Method and system for preparing bayerite from secondary scrap aluminum ash

A technology of waste aluminum ash and bauxite, applied in ammonia preparation/separation, sustainable manufacturing/processing, chemical industry, etc., can solve problems such as landfill disposal hazards, stacking disposal hazards, and no market promotion value , to achieve the effect of protecting the natural environment and public health, huge market promotion potential, and broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

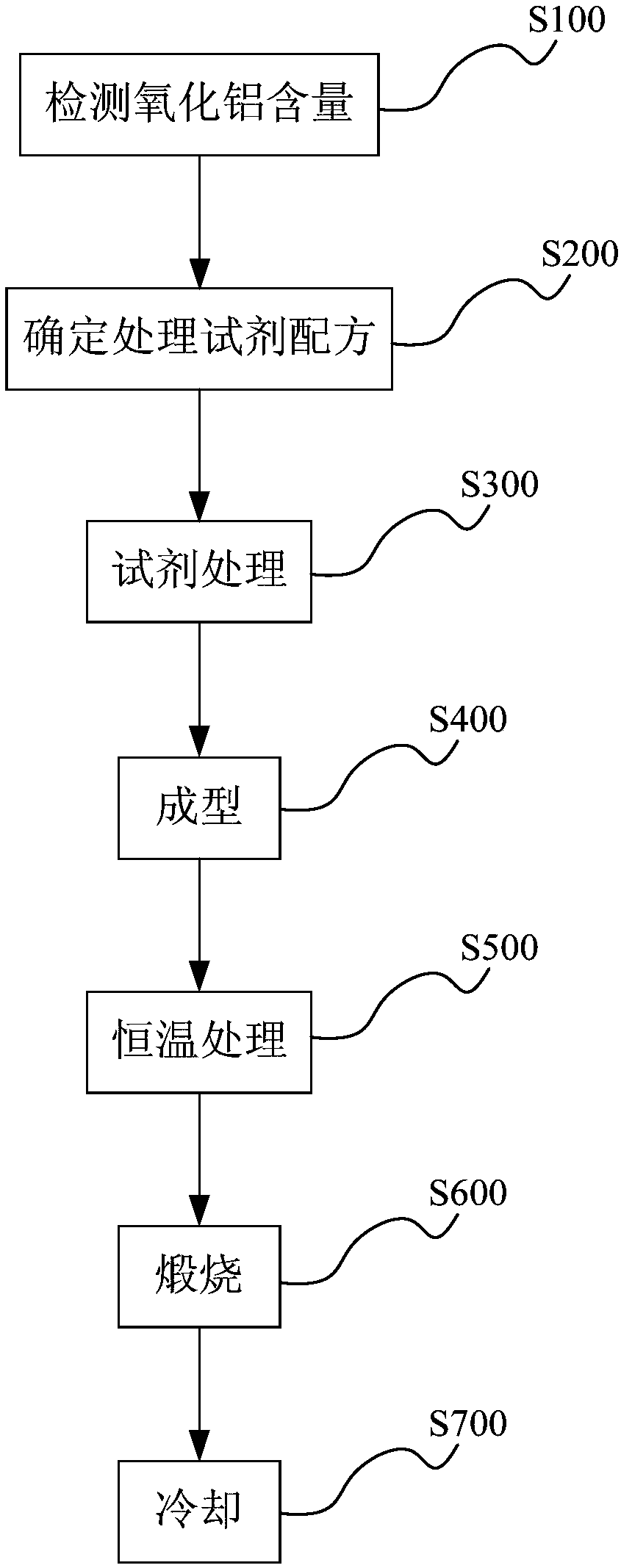

[0102] Embodiment 1: preparation of bauxite

[0103] Experimental raw materials: The secondary waste aluminum ash comes from the aluminum ash and filter residue produced by the processing of aluminum rods in an aluminum rod factory.

[0104] Steps:

[0105] (1) Detection of alumina content:

[0106] The weight percentage of alumina in the secondary waste aluminum ash is detected, and the detection method refers to GB / T6900-2006 "Chemical Analysis Methods for Aluminum-Si-based Refractory Materials". The weight percentage of alumina in the secondary waste aluminum ash is 40% .

