DH36 substrate blanks and the two S22053 composite blanks was ground to expose the fresh metal completely. Apply a release agent to the unpolished surface of the composite material, and dry the release agent. Spot-weld and fix the seal on the periphery of one of the base materials that has been polished; put the non-composite surfaces of the two composite materials together and place them in the groove surrounded by the seal strips, and place the composite surface of the other base material downwards, cover On the top of the two composite materials, at the same time ensure that the four sides of the upper and lower base material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com