Large-scale gas refractive index real-time measuring system

A gas refractive index, real-time measurement technology, applied in the direction of phase influence characteristic measurement, etc., can solve the problems of limited measurement range of gas refractive index, inability to realize real-time measurement of gas refractive index, and real-time measurement, so as to achieve high-precision measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

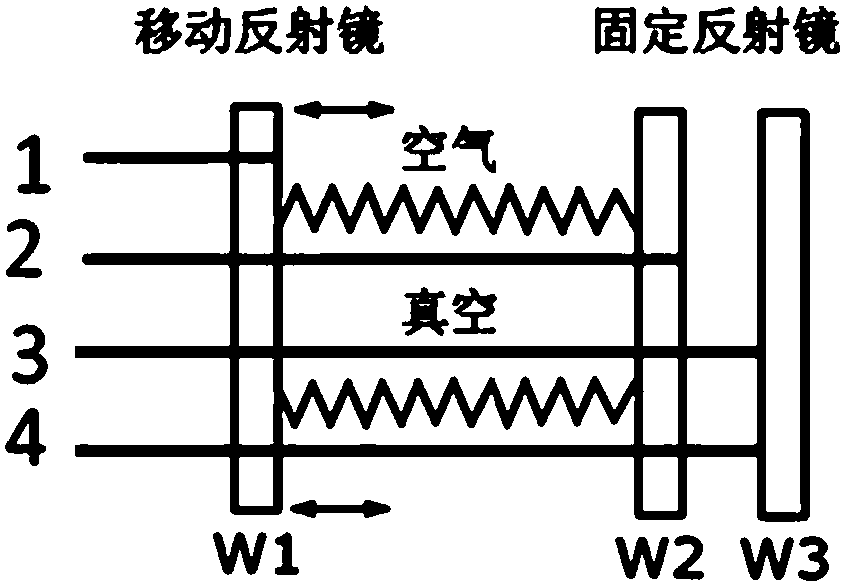

[0038] Such as figure 1 As shown, a large-range real-time measurement system for gas refractive index includes a vacuum cavity with variable cavity length and a four-way laser interference system, and its working process includes two steps: absolute measurement and real-time measurement.

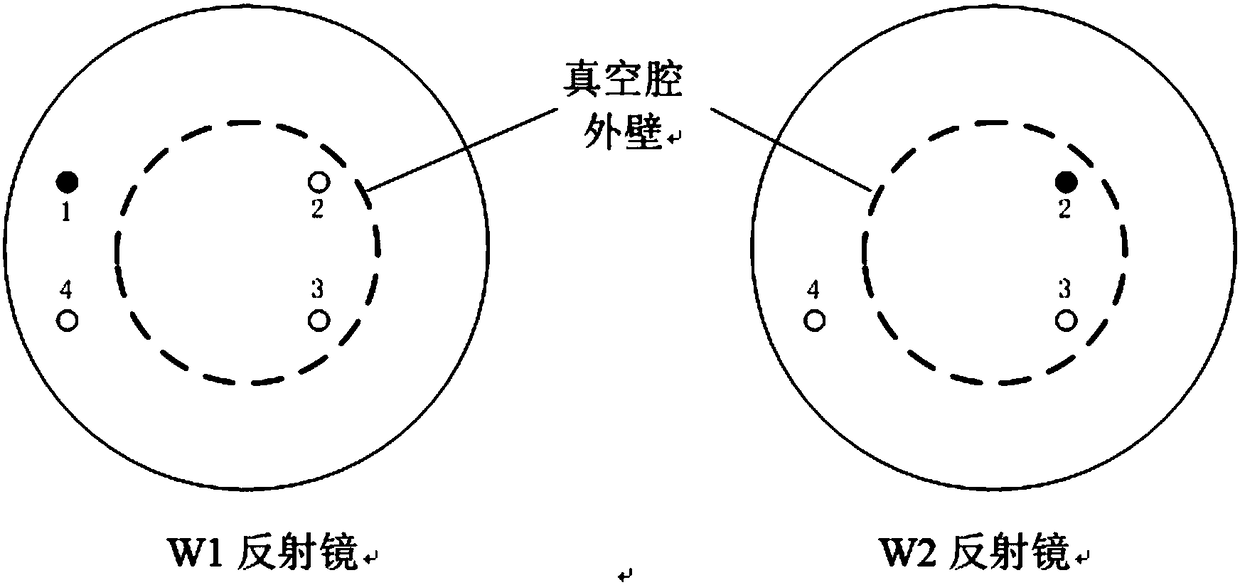

[0039] The vacuum cavity structure with variable cavity length is composed of three window lenses W1~W3, which are coated with a high reflection film for the wavelength of the laser light source and have partial transmission windows at certain positions. W1 and W2 form a vacuum chamber through bellows, W1 can be moved by motor control, thereby changing the cavity length of the vacuum chamber, W2 and W3 lenses are fixed, and there is air between them.

