Prefabricated concrete precast road capable of being recycled and construction technology thereof

A construction technology and concrete technology, which is applied to pavements, roads, roads and other directions paved with prefabricated blocks, can solve construction waste disposal and environmental protection problems, environmental dust and noise pollution, and generate a large amount of construction debris, etc., to achieve improvement Construction efficiency, reduction of construction waste, effect of reducing waste and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

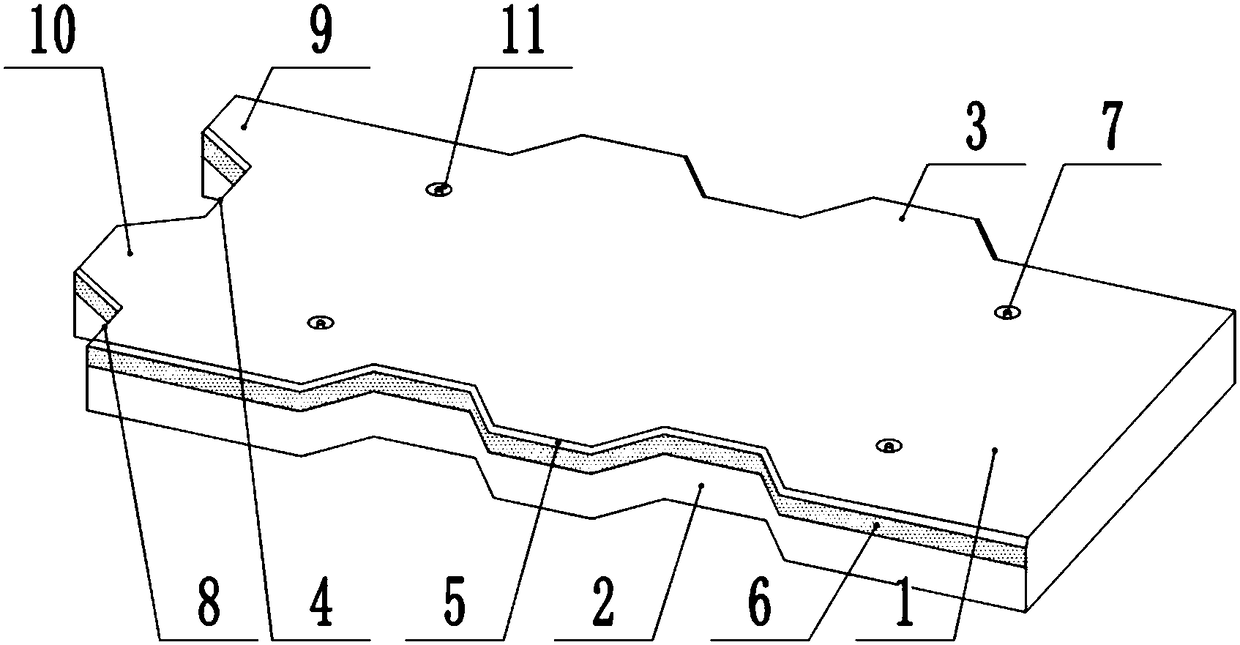

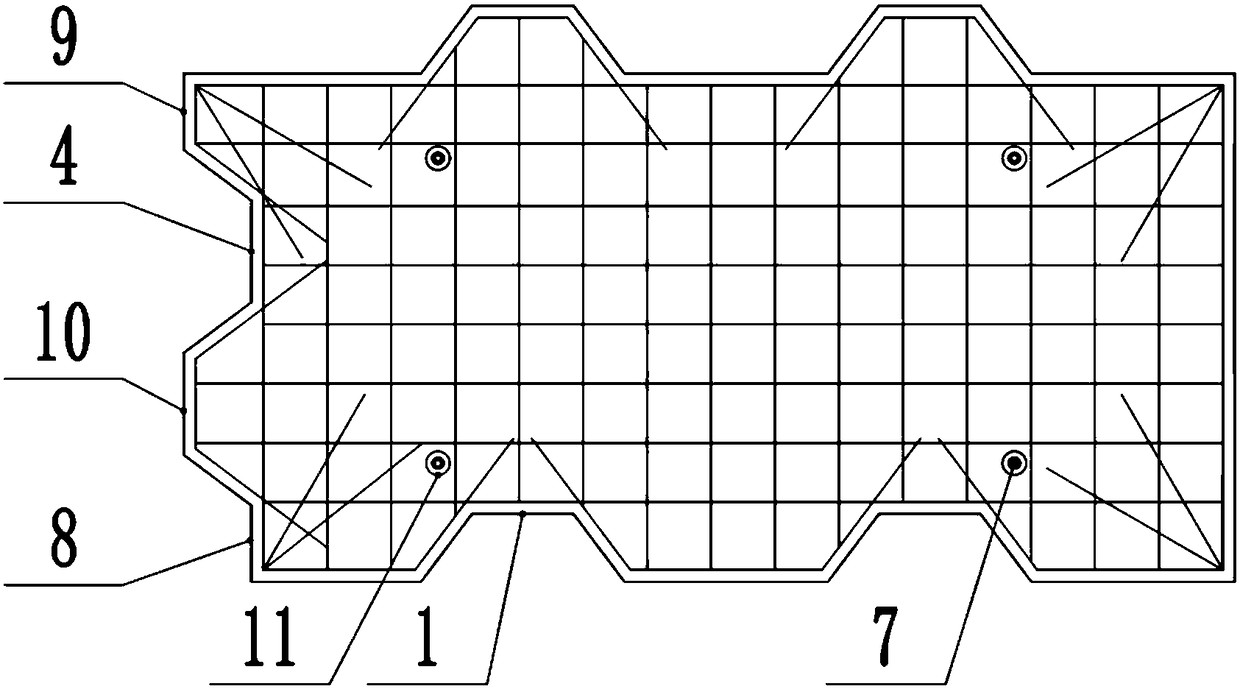

[0029] like Figure 1 to Figure 3 as shown,

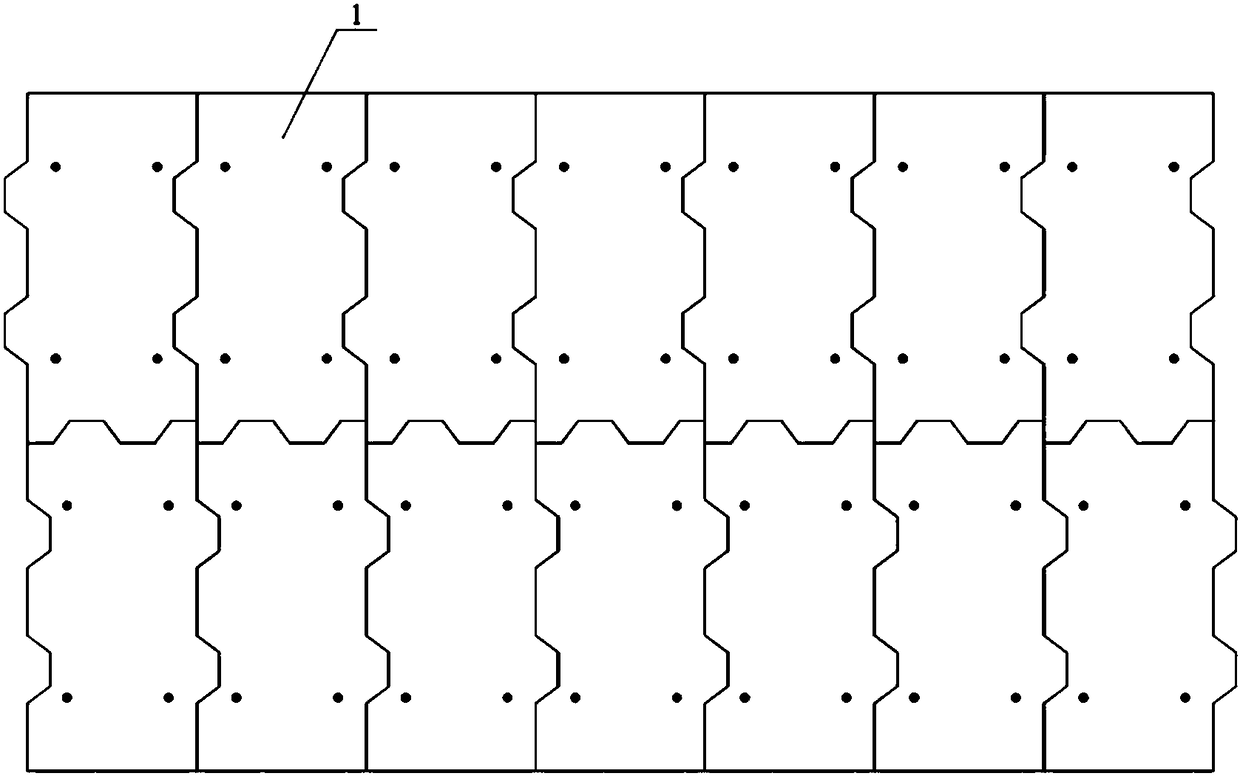

[0030] A recyclable prefabricated concrete road is formed by splicing several prefabricated concrete slabs 1, the front side of the prefabricated concrete slab 1 is provided with two grooves 2, and the rear side of the prefabricated concrete slab 1 is provided with There is a protrusion 3 corresponding to the tongue and groove 2 on the front side. The left side of the precast concrete panel 1 is provided with a first card slot 4 and a second card slot 8. The first card slot 4 and the second card slot 8 The setting makes the left side of the concrete prefabricated slab 1 form a first protrusion 9 and a second protrusion 10, the shape and size of the first protrusion 9 are consistent with the shape and size of the second clamping groove 8, and the first protrusion 9 The shape and size of the two protrusions 10 are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com