Water-repellent enhancing liquid as well as preparation method and application thereof

A technology of enhancing liquid and water repellent is applied in the field of resource utilization of solid pollutants, which can solve the problems that affect the subsequent use of sludge products, and it is difficult to obtain high-strength products from sludge, etc., and achieves a simple and fast preparation method, good curing effect, and application. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

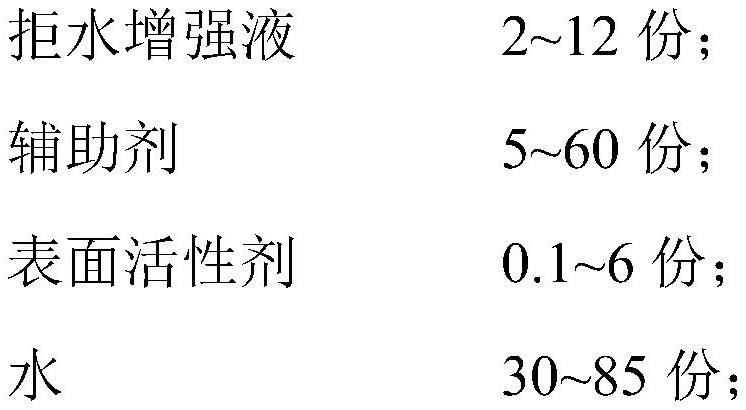

[0045] The second aspect of the embodiment of the present application provides a method for preparing a water-repellent enhancing liquid, including the following methods:

[0046] S01. Provide components according to the water-repellent enhancing liquid;

[0047] S02. dissolving the alkaline additive in water to obtain an alkaline solution;

[0048] S03. Performing a first mixing treatment on the water repellent agent and the alkaline solution to obtain a first mixed solution;

[0049] S04. The first mixed liquid is sequentially mixed with the reinforcing agent and the dispersant for the second mixing process, and then left to stand to obtain the water-repellent reinforcing liquid.

[0050] The preparation method of the water-repellent enhancing liquid provided in the second aspect of the present application only needs to mix the components sequentially. The preparation method is simple and fast, does not require large-scale equipment, and can be widely used.

[0051] In ste...

Embodiment A1

[0079] Water-repellent enhancing liquid and preparation method thereof

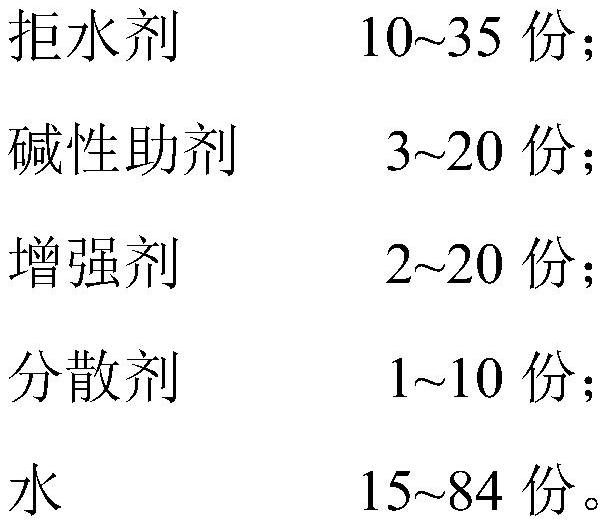

[0080] 10 parts of methyl silicate,

[0081] 3 parts sodium hydroxide,

[0082] 2 parts sodium sulfate,

[0083] Sodium lignosulfonate 1 part,

[0084] 84 parts of water.

[0085] Preparation method of water-repellent enhancing liquid

[0086] According to the above ratio, heat the water to 60-100°C in sequence, add sodium hydroxide to dissolve, add methyl silicic acid and stir for 2-4 hours, cool down to 60°C, add sodium lignosulfonate and stir for half an hour, then add sulfuric acid Stir it with sodium for half an hour, and let it stand for 48 hours at room temperature to become a water-repellent enhancing liquid.

Embodiment A2

[0088] Water-repellent enhancing liquid and preparation method thereof

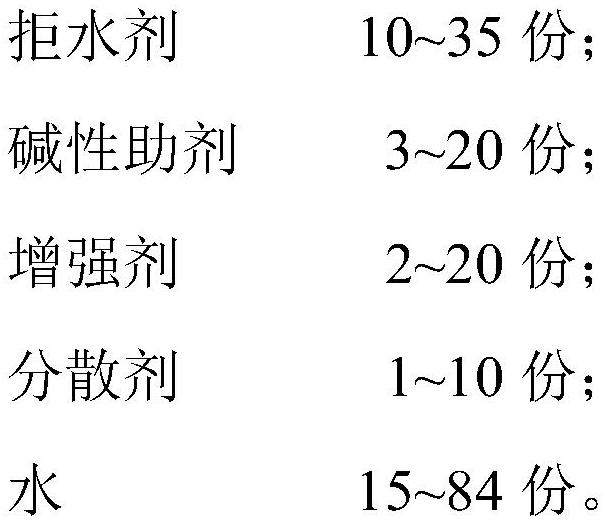

[0089] 20 parts of methyl silicate,

[0090] Potassium hydroxide 5 parts,

[0091] Sodium sulfate 10 parts,

[0092] 5 parts of sodium lignosulfonate,

[0093] 60 parts of water.

[0094] According to the above ratio, heat the water to 60-100°C in sequence, add potassium hydroxide to dissolve, add methyl silicic acid and stir for 2-4 hours, cool down to 60°C, add sodium lignosulfonate and stir for half an hour, then add sulfuric acid Stir it with sodium for half an hour, and let it stand for 48 hours at room temperature to become a water-repellent enhancing liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| void ratio | aaaaa | aaaaa |

| void ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com