Pipeline and preparation method thereof

A pipe and metal pipe technology, applied in the field of pipe and its preparation, can solve the problems of complex connection, poor external pressure resistance, poor pipe durability, etc., to solve the difficulty of pipe selection, good impermeability and durability, The effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

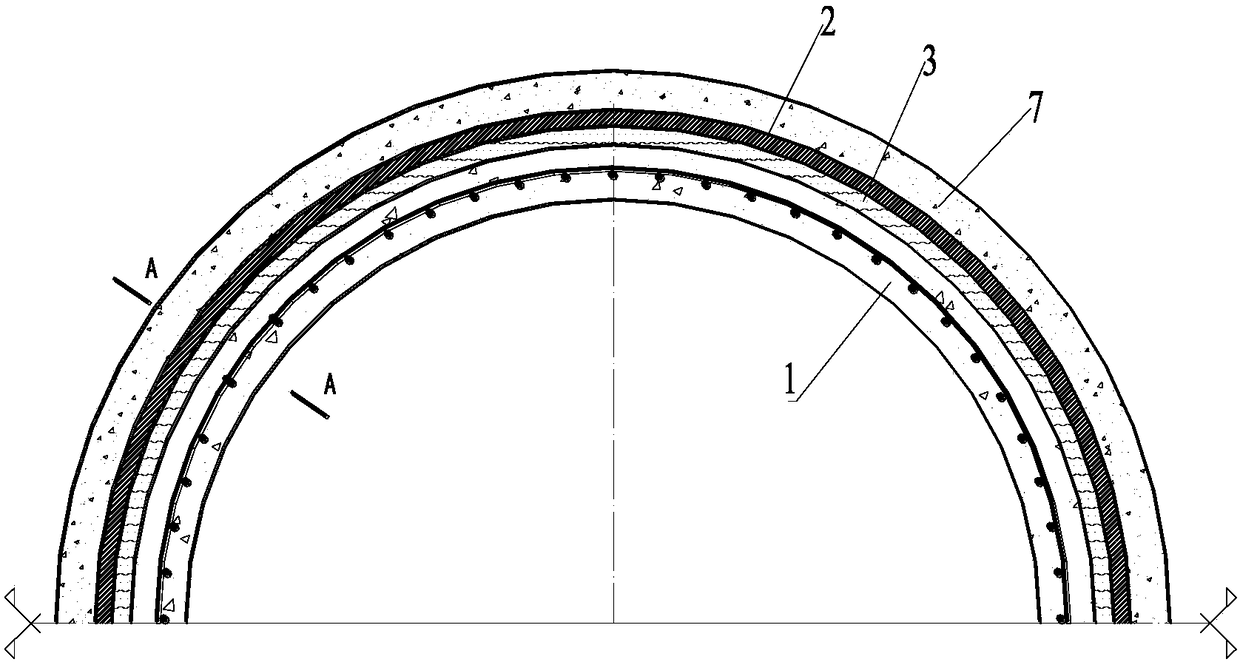

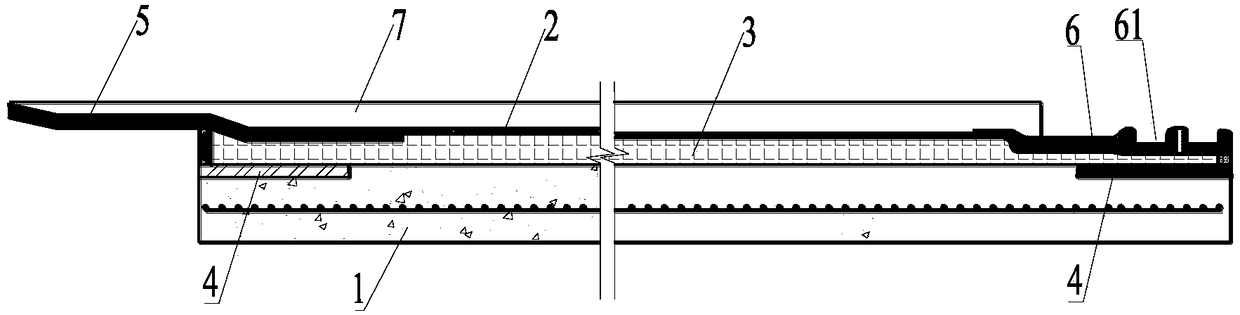

Image

Examples

Embodiment

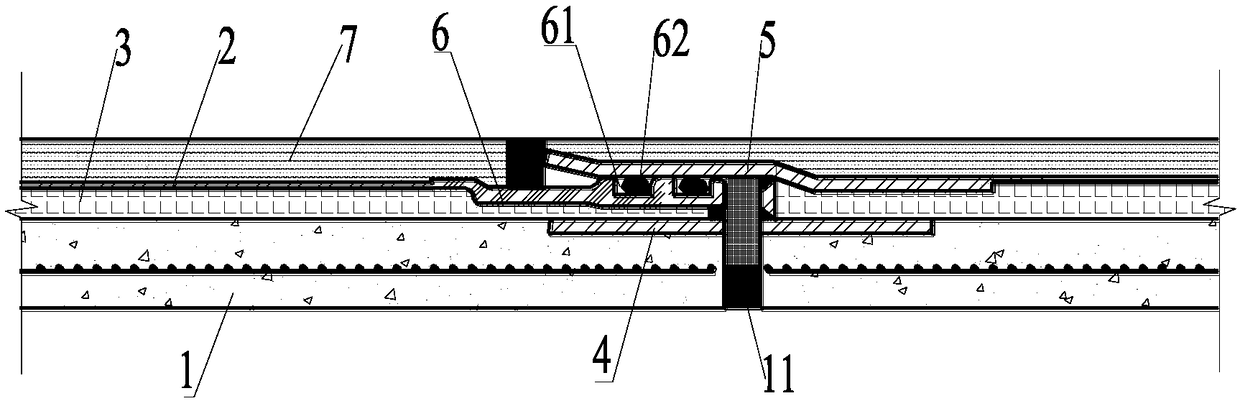

[0050] a. Preparation of socket and socket joints

[0051] Manufactured from bearing and spigot steel profiles through shearing and blanking, round welding, edge forming, rounding and other processes.

[0052] b. Preparation of metal pipes (taking steel pipes as an example)

[0053] Install the socket and socket joints processed in a on the spiral tube making machine, roll the coiled plate into steel pipes according to the design requirements, and weld them while rolling, so that the socket, socket joints and steel pipes are welded into shape at one time, and then pass the pressure test to see if there is any leakage. Missing point.

[0054] c. Preparation of concrete pipes

[0055] Bind the prefabricated steel bars, place them in the pipe mold, pour concrete, and undergo high-frequency strong vibration to make the concrete compact and form the concrete pipe.

[0056] d. Put the steel pipe prepared above on the outside of the concrete pipe, align the two ends, and weld and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com