3D printing stretched yarn, processing method and application

A 3D printing and 3D printer technology, applied in the fields of processing, auxetic yarn structure, and textile science, can solve the problems that are difficult to meet the requirements of functional textiles and difficult to be favored by consumers, and achieve good controllability and large adjustability , Good stretching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Example 1 Preparation of PLA concave hexagonal auxetic yarn

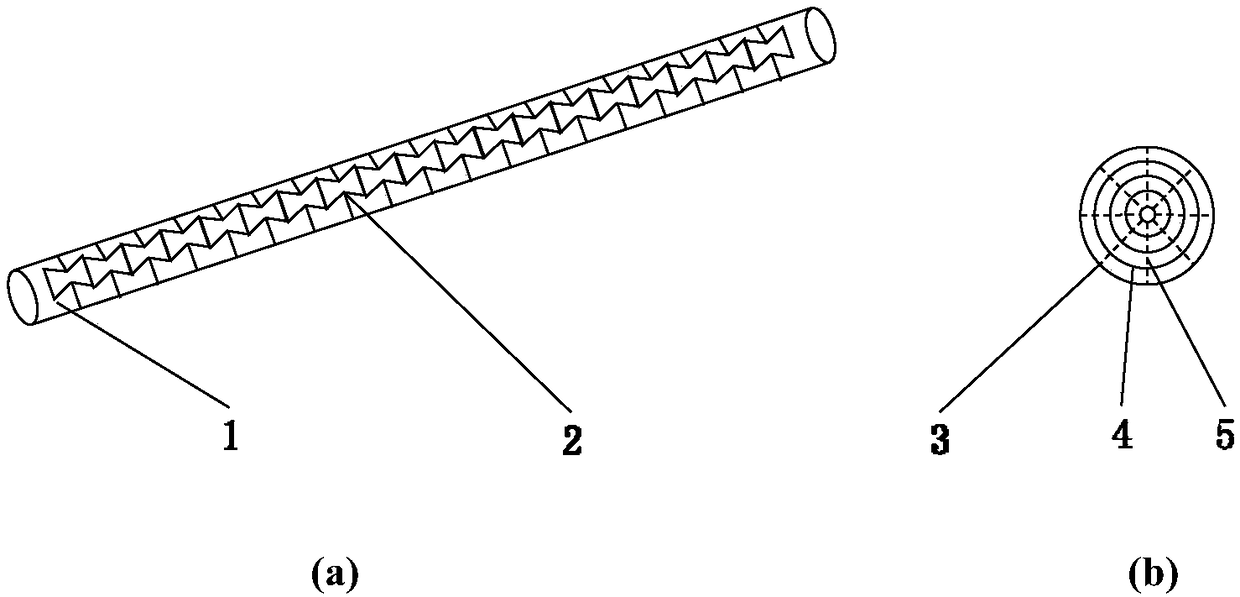

[0063] Such as figure 1 The 3D printed auxetic yarn 1 shown in (a) includes a multi-layer structure formed by 3D printing, the surface of each layer contains an auxetic geometric structure 2, and adjacent layers are connected to each other. The multi-layer structure is composed of a plurality of cylindrical layers arranged in sequence from the inside to the outside. The number of layers contained in the 3D printed auxetic yarn 1 and the spacing between each layer can be adjusted within the diameter range of the yarn, and the surface porosity of the yarn can be controlled. The layers of the 3D printed auxetic yarn 1 are connected by the connection points printed by the direct molding process (such as figure 1 (b) shown).

