Differential confocal scanning detection method with high spatial resolution

A high spatial resolution, differential confocal technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problem that the effect of three-dimensional super-resolution is not obvious, and achieve the effect of improving the axial resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

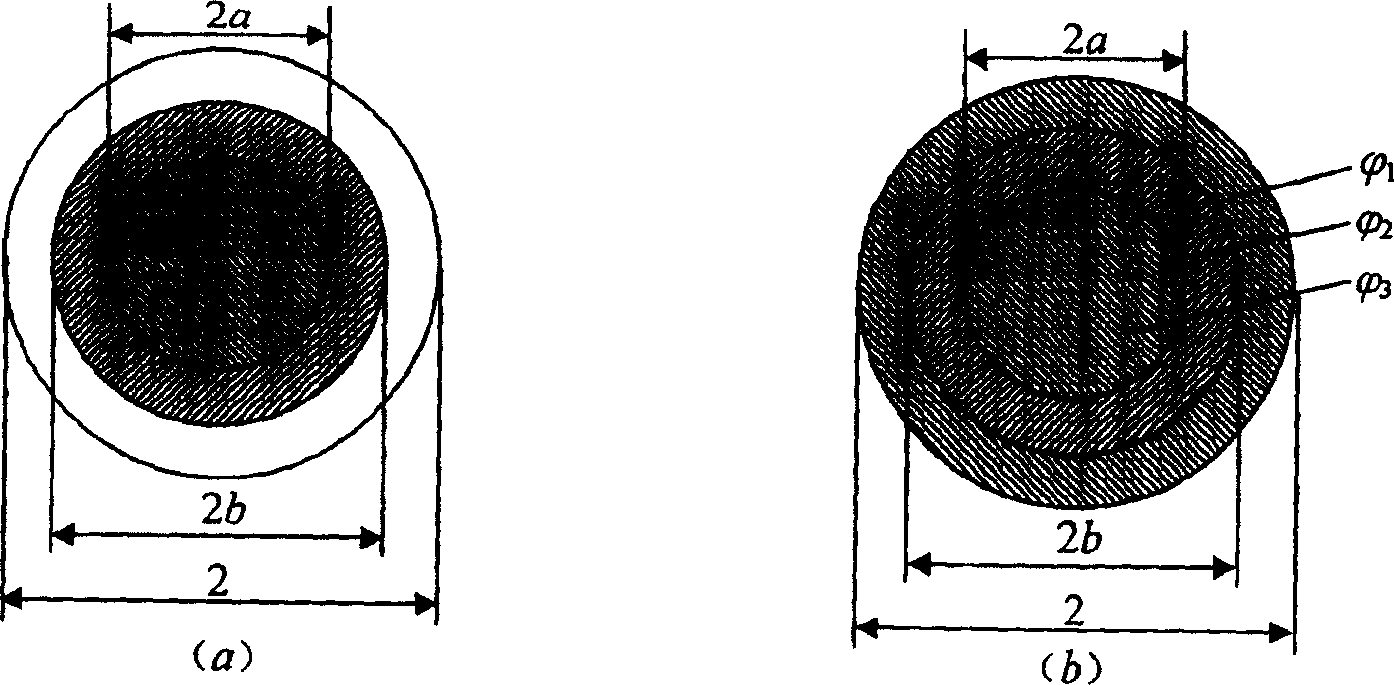

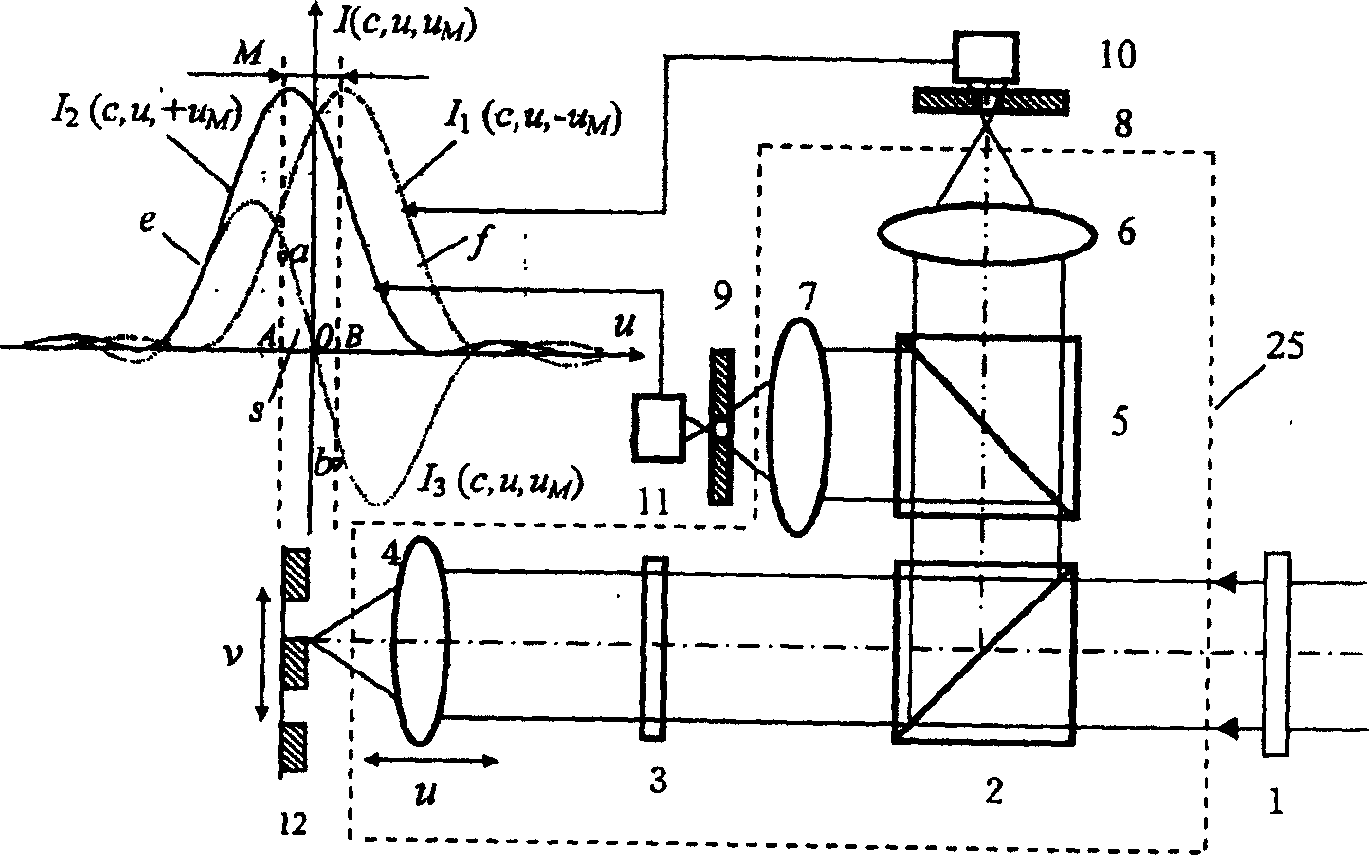

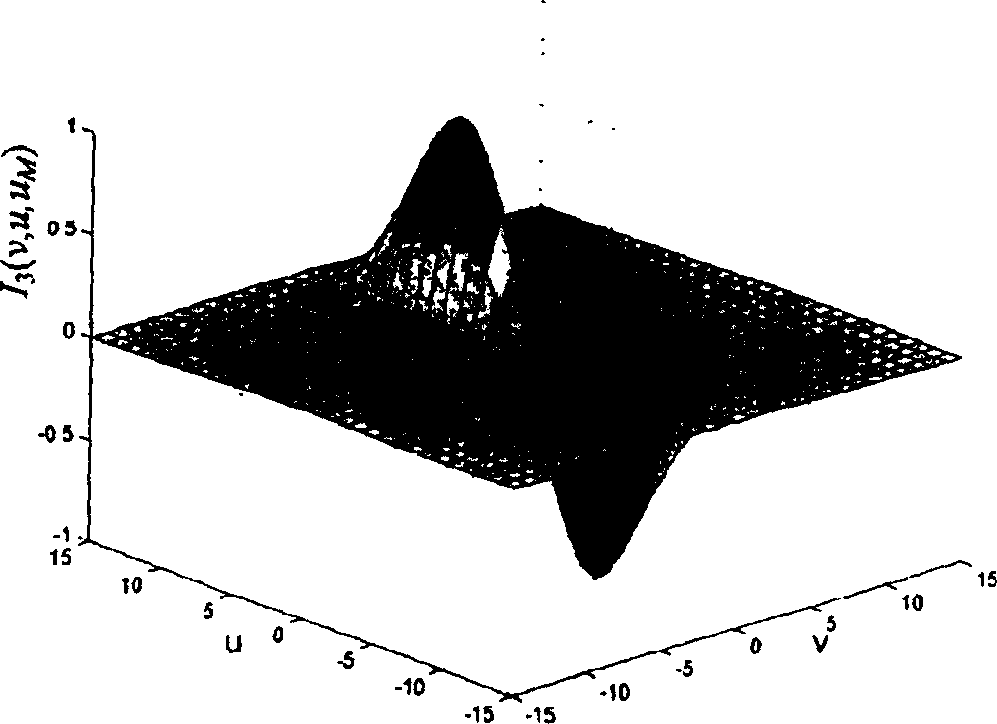

[0066] Such as figure 2 As shown, the dotted frame part is a differential confocal microscope dual receiving optical path arrangement 25, after the incident light beam is transmitted through the pupil filter 1, the polarizing beam splitter 2, and the quarter wave plate 3, the measured objective lens 4 is focused on the measured sample 12 surfaces. The measuring light reflected by the surface of the tested sample 12 is reflected by the polarizing beam splitter (PBS) 2 through the quarter-wave plate 3 again, and then divided into two beams of light by the beam splitter (BS) 5, and are respectively separated by two identical beam splitters. Condensers 6 and 7 focus. The pinhole 8 and the detector 10 are placed at the back-focus distance C of the focal plane of the condenser 6, and the pinhole 9 and the detector 11 are placed at the front-focus distance D of the focal plane of the condenser 7, and the sizes of C and D are both M, and the distance The optical normalized displace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com