[0040] Mirrors W1, W2 and W3 are all coated with a total reflection film for the wavelength of the laser light source, and the mirrors W1 and W2 also have a partial transmission window, which is highly transparent to the laser wavelength.

[...

Embodiment approach 2

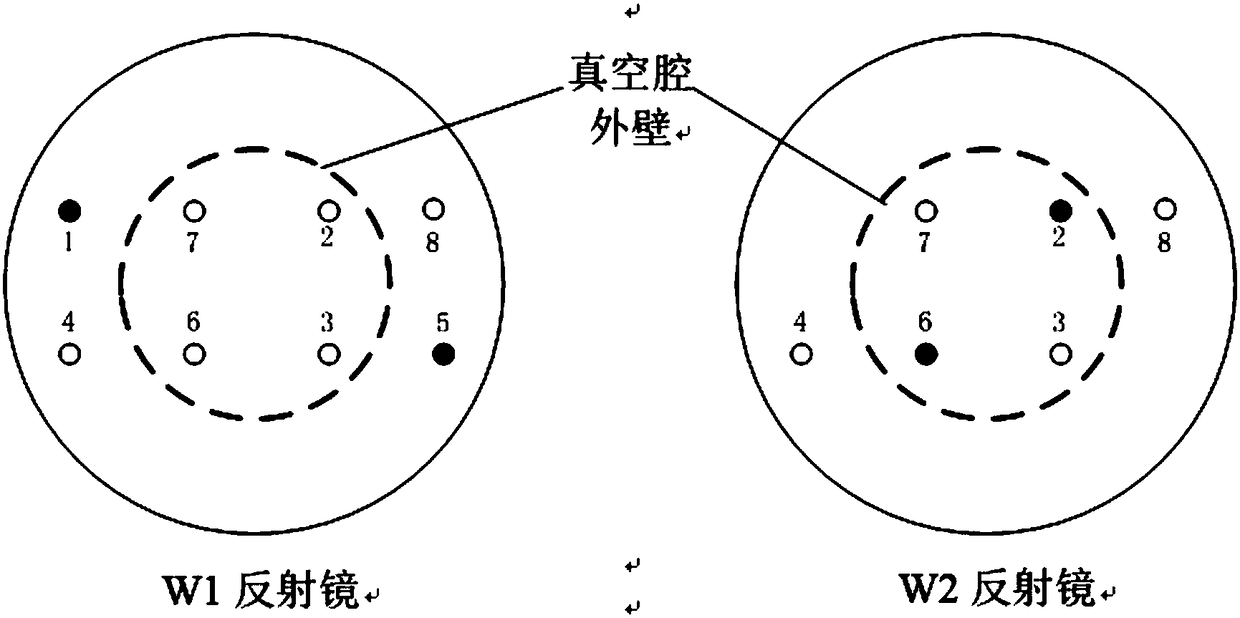

[0052] A real-time measurement system for large-range gas refractive index includes a vacuum cavity with variable cavity length and an eight-way laser interference system, and its working process includes two steps: absolute measurement and real-time measurement.

[0053] The difference between this embodiment and embodiment 1 is:

[0054] The laser interference system uses eight beams, each of which is a group of four beams, and the working principle and working steps of each four beams are exactly the same as those in Embodiment 1.

[0055] The positions of the eight beams entering the vacuum cavity are symmetrically distributed in pairs with the axis of the vacuum cavity as a reference.

[0056] Mirrors W1, W2 and W3 are all coated with a total reflection film for the wavelength of the laser light source, and the mirrors W1 and W2 also have a partial transmission window, which is highly transparent to the laser wavelength.

[0057] Among them, W1 has 6 transmission windows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com