Traveling mechanism based on module structure and assembling method

A technology of walking mechanism and modular structure, which is applied in the direction of lifting device, storage device, transportation and packaging, etc. It can solve the problems of difficult travel wheel bearings, inconvenient operation, poor installation accuracy, etc., and achieves reduced processing costs and reduced processing difficulty , The effect of high installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

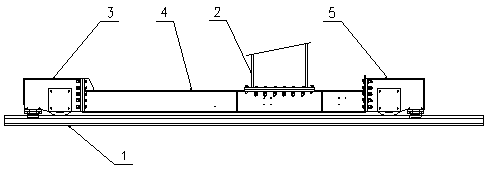

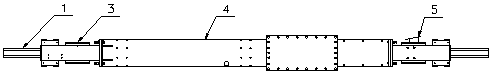

[0021] Such as figure 1 , figure 2 Shown, a kind of walking mechanism based on modular structure of the present invention comprises front wheel box 3, bottom support beam 4 and rear wheel box 5; Front wheel box 3, bottom support beam 4, rear wheel box 5 are respectively There are connecting flanges. The front wheel box 3 and the rear wheel box 5 are assembled separately at first, and then connected to the bottom support beam 4 with bolts after the respective assembly is completed, and the flange surfaces are closely attached to the rear front wheel box 3. , the bottom support beam 4, and the rear wheel box 5 become a whole, and after adjustment, the front wheel box 3, the bottom support beam 4, and the rear wheel box 5 can be realized on the same reference line, so that the overall welding accuracy error is difficult to avoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com