Oil-well low-liquid-producing high-water-containing oil-water-two-phase-flow flow measuring method

A flow measurement, water oil and water technology, applied in the direction of measurement, earthwork drilling, wellbore/well components, etc., to achieve the effects of improving water holdup measurement resolution, sensitive capture, and increasing current density intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

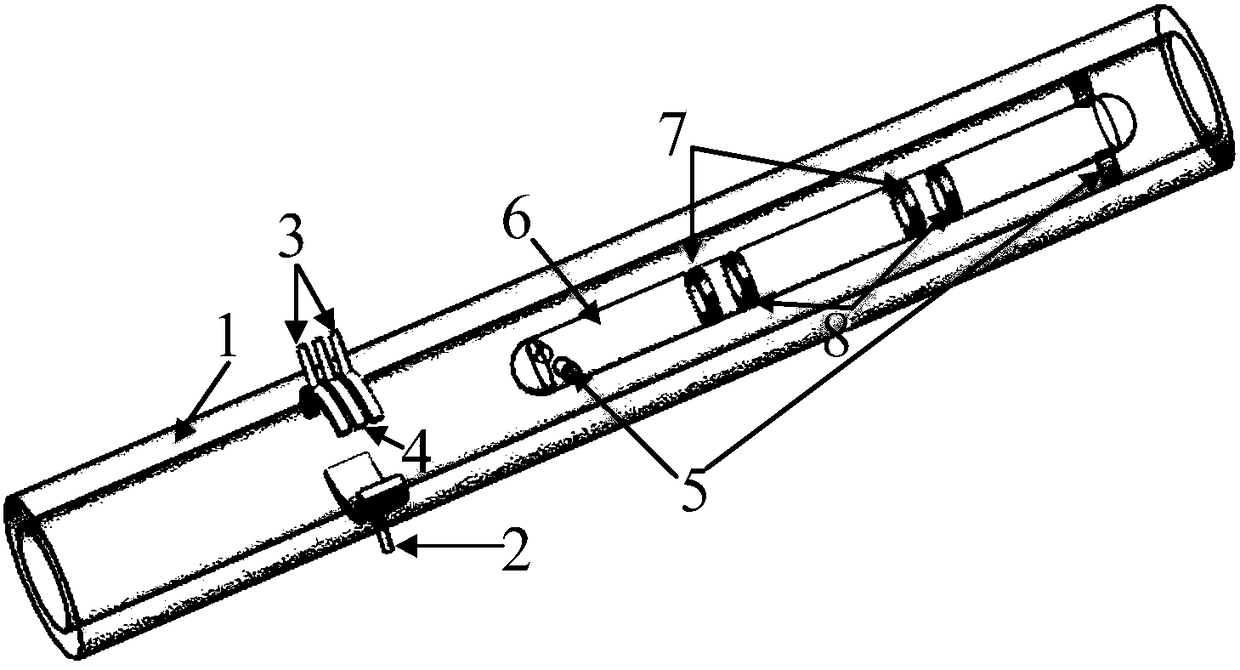

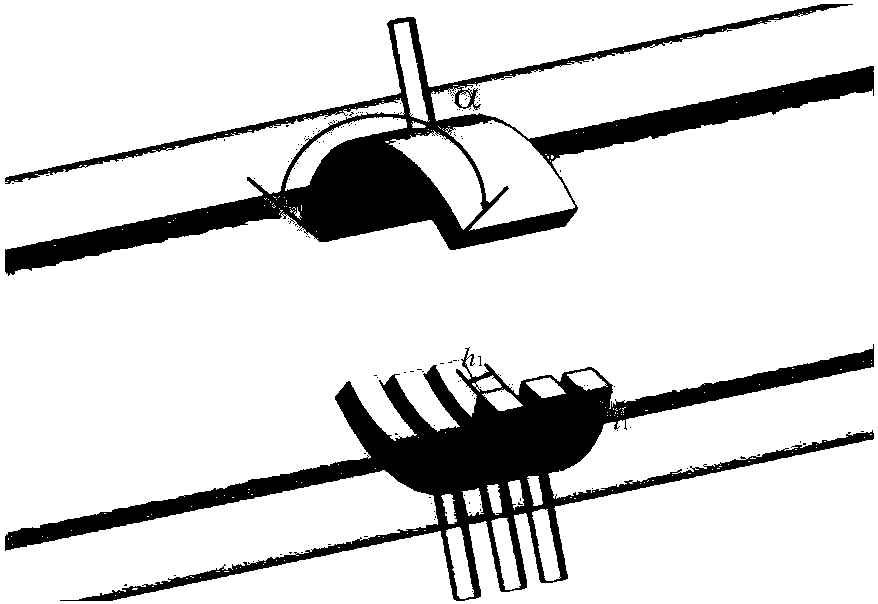

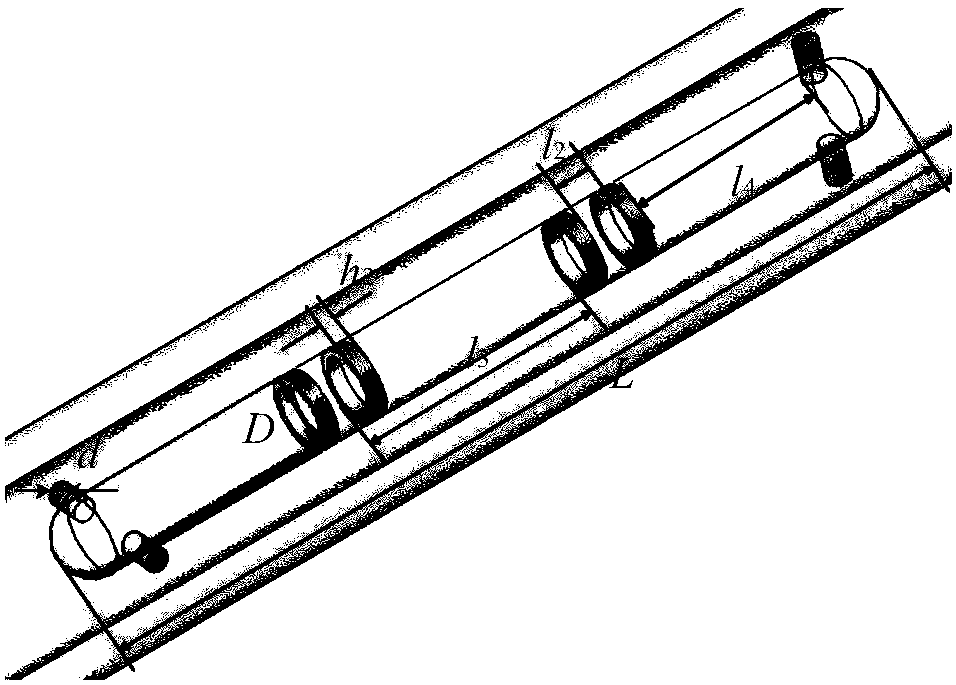

[0027] The invention proposes a method for measuring the flow rate of oil-water two-phase flow with low fluid production and high water content in oil wells. In terms of total flow measurement, an insertion-type conductance-related flowmeter is installed in the collecting channel of the collecting-type instrument, which has a significant role in flow pattern regulation and can ensure that the annular flow space between the insert body and the inner wall of the collecting channel has a stable internal flow rate. Based on the flow structure, it is beneficial to obtain the correlation between the upstream and downstream measurement electrode signals of the plug-in conductivity sensor with high reliability and repeatability. Experiments show that at low flow rates, the relative flow rate of the plug-in conductance-related flowmeter only has a good linear relationship with the total flow rate of the oil-water two-phase flow, and has nothing to do with the water cut. In terms of wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com