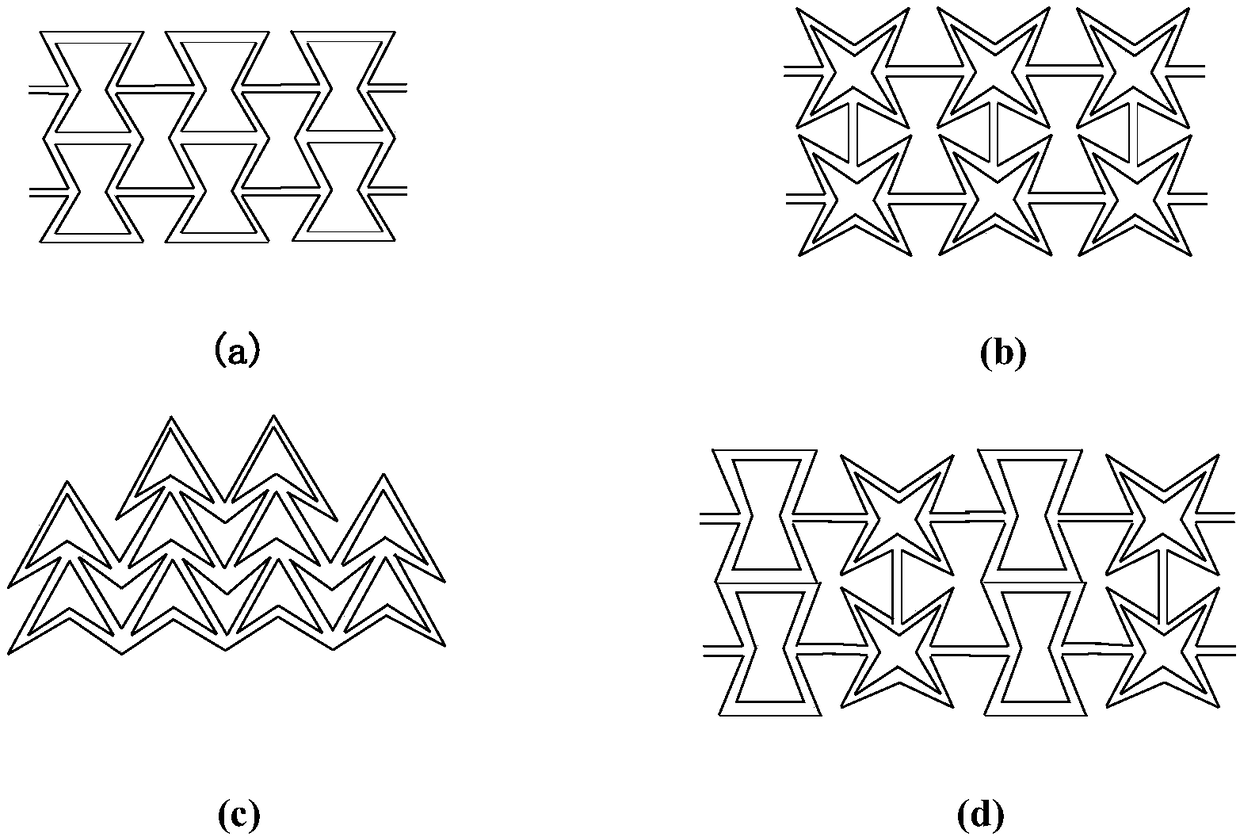

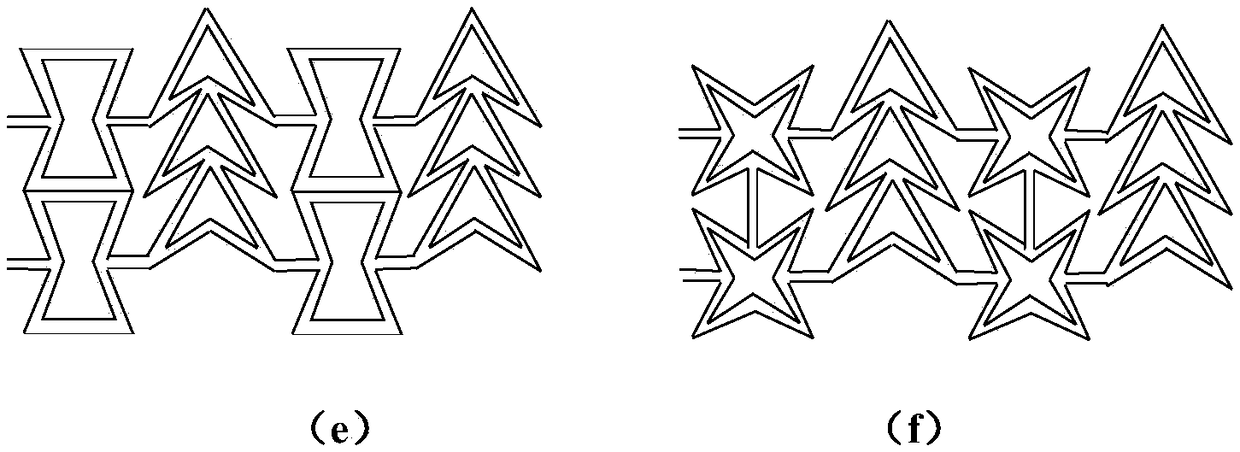

[0064] The auxetic geometric unit that produces the auxetic effect on the surface of the auxetic yarn is a concave hexagon, such as figure 2 As shown in (a), the printing material is PL...

Embodiment 2

[0067] Embodiment 2 Preparation of PLA star-shaped auxetic yarn

[0068] Similar to the 3D printing auxetic yarn of Example 1, the difference is that the multi-layer structure is composed of a plurality of involute cylindrical layers sequentially arranged from the inside to the outside. The auxetic geometric unit that produces the auxetic effect on the surface of the auxetic yarn is star-shaped, such as figure 2 As shown in (b), the printing material is PLA, and the molding method is fusion deposition, which is formed by stacking and stacking involute cylinders.

[0069] The above-mentioned 3D printing auxetic yarn processing method is: use CAD design software to design a three-dimensional data model of the yarn with a star-shaped auxetic structure, ensure that the designed model size matches the actual yarn magnitude, and then the designed model Export it to a common format, use the slicing software of the 3D printer to slice the above-mentioned design model, obtain a slice...

Embodiment 3

[0071] Example 3 Preparation of Photosensitive Resin Double Arrowhead Auxetic Yarn

[0072] Similar to the 3D printed auxetic yarn in Example 1, the difference is that the auxetic geometric unit that produces the auxetic effect on the surface of the auxetic yarn is a double arrow shape, such as figure 2 As shown in (c), the printing material is photosensitive resin, and the molding method is light curing, which is formed by stacking and stacking concentric cylinders.

[0073]The above-mentioned 3D printing auxetic yarn processing method is as follows: use CAD design software to design a three-dimensional data model of the yarn with a double arrow-shaped auxetic structure, ensure that the designed model size matches the actual yarn order of magnitude, and then print the designed The model is exported to a common format, and the above-mentioned design model is sliced using the slicing software of the 3D printer to obtain a sliced data model that can be printed on the 3D pri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com