Reinforced composite metal structure and moulding method and application thereof

A composite metal and metal structure technology, which is applied in the field of metal composite materials, can solve the problems of increasing the difficulty of processing, the difference in cooling speed, and the difficulty of endogenous strengthening phases to bear stress uniformly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

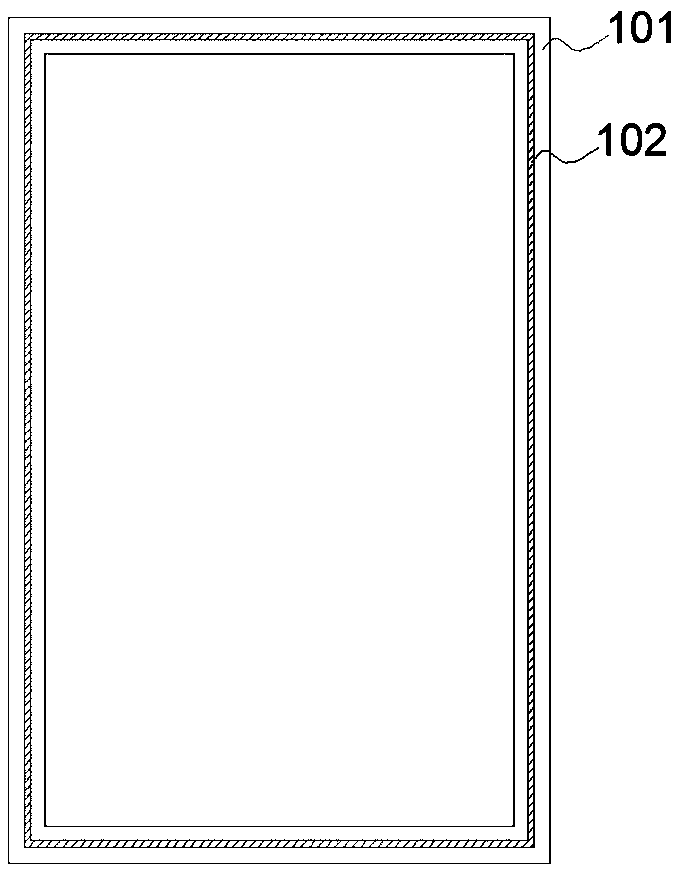

[0034] as attached figure 1 Shown is an application of the reinforced composite metal structure in the present invention. The structure is used as an outer frame of a product, and can be applied to outer frame structures such as smart phones, tablet computers, and communication products.

[0035] The structure includes a main metal frame structure 101 (a zirconium-based amorphous alloy product) and a reinforcement structure 102 . In this embodiment, the reinforcement structure 102 is a similar frame structure embedded in the outer frame 101 . . In the actual manufacturing process, when the reinforcing structural member 102 is an integral piece, it is easy to cause unevenness in the injection and pressurization of the raw materials during the processing process. Therefore, in this embodiment, the reinforcing structural member 102 is preferably set as a two-symmetrical half-frame structure The shape structure of the reinforcing structural member 102 is formed by splicing, or se...

Embodiment 2

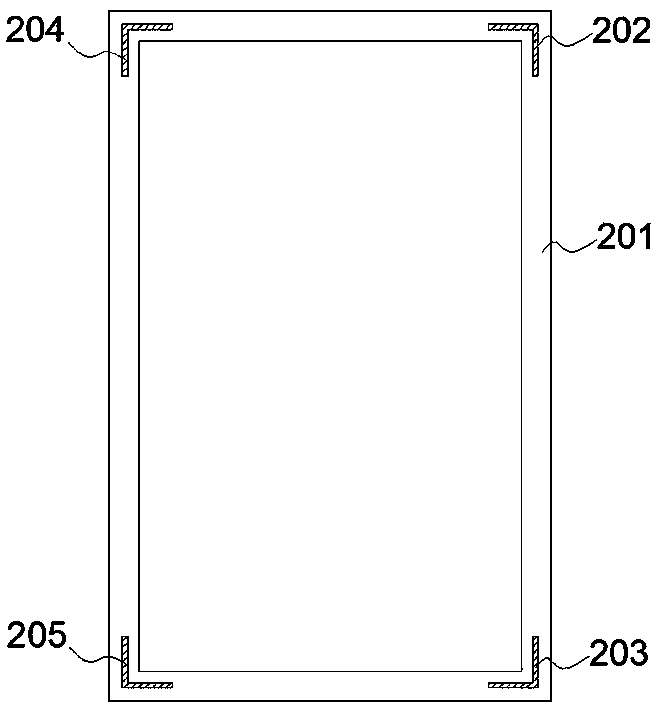

[0038] as attached figure 2Shown is another application of the reinforced composite metal structure in the present invention. The difference from Embodiment 1 is that the structure includes a main metal frame structure 201 (a zirconium-based amorphous alloy part) and a reinforced component. The strong components are angled structural members 202 , 203 , 204 , and 205 distributed at four corners of the frame structure 201 . In the frame structure, the four corners of the main metal structure are the areas that are most easily deformed by external forces. For example, the corners of smartphones are the most severely damaged and deformed in the drop test. Therefore, independent reinforcement structures are installed at the corners. It has a very good protective effect on the frame structure.

Embodiment 3

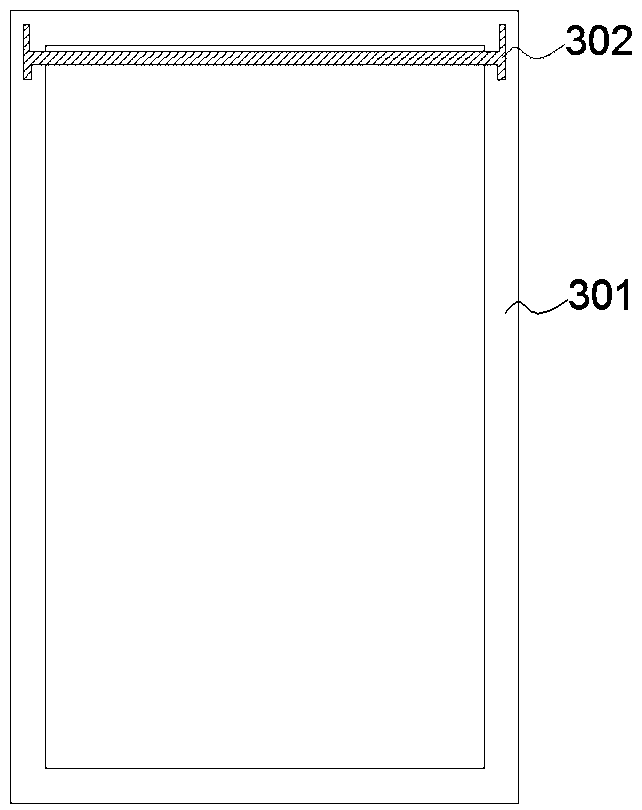

[0040] as attached image 3 Shown is another application of the reinforced composite metal structure in the present invention. The structure includes a main metal frame structure 301 (a magnesium-based amorphous alloy part) and a reinforced structural member 302, which is inlaid and composited. The frame structure 301 is reinforced in the form of outsourcing. It can be seen from the accompanying drawings that the vertical structures of the reinforcing structural members 302 disposed on both sides penetrate the frame structure 301, and the horizontal bar structure in the middle connects the vertical structures on both sides to form the reinforcing structural member as a whole, that is, the reinforcing structural member 302 is partially connected to the metal frame structure 301 .

[0041] In this embodiment, a transitional connection method can also be used, and the transitional connection method is specifically provided with a transitional connection piece as an intermediate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com