Electrolytic cells for industrial wastewater treatment

A technology of industrial wastewater and electrolytic cells, applied in the field of electrolytic cells, can solve the problems of troublesome disassembly or replacement, bulky cell body, and good treatment effect, and achieve the effects of convenient disassembly, high electrolysis efficiency, and simple connection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the solution of the utility model, the technical solution in the embodiment of the utility model will be clearly and completely described below in conjunction with the drawings in the embodiment of the utility model.

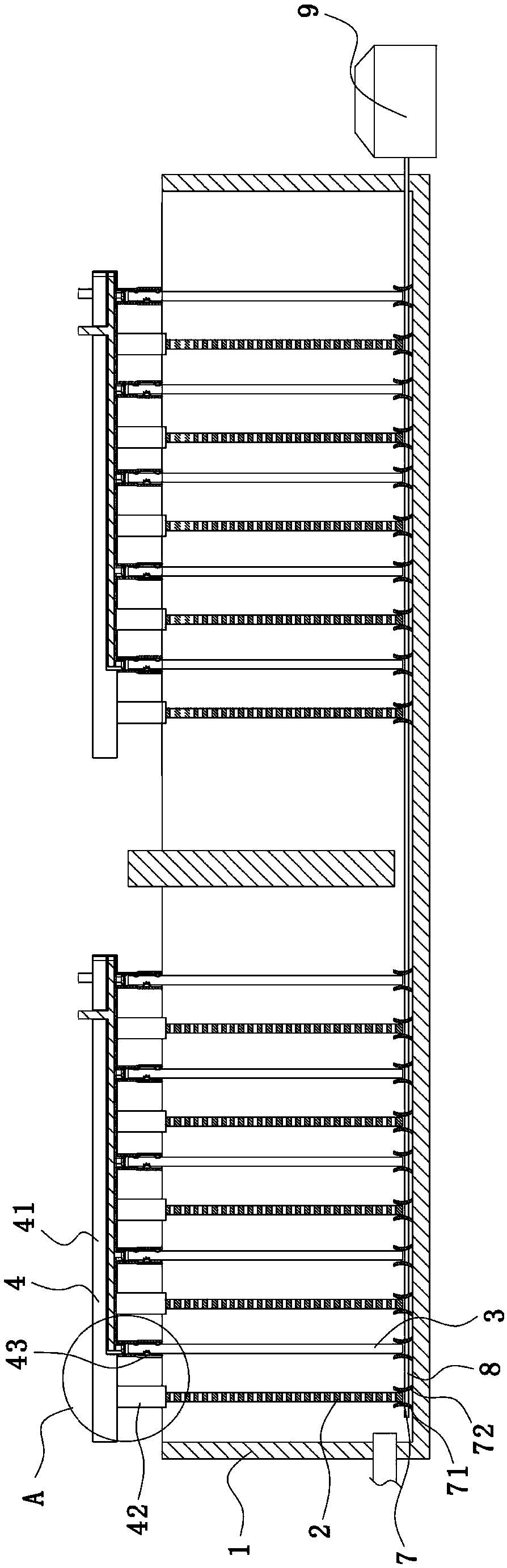

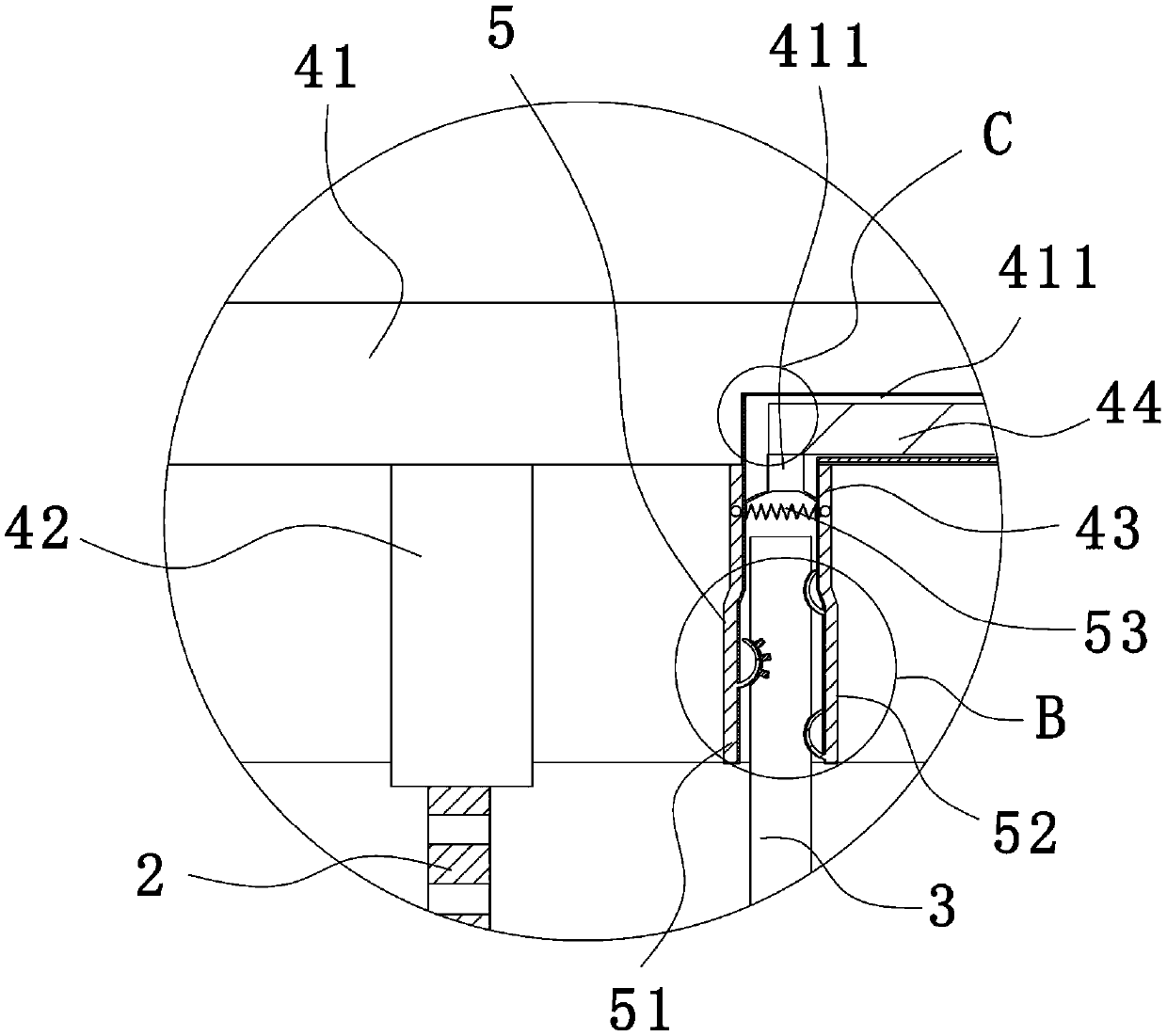

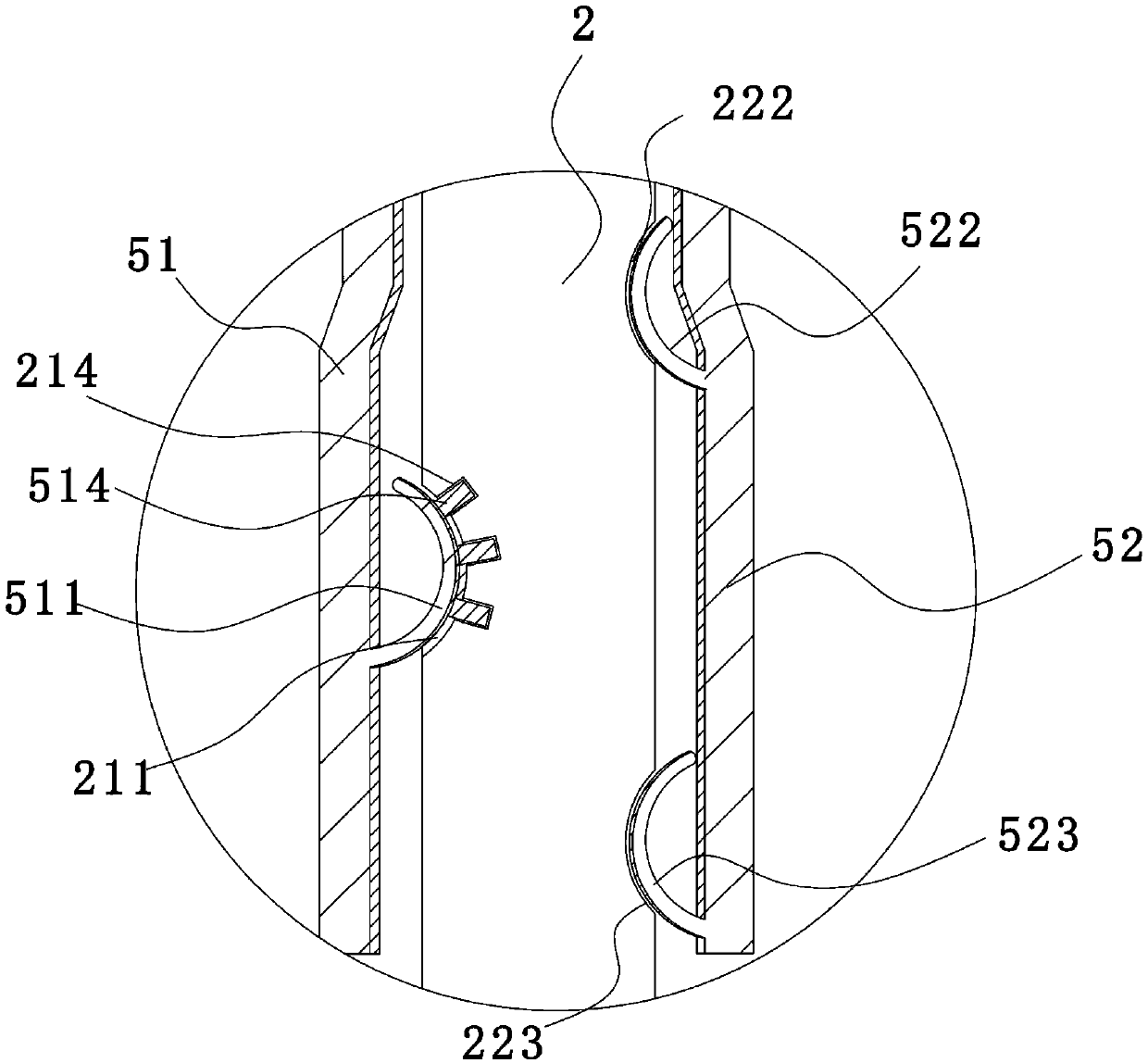

[0023] Such as Figure 1-4 As shown, an electrolytic cell for industrial wastewater treatment includes a cell body 1, a cathode part 2, an anode part 3 and a connecting part 4, wherein the cell body 1 is a square pool with a ceramic layer on the inner wall, and the cell body 1 is provided with four electrolytic components composed of the cathode part 2, the anode part 3 and the power supply 6, the cathode part 1 is a steel plate, and the anode part 3 is made of composite intermediate titanium-based lead dioxide material The titanium anode mesh made, the anode piece 3 and the cathode piece 2 are spaced apart from each other, that is, the anode piece 3 and the cathode piece 2 are adjacent to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com