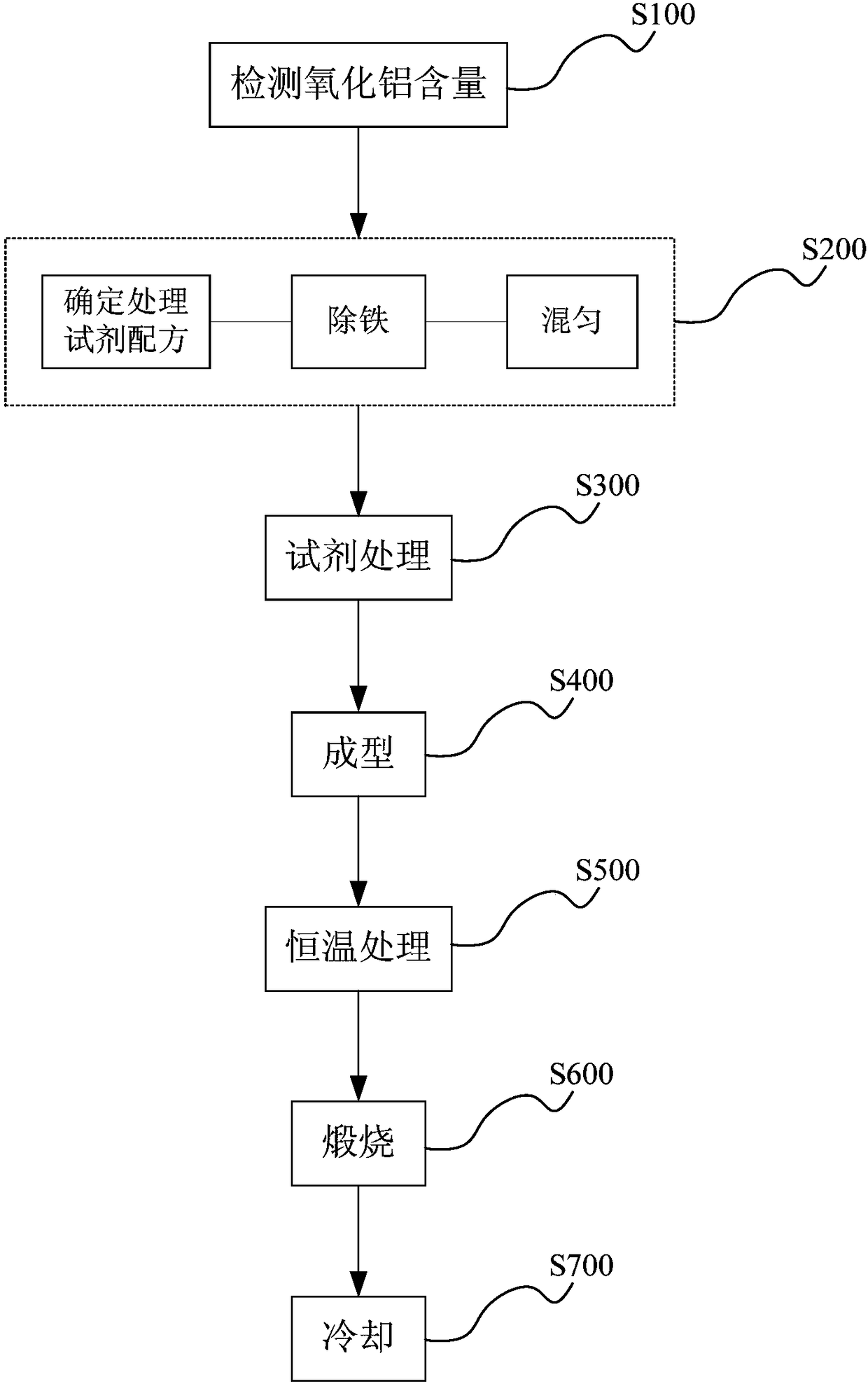

[0107] (2) Determine the treatment reagent formula:

[0108] The weight percentage of aluminum oxide in the secondary waste aluminum ash is 40%, and the weight percentage of aluminum oxide in the aluminum stone to be prepared is 70%, then the treatment reagent formula is determined as: 300 weight parts of secondary waste aluminum ash, alumina powder 150 parts by weight, a total of 50 parts by weight ...

Embodiment 2

[0120] Embodiment 2: preparation of bauxite

[0121] Experimental raw materials: secondary waste aluminum ash comes from aluminum ash and filter residue produced by aluminum alloy processing in an aluminum alloy factory.

[0122] Steps:

[0123] (1) Detection of alumina content:

[0124] The weight percentage of alumina in the secondary waste aluminum ash is detected, and the detection method refers to GB / T6900-2006 "Chemical Analysis Methods for Aluminum-Si-based Refractory Materials". The weight percentage of alumina in the secondary waste aluminum ash is 70% .

[0125] (2) Determine the treatment reagent formula:

[0126] The weight percentage of aluminum oxide in the secondary waste aluminum ash is 70%, and the weight percentage of aluminum oxide in the aluminum stone to be prepared is 70%, then the treatment reagent formula is determined as: 400 weight parts of secondary waste aluminum ash, alumina powder 50 parts by weight, a total of 50 parts by weight of bauxite an...

Embodiment 3

[0138] Embodiment 3: preparation of bauxite

[0139] Experimental raw materials: secondary waste aluminum ash comes from aluminum ash and filter residue produced by aluminum processing in an electrolytic aluminum plant.

[0140] Steps:

[0141] (1) Detection of alumina content:

[0142] The weight percentage of alumina in the secondary waste aluminum ash is detected, and the detection method refers to GB / T6900-2006 "Chemical Analysis Methods of Aluminum-Si-based Refractory Materials". The weight percentage of alumina in the secondary waste aluminum ash is 85% .

[0143] (2) Determine the treatment reagent formula:

[0144] The weight percentage of aluminum oxide in the secondary waste aluminum ash is 85%, and the weight percentage of aluminum oxide in the aluminum stone to be prepared is 75%, then the treatment reagent formula is determined as: 450 weight parts of secondary waste aluminum ash, bauxite 50 parts by weight of Yunnan white mud in total, and after the iron impu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com