Macromolecule positive temperature coefficient material assembly

A technology with positive temperature coefficient and high molecular weight, applied in the direction of heating element materials, ohmic resistance heating parts, ohmic resistance electrodes, etc., can solve the problems of difficult production of resistance, reduced usability, insufficient mechanical strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

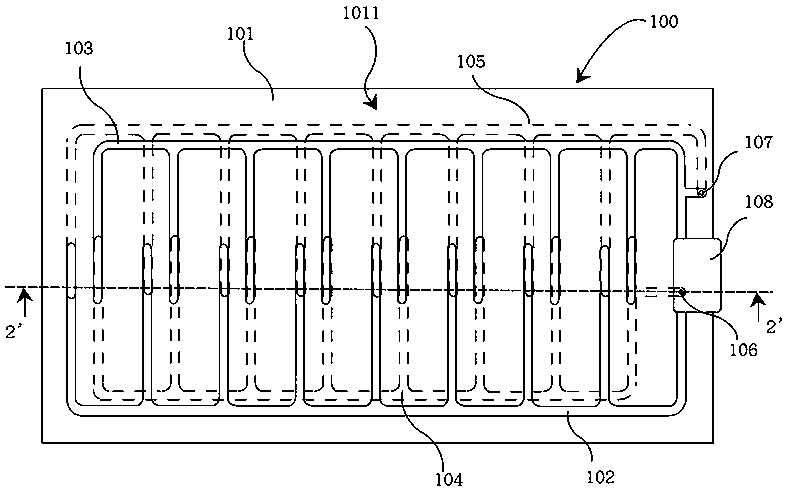

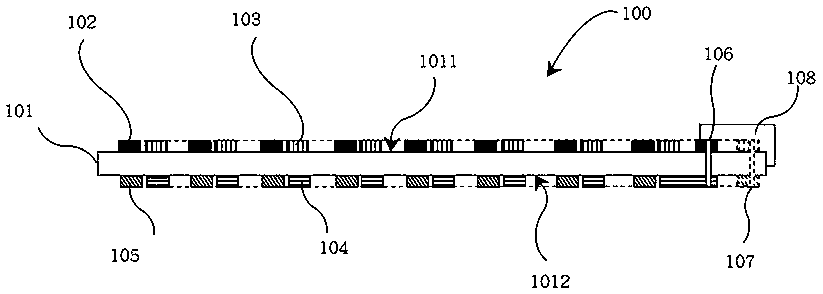

[0060] Please refer to figure 2 and image 3 shown, where figure 2 It is a top view of the polymer positive temperature coefficient component 100 according to the first embodiment of the present invention, image 3 for figure 2 Section along the 2-2' tangent.

[0061] In this embodiment, the polymer positive temperature coefficient component 100 includes a polymer positive temperature coefficient material layer 101, a first electrode 102, a second electrode 103, a third electrode 104, a fourth electrode 105, a first via hole 106, The second via hole 107 and the power interface 108 .

[0062] The polymer positive temperature coefficient material layer 101 has a first surface 1011 and a second surface 1012 . The first electrodes 102 and the second electrodes 103 are arranged on the first surface 1011 of the polymer positive temperature coefficient material layer 101 in a grid-shaped staggered manner. The third electrode 104 and the fourth electrode 105 are also arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com