Reflection type spectral pupil differential confocal-photoacoustic microimaging device and method

A differential confocal and photoacoustic microscopy technology, applied in the direction of microscopes, optics, optical components, etc., can solve problems such as the inability to realize cell structure images, and achieve the effects of absolute measurement, improved signal-to-noise ratio, and easy miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

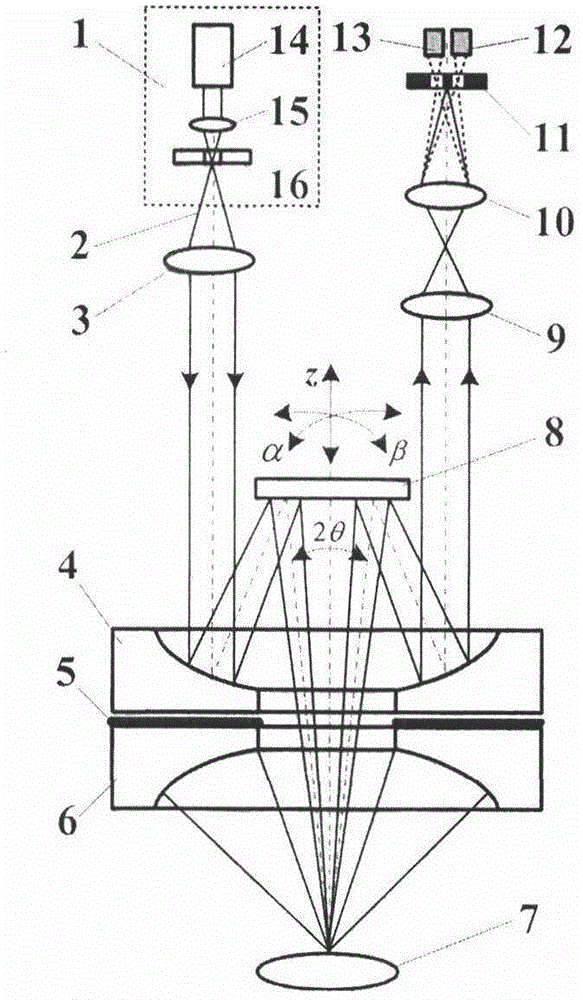

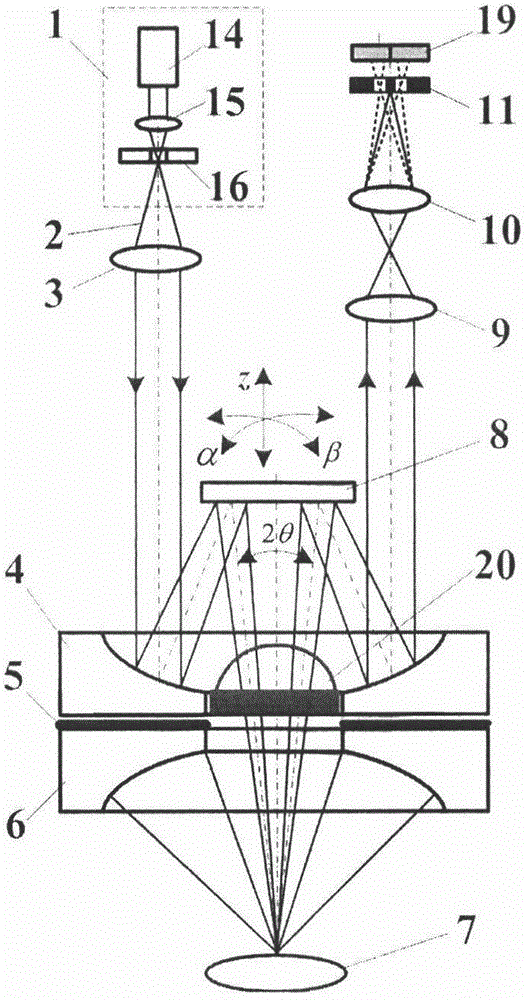

[0041] The embodiment of the present invention is based on Figure 4 The reflective split-pupil differential confocal-photoacoustic microscopy imaging device shown includes a point light source system 1 composed of a laser 14, a focusing mirror 15 placed in the laser emission direction, and a pinhole 16 placed at the focal point of the focusing mirror 15. , the collimating lens 3, reflective condenser 4, three-dimensional beam scanner 8, aberration compensating hemispherical mirror 20 and the measured object 7 are sequentially placed in the traveling direction of the pulsed beam 2, and are sequentially placed in the backscattering direction of the measured object 7 to detect An acoustic lens 6 and an ultrasonic transducer 5 for photoacoustic signals, and a reflective split-pupil differential confocal detection system for detecting backscattered light or fluorescence signals of the measured object 7; wherein the reflective split-pupil differential confocal The detection system ...

Embodiment 2

[0084] like figure 1 As shown, in the reflective split-pupil differential confocal-photoacoustic microscopy imaging device of Embodiment 1, the CCD detector 17 is replaced by a double-hole pinhole located on the focal plane of the relay lens and placed symmetrically with the double hole axis 11 , and the first light intensity detector 12 and the second light intensity detector 13 located behind the double-hole pinhole 11 detect the scattered light or fluorescence signal of the excited object 7 to be measured.

[0085] All the other measuring methods are the same as in Example 1.

Embodiment 3

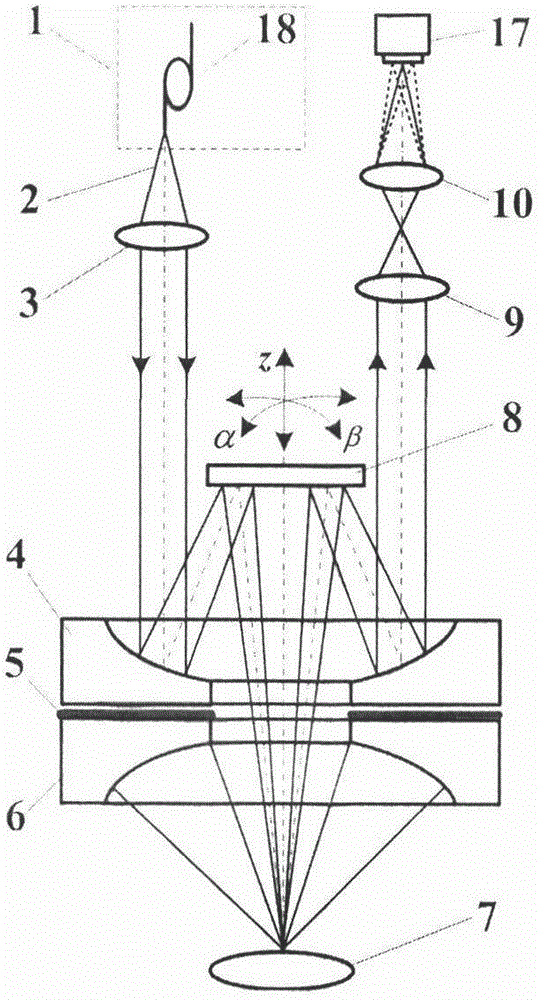

[0087] like figure 2 As shown, in the reflective split-pupil differential confocal-photoacoustic microscopy imaging device of Embodiment 1, the point light source system 1 is replaced by a fiber exiting point light source 18 .

[0088] All the other measuring methods are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com